Informatization construction of combat readiness warehouse of an armory in Sichuan Province

[ad_1]

In order to realize the systemization, standardization and automation of unit warehouse management, an armory in Sichuan Province combines unit equipment management requirements, actual daily use needs and actual investment conditions, based on video surveillance technology, access control technology, environmental monitoring technology, video linkage technology, guns Cabinet management technology, RFID and barcode technology, customized development of a war-ready warehouse management system.

1. Construction goals

1. Build a standardized intelligent warehousing system

Aiming at the characteristics of the large variety and large quantity of warehouse materials, an intelligent management system integrating personnel management, warehousing, outgoing, shifting, inventory counting, security and other operations is built. Use the system process as the system to ensure the standardization of each link of warehouse management, get rid of the interference of human factors, and ensure the accuracy of data in each link.

2. Realize the visualization of material management

All cargo information in the warehouse can be updated in real time, so that business departments at all levels can see the situation of the unit’s warehouse at the same level in real time through the local area network, and understand the storage time and status of inventory materials. Provide a basis for various departments to formulate warehousing plans in a timely and accurate manner; 2D/3D graphical interfaces should be used to display situational information, and provide graphical displays of events, locations and scope of influence.

3. Multi-system integration-PSIM management platform

The PSIM management platform realizes the integration of multiple systems such as video surveillance system, access control system, environmental monitoring system, RFID material management system, gun cabinet management system, and barcode management system into the same platform to realize the linkage between various systems;

The PSIM management platform has powerful front-end equipment access capabilities, and can integrate different systems from several levels: data, signaling control, media transmission, and terminal application;

The PSIM platform must be able to obtain, change, backup and restore the device parameters of various connected subsystems;

The PSIM platform should be able to provide a step-by-step execution plan and respond according to pre-established rules;

The PSIM platform must have redundancy functions, support disaster recovery, fault migration, ensure business continuity, and support unified network management functions.

2. Project requirements

1. Material management function

In the combat readiness warehouse management system, the information and status of different shelves and different materials can be displayed graphically. In the case of emergency dispatch, it ensures accurate and rapid material transfer, saves time to the greatest extent, and visually displays the condition of all items.

2. Automatic inventory function of materials

During the inventory process, the warehouse clerk installs tags on large items or boxes, and reads them through a remote card reader; small items or small items in the box are affixed with barcodes or labels on the surface, and use a handheld reader to read them. Material information can be easily read, inquired, edited, added and deleted, and updated in real time.

3. Material storage management function

Material storage includes two parts: new material storage and outgoing material storage;

New materials are put into the warehouse, and the materials are coded regularly, and the codes are given labels, and the labels or bar codes are fixed to the materials or boxes to ensure that the management system is updated in real time. Place the materials that have been coded, labeled, and entered information on the agreed shelves in accordance with the rules, complete the storage, and generate the storage list.

For the re-entry operation of outbound materials, the loss of materials can be updated in real time through the system. The materials read by the handheld reader will automatically complete the warehousing operation, and finally placed on the agreed shelf according to the rules to complete the warehousing.

When the materials are put into storage, if you forget the location, use the control machine or PDA to inquire, confirm the location through the sound and light alarm device (installed on the shelf or the cargo space), and place the new materials.

4. Material delivery management function

Material delivery includes two parts: daily delivery and task plan delivery;

Daily materials out of the warehouse, for daily applications, submit materials applications, and a small amount of materials will be out of the warehouse after approval. The warehouse manager reads and scans the outbound materials through a handheld reader or a remote fixed card reader according to the material outbound list.

The task plan is out of the warehouse. If there is a task training or battle, the system will carry out the material out of the warehouse according to the preset plan. The material will reach the warehouse door and read it from a distance to automatically confirm the out of the warehouse. The system judges the material to be out of the warehouse and automatically modifies it. Material status; the system has a reminder function and can generate corresponding reports.

When the corresponding materials are not found when leaving the warehouse, use the control machine or PDA to inquire, confirm the location through the sound and light alarm device (installed on the shelf or the cargo space), and the administrator picks up the goods at the corresponding location.

5. Material query function

The warehousing management system can query real-time information such as the status of materials in and out of the warehouse, the quantity and quality of all materials, the intact rate, and the records of material usage, providing more valuable and time-sensitive analysis data for material calling decisions.

6. Sub-authority management function

According to different personnel permissions, it has different management functions. Through the system, the leader can inquire about the real-time situation of each unit’s warehouse materials, such as the quantity, status, and in and out of warehouses. The person in charge of the warehouse can inquire about the quantity, status, and access status of the warehouse materials of the unit, and has the authority to review and approve materials out of the warehouse. The warehouse manager can inquire about the quantity, status, and access status of the warehouse materials of the unit, and enter the warehouse materials information. The system administrator can inquire about the quantity, status, and access conditions of the warehouses of each unit, and can perform user management.

7. Access control management function

1# vehicle maintenance warehouse, 2#armory, 3#, 4# and other entrances are equipped with fingerprint access control or face recognition access control, and smart locks can realize multiple opening methods and multiple security protections. To open or close the warehouse door, two openers press their fingerprints on the fingerprint access control machine. The staff on duty responds to the door opening request through the three-level network of the corps and pops up real-time video monitoring to confirm the staff. After the authorization is granted, the opener turns the lock to complete the opening.

Through the PSIM platform, you can log in, delete fingerprints, link alarms, open the door remotely, query the door opening record, lock and unlock the screen and other operations.

