The U.S. Department of Defense will use miniature RFD chips for authenticity verification of electronic components

[ad_1]

Northrop Grumman is in charge of a four-year project for the US Department of Defense Advanced Research Projects Agency (DARPA). The company is developing a miniature RFID chip to prevent counterfeiting of electronic parts on circuit boards on avionics or other equipment. Northrop Grumman Consulting Engineer Scott Suko explained that the purpose of the project is to develop a near-field HF RFID product. The chip size is 100 microns * 100 microns, including an on-board antenna and temperature sensor, which can be embedded in an integrated circuit or circuit board. The entire system—including chips, RFID readers, and special software—was developed for the integrity of the supply chain hardware of DARPA’s Electronic Defense (SHIELD) program, and to combat counterfeiting and counterfeiting of electronic parts sold to the U.S. government or commercial companies .

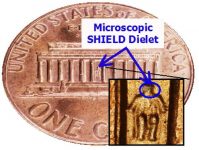

The size of the chip is similar to the size of the Lincoln head on the reverse side of the 1 cent Lincoln commemorative coin. In fact, a wafer with a diameter of 300 mm can be cut into 3.5 million chips.

After the project is completed in 2019, DARPA expects that the chip will be used to verify the authenticity of small electronic devices, including integrated circuits used in defense and industrial fields.

Suko said: “This is a big problem.” Old electronic parts may pretend to be new parts, which threatens the effectiveness of the equipment. The US Department of Defense (DOD) has taken steps to develop new technologies to prevent counterfeit parts in the US supply chain. DOD treats this as a priority.

With the help of RFID Global Solutions, Northrop Grumman is developing a solution to identify and determine the authenticity of electronic components. The tiny die has an encrypted ID number and a sensor that can confirm the authenticity of the product. RFID Global will also develop electronic parts certification applications based on the Visi-Trac software platform.

Sandia Laboratories also developed a thin-film temperature sensor that can detect temperatures above 220 degrees Celsius, which is the threshold for electronic parts manufacturing or remanufacturing processes. When the RFID reader reads the RFID chip, such a high temperature will cause the sensor resistance to change. When the reader detects the change, it may indicate that the temperature has reached the manufacturing level multiple times), which warns that the electronic parts may be counterfeited or old parts are used.

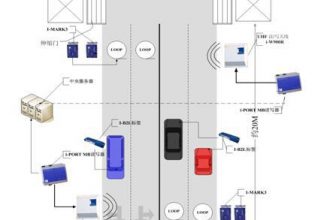

The chip will be placed at the part mark position that needs to be tracked.Then, the company will also use a cheap near fieldRFIDThe reader supplies power to the chip and exchanges chip IDs, certification certificates, and updates of passive environmental sensor readings.

NoiseFigure, a technology company in Seattle, Washington, is developing a probe-shaped near-field HF reader to read the ID number and sensor data of the SHIELD chip. Kilopass will provide low-power, one-time programmable memory. The Packaging Research Center of Georgia Institute of Technology will develop cutting and processing methods for the microchip.

Any location in the supply chain can read the RFID tag to confirm the authenticity of the part. Subsystem and system manufacturers are expected to read these tags to confirm the authenticity of parts before manufacturing or delivering to the product manufacturer.

(The chip size is similar to the size of the Lincoln head on the north side of the one-cent Lincoln commemorative coin)

If the chip is removed from the part, it will no longer be usable.

Suko said: “The initial goal of this product is to be used in military products and civilian industries. The ultimate vision is to widely use SHIELD technology in the global integrated electronics industry.”

The Department of Defense mandates that all defense contractors provide traceability in the supply chain. These requirements will make defense contractors the first customers to adopt the SHIELD system. Suko said that commercial products will also use SHIELD technology. SHIELD chips will not only be used in ICs, but also in other circuit boards and components. DARPA’s target price is 1 cent per chip.

The development project is divided into three phases. In the first 18-month period, SHIELD technology will be developed and exhibited on a basic level. Northrop Grumman will develop key functions of test chips and near-field readers and launch SHIELD software.

In the second phase, Northrop Grumman will complete all the functions of the chip and provide 1,000 SHIELD chip products.

In the third and final stage, SHIELD chips will be used in different original equipment manufacturers (OEM) ICs and other products. Suko explained: “This phase will evaluate the effectiveness of the SHIELD system for authenticating electronic parts.” Mass production and deployment will start in 2019.

(Exclusive manuscript of rfid world network, please indicate the source author for reprinting!)

[ad_2]