SAIC GM’s smart manufacturing and smart logistics exploration

[ad_1]

1. The background of intelligent logistics construction

1. Intelligent manufacturing is the direction of transformation

In recent years, the automobile manufacturing industry has faced many challenges such as overcapacity, customer demand for product diversification and individualization, rising raw material and labor costs, and reduced profit margins. Traditional management methods and operating modes have obviously encountered bottlenecks.

The rise of intelligent manufacturing has undoubtedly brought new opportunities for the transformation and development of the automobile manufacturing industry. With the rapid development of the Internet, people’s thinking patterns have undergone subversive changes; at the same time, the development and mature applications of various new technologies will push business intelligence to a new level and make the realization of artificial intelligence possible. These impacts on the auto industry have extended from auto products to the entire auto industry. Many auto companies around the world are actively completing their transformations, and SAIC GM, as a leader in the Chinese auto industry, is no exception.

In fact, in the early days of the company’s establishment, SAIC-GM was based on an advanced technology and high automation rate, and had a complete information system to support efficient business operations. The company has continued to innovate in the development process, continue to introduce advanced production technologies and processes, increase investment in automation, digital, and intelligent equipment, and continue to consolidate its leading advantages in manufacturing. It can be said that 20 years of accumulation has laid a solid foundation for SAIC GM to implement intelligent manufacturing.

SAIC GM’s entire intelligent manufacturing system is composed of intelligent systems, intelligent products, intelligent R&D, intelligent design, intelligent production, intelligent quality, intelligent sales, intelligent services, and intelligent logistics, covering product development, manufacturing processes, and equipment engineering development. , Manufacturing, logistics operation and management, quality control, marketing and after-sales service. SAIC-GM has deployed a global digital and intelligent application practice in each of the above-mentioned business links, and will steadily advance in stages.

2. The time for the development of smart logistics has arrived

As a core part of automobile manufacturing, logistics also faces many pressures. The improvement of logistics efficiency under the traditional model is close to the bottleneck, and breakthroughs need to be sought; market demand and product supply need to be more accurate and faster, and higher requirements are placed on the supply chain and logistics; labor costs are rising, land resources are scarce, and prices continue to increase, etc. Factors have led to a substantial increase in logistics costs; emerging industry companies have unique advantages in Internet resources, and automotive logistics is facing the threat of cross-industry competition. In this context, auto logistics is increasingly embedded with “smart” demands.

In addition, in recent years, the continuous emergence of automation equipment, intelligent robots, and new control technologies, and the continuous development and maturity of advanced technologies such as the Internet of Things, visual recognition, big data analysis, cloud computing, and machine learning, have provided good for the development of intelligent logistics. Opportunity.

For SAIC GM, the intelligent transformation of logistics is the goal of the company to maintain its advantages and continue to advance, and it is also an important part of supporting the smooth advancement of the company’s intelligent manufacturing. On the other hand, SAIC-GM, as the leader of the automotive industry chain, will also coordinate and drive the common development of the automotive upstream and downstream industry chains through the advancement of its smart logistics strategy.

2. Robust digital logistics development plan

The development of SAIC General Intelligent Logistics will focus on the five directions of modularization, automation, digitization, networking, and intelligence. The realization of digitization is regarded as the basis of intelligent transformation. In 2015, based on the company’s smart manufacturing development strategy, SAIC GM formulated a supply chain and logistics digital development plan, and carried out a global digital transformation of traditional business processes throughout the entire logistics process; at the same time, it relied on automated logistics equipment, perception technology, and Internet of Things/Services. , Big data, intelligent optimization algorithms and other advanced technologies, try to intelligently transform some logistics businesses and systems, explore and find breakthrough points in traditional businesses and new profit growth points, and lay a solid foundation for the transformation and upgrading of intelligent logistics.