8. Warehouse environment monitoring function

There are smoke alarms, temperature and humidity material tags, strong earthquake sensors, three-monitoring alarm tags and other equipment installed at multiple points in the warehouse. These equipment transmit relevant data information through ZigBee networking, and transmit real-time data to the monitoring center through signal relay. If the preset threshold is exceeded, the system will automatically alarm, and record the corresponding alarm form in the corresponding alarm form, according to the different alarm levels, the measures taken are also different.

9. Video surveillance function

Gun-type cameras and 360-degree controllable rotating cameras are installed in and around the warehouse to form an all-in-one, non-dead-angle monitoring of the warehouse and its surroundings. The monitoring video is stored for more than 3 months, and it is connected to fire alarms, access control systems, and RFID access. The library management, wall shock alarm and other systems are linked, and the video situation of the corresponding alarm location is directly displayed on the PSIM management platform.

The materials on the video surveillance shelves show that the camera has been moved, the warning line has been exceeded, the materials have been moved, and there are suspicious materials. After the video analysis, an alarm is generated and an alarm list is formed, and an alarm window pops up to remind the warehouse manager.

10. Other functions

In order to prevent personnel from maliciously operating the system, the warehouse management system should provide convenient and effective data backup and recovery functions, have redundant functions, support disaster recovery, fault migration, ensure business continuity, support unified network management functions, and provide for personnel Log the operation process and long-term backup.

Three, system description

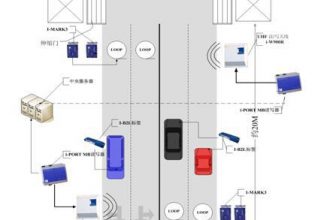

The information management system of an armory combat readiness warehouse in Sichuan Province includes: access control system, video monitoring system, environmental monitoring system, RFID material management system, gun cabinet management system, barcode management system and other systems integrated into the same platform, system structure The picture is as follows:

1. Fingerprint facial recognition access control and alarm system

Each warehouse is equipped with fingerprint access control or face recognition access control, with smart locks to achieve multiple opening methods and multiple security protections. To open or close the warehouse door, two openers press their fingerprints on the fingerprint access control machine. The staff on duty responds to the door opening request through the three-level network of the corps and pops up real-time video monitoring to confirm the staff. After the authorization is granted, the opener turns the lock to complete the opening.

2. Main functions

Link with video surveillance system, remote login, delete fingerprint function, linkage alarm function, remote direct open function, open door record query function, emergency key password management box system.

3. System composition

Warehouse duty room: access control main control computer, joint management and joint control system software, GSM main control machine, emergency key management software, USB fingerprint collector.

Warehouse: dual communication control terminal, access control machine, separate mechanical lock, network high-definition camera, 360-degree rotating controllable dome, emergency password management box, door sensor, warning light, three-monitor alarm system, smoke alarm, temperature and humidity Material label, wall shock alarm, temperature and humidity acquisition server, security equipment integration server.

4. Opening method

1) Normal door opening process

The unlocker enters the unlocking fingerprint to apply for the network, the main control computer in the duty room will automatically pop up the unlocker application dialog box, sound a voice prompt, and automatically pop up the live video. After confirming the on-site situation, the attendant issues an unlocking instruction, and the opener directly turns the handle to complete the unlocking.

2) The unlocking process in case of sudden emergency or when the unlocking personnel are not in place

The opener sends a direct application via the phone. After receiving the call, the attendant turns on the monitor to confirm the on-site situation and enters the fingerprint to issue a direct unlocking instruction. The opener does not need to enter the fingerprint and can directly turn the handle to complete the unlocking.

3) The unlocking process when the third-level network is abnormal or the unlocking personnel are not in place

The system will automatically switch to the GSM special network mode, and the unlocking can be completed by operating in accordance with the above methods.

4) The unlocking process under abnormal conditions in both networks

The duty officer can call out the random authorization code generated in advance for each weapon room in the system software, and inform the opening personnel by telephone. The opening personnel can use this password to authorize themselves, and then enter the fingerprint to complete the unlocking. This password can randomly generate a new password when the third-level network is normal.

5) The unlocking process in the case of complete failure of electronic equipment

The unlocker applies for the emergency key to open by phone. The attendant uses the emergency key management software installed on the computer in the duty room to generate a password, and informs the unlocker. The unlocker uses the password to open the emergency. The one-time password is automatically invalidated.

5. The effect can be achieved after implementation

1) Dual network communication function, dual communication guarantee of tertiary network and GSM network.

2) Video monitoring function, when the warehouse is opened, the corresponding video images of the warehouse can be automatically popped up, and all the videos inside the warehouse can be viewed through the video monitoring software, and the fast dome can be controlled to monitor the internal pictures.

3) Password authorization function. When both networks are abnormal, the authorization password can be used to authorize the access control system. This password will automatically become invalid once used and a new password will be produced.

4) Linkage alarm function. The warehouse is equipped with door magnetic alarm, smoke detection alarm, three-monitoring alarm label, and strong shock alarm, which can alert the warehouse in all directions, automatically upload various alarms and real-time records and generate sound and light alarms.

5) Emergency key password management box, including a set of detachment password management software and key management box. Without relying on any network, the password is generated through the software installed on the detachment computer to control the opening of the squadron password management box. This password is automatically invalid once used, which solves the problem of key management.

6) The mechanical lock adopts our company’s patented technology, driven by a pulse self-holding electromagnet, the door opening handle is separated from the lock body, and the five-sided design is adopted, which is difficult to open without special tools. It virtually adds another layer of security to the fingerprint lock. .

[ad_2]