RFID technology is expected to become a cornerstone of the development trend of smart logistics!

[ad_1]

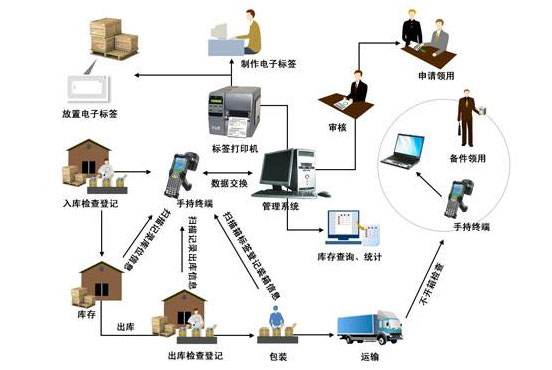

Warehousing management has always played a very important role in the logistics link. As the logistics field has begun to adopt RFID technology, huge logistics products are circulating every day. RFID technology quickly banned traditional technology with its fast speed and good stability. . The development of smart logistics is inseparable from technologies such as the Internet of Things, RFID, and picking, and various technologies are gradually integrated into the logistics industry. RFID technology is expected to become a cornerstone of the development trend of smart logistics!

Although most of them have begun to deploy RFID technology, logistics companies can shorten the operation process, increase the throughput of the distribution center, improve the quality of inventory operations, increase the transparency of supply chain management, and the transmission of information more quickly, accurately, and safely. , But still need to continue to optimize.

Because there are many kinds of goods transported by logistics, generally speaking, conductive liquid substances will have a strong absorption effect on electromagnetic waves, while metal objects or high-density non-metallic materials will have a reflection effect on electromagnetic waves. In logistics applications, especially in daily necessities, luggage sorting, etc., the content of logistics objects is often uncertain, that is to say, the nature of logistics objects is very complex, with solid and possible Conductive liquid, metal objects may also be present.

The shape and size of the object. The shape of the recognized object For regular-shaped objects, the label installation is easier and does not form an obstruction. Need to consider the impact on the RFID recognition effect from the aspects. The size of the recognized object is directly related to the reading distance of the system, and affects the installation method of the reader system. Of course, if the tag is fixedly installed on one side of the reader antenna, the reading effect can be guaranteed to be ideal.

The moving speed of the object. The moving speed of the identified object is related to the time the tag stays in the electromagnetic field, that is, the time for the tag to obtain energy. The longer this time is, the more the internal capacitance of the tag will be charged, the longer the continuous discharge time, and the more stable and reliable the work will be. However, with the gradual improvement of the performance of readers and antennas, too high speed will affect the accuracy of reading results and will be effectively controlled.

Since the basic principle of the RFID system is the coupling and propagation of electromagnetic waves, the performance of the system is very sensitive to the electromagnetic influence of the installation environment. In actual applications, a wire, network cable, etc. in the installation environment may affect the reading performance of the system. In the logistics center, there may be various metallic shelves, which will seriously affect the transmission of RFID electromagnetic waves.

The so-called application level of the RFID system refers to the level to which the RFID tag is applied, whether it is item level, small package level, large package level, pallet level or container level, and so on. Taking cigarettes as an example, the application can be each pack of cigarettes, one piece, or one box, and for warehouse management, it can also be a tray. Different levels of applications will change the size of the identification object, the number of identification objects simultaneously identified, etc., and therefore will also affect the quality of the identification effect.

The shape and size of the label and the installation method will also affect the stability of use. The label has a variety of shapes, including strip, card, cylindrical and all kinds of special-shaped labels. The size and shape of the label need to be determined according to the needs of the specific application system. However, the smaller the label, the worse the reading effect, and the more difficult it is to encapsulate the label. Label installation includes pasting, hanging, embedding, wearing, etc. For larger labels used on trucks, containers, etc., riveting can also be used. The choice of installation method and installation location is also very important for the system.

For the entire RFID system, the RFID electronic tag is a consumable, so the cost of the tag is relatively high. Therefore, the choice of the RFID system must be based on the value of the identified item and the added value that can be created. Take a comprehensive consideration.

RFID has become a certain contributor to the development trend of smart logistics in the application of logistics, and there are still many problems to continue to optimize. The various advantages of RFID technology will play a perfect role. With the acceleration of the technological innovation process of logistics enterprises, the efficiency and transparency of information management have become ideal pursuit goals. Continuously realize effective operation process improvement and increase work efficiency to meet the major construction of logistics informatization, intelligence and modernization in the future.

[ad_2]