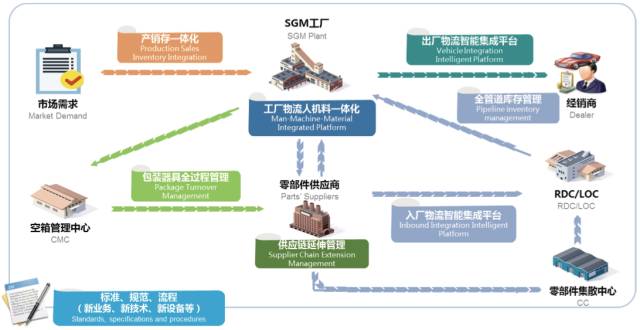

A panoramic view of SAIC GM’s digital strategy

1. Grasp the characteristics of the automotive supply chain and promote the digitalization of logistics

(1) Long business chain, multiple links, and wide scope

SAIC GM’s supply chain and logistics management operations are in charge of the production control and logistics department. Its business covers the entire business chain of production planning, material preparation, inbound logistics, factory logistics, and delivery logistics; including production plan management and parts Planning management, inventory control, supply chain management, material transportation management, warehouse management, bin and rack management, packaging design, vehicle delivery and other business links; the business scope involves almost all departments within the company (marketing, purchasing, finance) , Engineering, manufacturing, quality, etc.), outside the company involves parts suppliers (including domestic and foreign) and logistics service providers (including land, sea, air, etc.).

(2) Large number of systems, poor interconnection and interoperability

Based on the complexity of the supply chain, SAIC-GM’s information system construction and application are also relatively complicated. The specific manifestations are as follows: First, there are many business departments in the company, and there are more than 30 systems involved and applied by each department; Second, the systems of each business department were developed separately in the past, and the interconnection and interoperability were not strong, resulting in different system efficiencies; Third, Each system does not grab data from the same data pool at the same time, causing information asymmetry.

2. Building an interconnected digital information system

In order to achieve an efficient connection between the upstream and downstream of the supply chain, SAIC GM needs to start from two aspects to promote the digital transformation of all links in the traditional business flow: one is to unblock the entire business chain, and the other is to unblock the entire information flow. To this end, SAIC GM has adopted an enterprise architecture method to form an end-to-end overall plan for business architecture, application architecture, data architecture, etc., to form an end-to-end overall plan to ensure that each digital information system conforms to the department Strategy, business and technology development requirements, to achieve interconnection and intercommunication; at the same time, the data modular design is adopted in the IT architecture design to ensure that when the relevant system is changed in the future, only the characteristic modules need to be changed, without any impact on other systems. .

As an example, Ni Bin introduced the overall architecture and layout of the smart factory. The factory uses industrial Ethernet technology to provide high-bandwidth networked access for the underlying production equipment. Sensors, actuators and other equipment at the equipment layer are connected to the system through industrial Ethernet; at the control layer, PLC products are used to achieve integrated control of process and safety equipment, and a large number of PC-based or panel-based HMI products are deployed on-site. Obtain production equipment operating status information and process information, and can remotely control; at the workshop level, MES system is deployed, with functions such as production process monitoring, equipment monitoring, production planning and scheduling, logistics operation management, quality information collection and traceability, etc. , And link up with the enterprise ERP system; at the enterprise level, according to the business chain and functional division of labor, the ERP system and other related systems are deployed to achieve the system function coverage of the entire business chain.

In the future, as the plant continues to invest in the construction of the Internet of Things, more sensors and equipment will be connected to the equipment layer and control layer, and more data will need to be collected and transmitted for processing and analysis; at the workshop layer and enterprise layer, big data analysis will be promoted And visualization tool applications to help identify optimization opportunities in business operations, and use digital modeling and analysis, intelligent algorithms and other technologies to explore advanced applications such as intelligent scheduling, intelligent scheduling, and intelligent optimization; at all levels, it will combine specific project requirements. Carry out the performance upgrade of the communication network and deploy related business applications.

3. Exploration of the construction of intelligent logistics system

According to Ni Bin, based on the consideration of cost control and risk control, the advancement of the construction of SAIC GM’s intelligent logistics system is not concentrated on a certain production base or a certain factory. Instead, it uses global resources to select suitable projects in different locations. The factories will be piloted separately and will be fully promoted in the four factories after success. In the two years since the implementation of the smart logistics strategy, SAIC-GM has conducted separate trials on digital technology and smart logistics equipment, laying a solid foundation for the comprehensive realization of smart logistics transformation and upgrading.

