U.S. Army tests RFID technology for inventory of medical items in refrigerators

[ad_1]

Recently, it has been reported that a US Army research institute has been testing an RFID solution that allows highly sensitive samples to be counted without leaving the freezer for the past two years. Currently, this research uses UHF RFID electronic tags and UHF readers. Everyone knows that when experimenters take out some of the most sensitive biological samples stored in the laboratory from the freezer, the temperature of the sample will rise even for only one minute, so it is very useful to take inventory under the freezer. necessary.

The institute addresses the biological threats of the U.S. military and develops medical countermeasures. They employ military and civilian scientists, cooperate with the Centers for Disease Control and Prevention, the World Health Organization, and multiple biomedical and academic institutions around the world. Part of the work performed by the first-level laboratories includes the development of medical solutions, such as vaccines and drugs, and the study of biological selection agents and toxin samples.

In general, inventory management means that every time the staff inspects and records a sample, they must take the sample out of the freezer, visually confirm the information of each sample with the naked eye, and then put the sample back into the freezer. However, this manual inspection method is time-consuming, labor-intensive, error-prone, and also poses a risk to the integrity of the sample.

Normally, samples must be stored at -80°C (-112°F) or lower. “When they are taken out of the freezer, once the temperature starts to rise, the samples will degrade. Therefore, in addition to accountability, the laboratory also needs to maintain the integrity of the biological samples as much as possible,” the relevant staff explained .

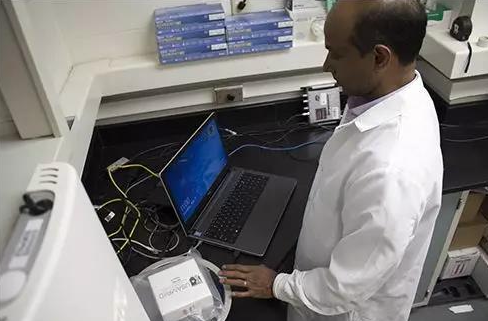

The purpose of the institute is to use RFID technology to track all samples. What is needed is not a manual statistical sample, but a solution that can read hundreds of samples at the same time. At present, the institute is mainly focused on testing hardware components, including numerous UHF RFID electronic tags and UHF handheld terminals. At the same time, the team is exploring whether it can be scanned without opening the freezer.

It is worth mentioning that many samples are composed of liquids or stored in environments surrounded by metals, so the research team has been testing which label is most effective in these environments. Researchers need to read the tag every month to determine whether the sensitivity of the tag will decrease over time in an extremely cold environment.

Currently, the research is still being tested, and they have not yet tested any temperature-sensing RFID tags. On the one hand, it can significantly reduce the time required to take inventory, on the other hand, it can eliminate manual inventory and maintain sample integrity, thereby reducing the incidence of human error. If it succeeds, it will undoubtedly be a major technological breakthrough.

[ad_2]