Application of RFID personnel location attendance system in Zhaogu No. 1 Mine

[ad_1]

The Zhaogu No. 1 Mine of Henan Coal & Chemical Group Coking Coal Company is located in the east of Jiaozuo Coal Field. Construction started in June 2005 and completed and put into production in May 2009. The construction project of Zhaogu No. 1 Mine is a national key project. In recent years, with the continuous improvement of the country’s requirements for coal mine safety production, as a new modern mine, Zhaogu No. 1 Mine has been committed to the safety management concept of “starting from scratch, striving to zero”, and regards safety production as the most important part of the production in the mining area. The most important thing.

In order to improve the mine safety information automation management level, implement the safety concept of starting from zero and striving for zero! With the primary purpose of mine disaster prevention and improvement of post-disaster rescue efficiency, the mine cooperated with Chongqing MeiAnsen Technology Co., Ltd. in 2009. After underground field survey and research, the KJ237 mine personnel positioning and attendance system was installed and used in the Zhaogu No. 1 mine.

1 System structure

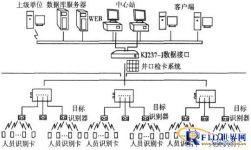

The structure of the KJ237 personnel positioning system is shown in Figure 1. The system adopts a tree structure network, which is divided into three levels: the first level network: ground monitoring center; the second level network: wired data transmission platform; the third level network: wireless information acquisition system. Among them, the ground monitoring center is composed of a monitoring host, system software and other network computers.

(1) The monitoring host is responsible for the management of the entire system equipment and personnel detection data, sub-station real-time data communication, statistical storage, display, query printing, screen editing and other tasks. Equipped with dual machine hot standby function.

(2) The system software can complete functions such as personnel information code collection, identification, processing, display, storage, query and report printing.

(3) Other computers can display part or all of the monitoring screens and data through the group local area network, and can perform remote operations under specific permissions.

Figure 1 KJ237 personnel positioning and attendance system structure

2 Communication method

RS 485 (TCP/IP) mode is used for wired transmission signals between underground positioning substations, and they are uploaded to the ground monitoring center through the data interface (downhole switch). The personnel positioning substation serves as the connection system between the ground monitoring center and the wireless information acquisition system. Under normal conditions, the personnel positioning substation will receive the collected real-time personnel information and upload it in a round-robin manner. When the communication with the ground monitoring center is interrupted, the substation can retain the received data. After normal communication is restored, the substation can upload it to Ground monitoring center to ensure the continuity of downhole information for each person entering the well in time.

3 Implementation principle

The technology used in system positioning is RFID radio frequency identification technology. RFID technology uses wireless radio frequency to carry out non-contact two-way data transmission between the card reader and the identification card to achieve the purpose of target identification and data exchange.

The RFID system consists of two parts: identification card and card reader. The identification card is composed of coupling elements and chips. The card reader reads the internal personnel information of the identification card through the built-in antenna, and transmits the identified personnel information to the underground substation through the cable (optical cable), and reads the information carried by the underground substation. The information of the card device is collected and transmitted to the ground monitoring center, and the monitoring center stores the employee information in the data table in the database through corresponding restriction rules.

4 main functions

(1) Real-time tracking and positioning of underground personnel. This part is mainly used to track and locate the current underground personnel. Through the functions of this part, it is convenient to carry out real-time tracking and management of some special personnel and abnormal personnel in the current underground.

(2) Inquiry of underground employees. This part is used to query various information of underground employees for reference and use by managers. Using this function, managers can easily understand the employees’ downhole activities, stay time, distribution, etc., so as to comprehensively manage downhole personnel.

(3) Staff attendance management. This part is used for the attendance management of underground employees. The system attendance is generated by the employees’ activities in the underground, which avoids some inconvenient management disadvantages of the previous attendance system. Through the functions provided in this part, individual and collective attendance can be inquired in detail in order to understand the specific attendance situation; and various attendance statistics can also be statistically analyzed through the attendance statistics function.

(4) Staff information management. This part is used to manage all kinds of employee information, including basic employee information, management information, attendance information, etc.

5 Installation plan

A total of 7 intrinsically safe substations (1 on the ground) and 39 card readers (3 on the ground) were designed and installed underground this time, covering the underground dispatching room, east and west alleys, underground parking lots, belt lanes, and dedicated return Install large LED display screens with specifications of 1600mm & 1200mm at the entrances and exits of wellheads, waiting rooms, etc. on the air lanes, mining working faces and entrances and exits, pump rooms, chambers, and substations.

In addition, in order to realize the attendance function of downhole personnel, an attendance target recognizer is installed at the position of the auxiliary well head and the bottom of the well. Taking into account the later development, the system has 10 base stations, 20 card readers, 10km transmission cable and 1500 identification cards as spares, which can meet the needs of the later development of the mine.

6 Application effect

After the implementation of the positioning method for all personnel entering the well, the personnel entering the well have entered the real-time monitoring area after receiving the miner’s lamp from the ground. The system can monitor the activity trajectory of all types of personnel at any location in the well. The wellhead large screen and the safety dispatch center are on duty 24 hours a day, keeping track of the underground staff dynamics at any time, and recording in detail for future reference, which truly achieves the good effect of no blind spots in the system signals and no omissions in personnel monitoring, and realizes a modern high-tech system integrating attendance and positioning. The scientific and technological management model has laid a solid foundation for the safe development of the mine.

In the event of an emergency in a mine, rescuers can use the system to quickly grasp the information and location of underground employees, which can shorten underground search and rescue time, improve rescue efficiency, and ensure that the life and property loss of trapped employees is minimized. Has good social and economic benefits.

7 Conclusion

Since the personnel positioning system of Zhaogu No. 1 Mine was put into operation in November 2009, it has been operating stably with good results. After studying the data collection of personnel attendance management, it is believed that the system is currently fully functional, convenient to use and has high application value. The use of the KJ237 system has improved the safety production information management level of Zhaogu No. 1 Mine and laid a solid foundation for the safe development of the mine.

[ad_2]