1. Digital technology application and exploration

SAIC GM has continuously introduced digital technology applications in production planning, inbound logistics, factory logistics, supply chain extension management and other links to promote the digital and intelligent transformation of logistics.

(1) Digital scheduling technology

In 2016, SAIC GM applied digital production scheduling technology to the stamping business for the first time in the domestic automotive industry. The production scheduling of the press shop is a typical mathematical model with small batches, multiple boundary conditions, and multiple constraints. At the same time, due to many factors such as long mold change times, multiple times, and uncertain locations, the constraints that are manually considered are limited. The scheduling efficiency is low. SAIC-GM has transformed the traditional manual production scheduling into digital production scheduling, which can greatly shorten the time required for production scheduling and quickly respond to changes in production demand; reduce the area of the material buffer area, increase the utilization rate of the site, and realize lean inventory management; rationally arrange and allocate personnel , Improve the work efficiency of planned staff, equipment utilization and production efficiency, and can reconcile overcapacity, reduce public power, and reduce various logistics operation costs.

After gaining experience in digital production scheduling at Pudong Jinqiao Stamping Plant and further optimizing the algorithm, SAIC-GM will gradually promote the technology to powertrain plants and vehicle assembly plants in 2018, and then fully adopt it in the four factories.

(2) Indoor positioning technology

SAIC-GM applied indoor positioning technology for the first time in the field of automobile manufacturing factory logistics, combined with various advanced sensing technologies such as automated scanning, to realize digital tracking and analysis of people, machines, and materials, optimize feeding paths, improve personnel efficiency, maximize equipment utilization, and lean The inventory in the factory effectively supports the construction of a digital factory.

(3) Intelligent scheduling technology

It is the first time in the industry to try to apply intelligent scheduling algorithms to efficiently match material requirements and logistics resources through global resource scheduling in inbound logistics, factory logistics and other links, and achieve a substantial increase in overall logistics efficiency.

(4) Simulation technology

At present, simulation software is mostly used for factory planning or product development, and the simulation technology for the combined operation of all automation equipment in the entire process is still blank. SAIC-GM is exploring the use of simulation software in the overall planning of the logistics system to simulate bottlenecks in the entire logistics process, predict risks, and simulate more solutions to find the best solution.

(5) Application of narrowband technology in the tracking of bins and racks

SAIC-GM utilizes China Mobile’s narrowband technology and integrates a GPS module. As long as the mobile phone has a signal, it can track and transmit information such as the location and status of the bins and racks, realizing the full life cycle management of the bins and racks. The application of this technology is currently in the exploratory stage.

2. Application and exploration of smart logistics equipment

In the process of building an intelligent logistics system, SAIC GM continued to promote the level of logistics automation around the eight major operational links of factory entry, receiving, warehousing, sorting, online, offline, shipping, and leaving the factory. The main automated logistics systems currently in use are as follows:

(1) Automated three-dimensional library

SAIC GM has piloted different forms of three-dimensional libraries, including shuttles, stackers, etc., in multiple factories at four bases, which are used for the automation of a variety of standardized large-scale components and assemblies, including engines and gearboxes. Storage improves the utilization rate of storage area and the efficiency of logistics operations.

Automated three-dimensional library

Automated three-dimensional libraries are currently less used in the automotive industry, mainly because of the large differences in specifications and sizes of auto parts, making it difficult to achieve high-efficiency applications. However, with the increase in land costs and labor costs, the application of automated three-dimensional libraries has become a trend.

(2) Intelligent new AGC

SAIC GM took the lead in introducing the internationally advanced intelligent new AGC on a pilot basis to complete the automatic delivery of materials online. Different from the traditional magnetic-track navigation AGC, the intelligent AGC can rotate 360 degrees in situ, with almost no turning radius, and there is no need to restrict the dense stacking of components beside the line, which improves the online efficiency.

At present, the new intelligent AGC is widely used in the express logistics industry, but less in the automotive logistics industry. At the same time, SAIC GM also discovered during the AGC application process that because some parts in the auto industry weigh more than one ton in overall packaging, and the current AGC lifting power is limited, it is not capable of automatically launching all parts. SAIC GM is communicating with industry-leading companies such as Siasun, Hikvision, and GeekPlus, hoping to make technological breakthroughs in the future.

(3) Unmanned forklift

SAIC GM has applied laser-navigated unmanned forklifts in Pudong Jinqiao and Wuhan branches to realize automatic storage of materials and unmanned operation of certain parts of the warehouse. Logistics efficiency has been significantly improved. In the future, it will increase investment.

(4) Intelligent picking robot

SAIC GM introduced intelligent picking robots for the first time in the automotive industry to automatically pick sunroof parts, which improved sorting efficiency. In the flexible production site, materials need to be sorted. SAIC GM uses intelligent picking robots to automatically grab the skylights and place them on the material racks, and arrange the order according to the production plan. Finally, the AGC drags the material racks to the edge of the line, realizing the unmanned selection of skylights and on-line.

Skylight intelligent sorting robot

In addition, SAIC GM also uses automation equipment to realize automatic scanning, automatic packaging, and automatic short transfer of whole pallet materials; independent research and development of unmanned trailers, realization of unmanned automatic transfer of materials between plants at the shipping end; Large-scale application to improve the efficiency of the material receiving end; use automatic scanning, vehicle stereo storage, automatic car washing and other technologies to improve the efficiency of vehicle logistics operations; in addition, through the establishment of a hardware control system, the unified management and management of different automation equipment Control, initially realize the operation of unmanned warehouse.

4. Difficulties and solutions

During the advancement of SAIC-GM’s intelligent logistics, many new technologies and new models were tried for the first time in departments, companies and even industries. There were no mature solutions to learn from, and many difficulties and challenges were faced. In response to these technical difficulties, on the one hand, SAIC GM established a corresponding platform organization within the department to integrate various experts from the department to focus on technical difficulties; on the other hand, through strategic supplier collaboration, industry-university-research cooperation and other methods, borrowing Various external resources help to advance the project.

In addition, due to the constraints of corporate resources and human resources, it is impossible for all logistics systems and operating links to promote intelligence together. How to find a balance between technology and cost and find a breakthrough must also be considered in the process of intelligent logistics construction. What SAIC GM is pursuing is lean and intelligent logistics, to achieve the best solution with the lowest cost, and the application of all new technologies and models is to ultimately generate benefits. Therefore, after SAIC GM has made an overall plan for the development of intelligent logistics, it will sort out which businesses in the entire business process have a system, and find the most critical links to try first. For example, inbound logistics and outbound logistics are the most complicated and account for the most logistics costs. Even if an improvement of 1% is achieved, they will bring considerable benefits, so they have become the focus of smart logistics construction. There are also some relatively simple and easy businesses that can be tried first. To put it simply, the steps of the intelligent transformation of logistics are to advance the business that has high returns, high returns and quickly generate benefits; some large-scale and difficult links adopt the concept of “small steps, fast iterations”. Advance.

Finally, it is worth mentioning that there will inevitably be some detours in the process of piloting and verifying new technologies, but SAIC-GM’s management has always held a fault-tolerant attitude towards innovation and allows trial and error, which makes relevant personnel lay down their burdens and try boldly. , So that the improvement project can progress quickly.

5. Value analysis and future prospects

Regarding the value that the construction of the intelligent logistics system brings to SAIC-GM, Ni Bin said that SAIC-GM’s original logistics system has a solid foundation. In the process of building the intelligent logistics system, every small step is a big breakthrough. The current exploration has reached The expected effect. The continuous advancement of SAIC-GM’s intelligent logistics can accurately connect both ends of demand and resources, fully connect key links such as product design, manufacturing execution, and market sales, support rapid and accurate product customization, and flexible production, creating the company’s core competition for intelligent manufacturing force.

Vision of SAIC-GM’s Intelligent Logistics Ecological Map

[ad_2]