High-performance RFID technology helps large oil fields improve the reliability of asset management

[ad_1]

A large oil field in eastern China is facing complex and numerous industrial asset management challenges. With the strengthening of safety measures and the improvement of production efficiency, the manual-led management methods in the past have gradually become incapable of meeting the ever-increasing industry requirements. The safety production standards of the petroleum industry that came into effect in 2013 regulate the safety inspections and information records of oilfield companies in a more stringent manner. In the past, the commonly used barcode identification assets are no longer applicable in such an environment. The oilfield chose Xerafy’s high-strength RFID tags and the oilfield asset management solution developed by Shengli Software to solve the challenge of oilfield outdoor asset management in a one-stop shop.

Background introduction

The current situation of China’s oilfield asset management is facing the same challenges: increasingly strict legal supervision, harsh weather conditions, and highly dangerous equipment assets. The assets on the oilfield site have been exposed to a variety of corrosive chemical reagents under high temperature and high pressure environment for a long time. In recent years, the frequent occurrence of oilfield operation accidents at home and abroad has raised the issue of safety production in refining and chemical enterprises to an unprecedented height. Production shutdowns or production accidents caused by improper asset management will directly affect the safe operation and long-term development of the oilfield. To this end, the State Administration of Work Safety in February 2013 formulated a number of industry standards for safe production in the petroleum industry.

A large oil field in eastern China has shown an urgent need to improve its asset management model, and the corresponding commercial value can be seen from it. Safer and more standardized asset management will ultimately bring about the efficiency of the entire oil field’s production and operation and the improvement of production capacity.

Traditional asset management

The vast majority of domestic oil fields use a combination of bar code, laser marking and manual inspection for asset management and tracking, but these methods are not only poor in reliability, but also time-consuming and labor-intensive, and cannot meet the environmental requirements of asset management in the oil and gas industry.

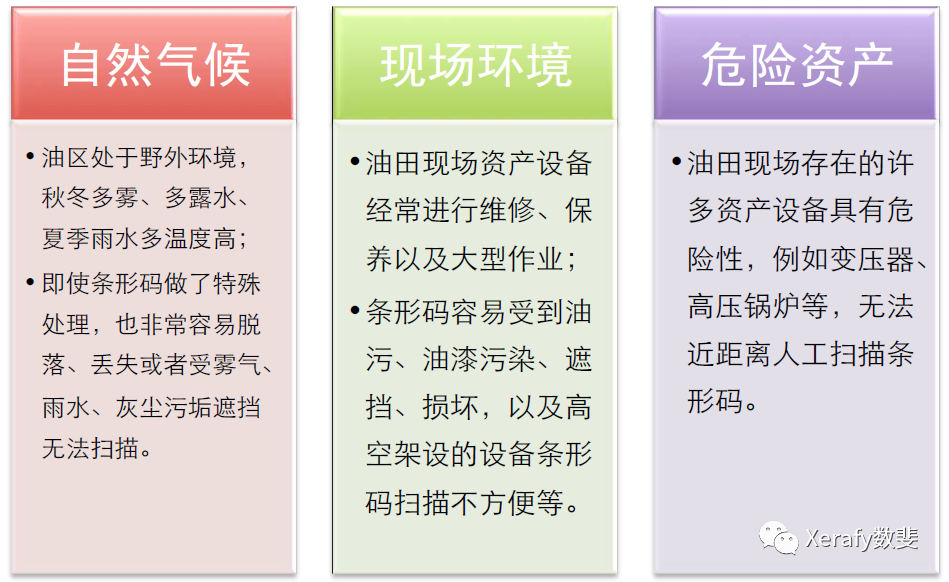

Oilfield asset management is often affected by the following three factors:

Choose RFID technology

In theory, RFID can overcome difficulties such as the environment and asset materials, but users will still find the limitations of RFID when they really start to apply this technology. The oil field tried a variety of RFID application solutions, and finally chose the RFID solution developed by Shandong Shengruan Technology Co., Ltd. Shandong Shengruan Technology Co., Ltd. is a high-tech company engaged in the construction of petroleum information systems. Its customers cover major oil fields and oil and gas companies under PetroChina, Sinopec, and China National Offshore Oil Corporation. Winsoft Technology has passed the national ISO9001-2000 quality management system certification and CMMI3 qualification certification, and has a good cooperative relationship with internationally renowned IT companies such as IBM, HP, Oracle, and Cisco.

The large oilfield plans to use RFID for management of most of its blowout wells, oil pipelines and other related assets within 4 to 5 years. The first assets to deploy RFID tags are portable pole-type transformer equipment used in onshore oil exploration. These equipment will move with changes in the job site. Workers need to maintain and overhaul the transformers on a regular basis. However, because the transformer is a live device at a high place, when using a barcode to read, it also needs to climb close to read it, which is time-consuming and labor-intensive, and safety cannot be guaranteed. Winsoft Technology has selected several types of UHF passive RFID tags on the market. After repeated tests, the Xerafy multifunctional Trak series label Cargo Trak stands out. Cargo Trak is a type that can be used in both metal and non-metal environments. The label has a read-write distance of up to 12 meters and can withstand temperature environments from -40°C to +85°C. The label meets the IP68 environmental rating and is completely resistant to dust, liquids and corrosive substances. Cargo Trak can be permanently installed on the transformer, the staff does not need to climb, as long as the reader is aimed at the tag.

Xerafy has a complete series of labels in the oilfield industry, suitable for different asset classes, environmental needs and installation requirements, including high-strength labels that have passed ATEX certification, labels that can be directly embedded in metal, and other special oilfield application labels.

RFID realizes intelligent asset management

The purpose of this oilfield asset solution jointly developed by Xerafy and Shengruan Technology is to install RFID tags on the transformer and cooperate with the software system to record all important information of the transformer from installation to use, and during service. These information include: transformer activation Time, job site information, service time, asset inventory and maintenance records; asset regular inspection records, relevant responsible person information, etc.

The oilfield has installed tags for more than 30,000 transformers, and each tag has a unique EPC code before leaving the factory. In addition, the tag also uses a laser to artificially visualize the information, which is convenient for the staff to read. The label is fixed on the transformer with special epoxy glue to ensure that it will not fall off due to the harsh outdoor environment. Using a handheld reader, the staff can read asset information in just a few seconds.

RFID technology can help oilfield companies grasp the status of asset use in real time, and regularly maintain, inspect and calibrate assets. Ensuring the normal operation of tools and equipment is extremely important for the oil and gas industry to comply with industry safety guidelines. It greatly improves the safety and convenience of asset managers’ on-site operations, and meets the requirements of oilfield informatization.

The solution achieved:

Automatically record transformer maintenance and inspection information

Better comply with industry safety guidelines

Improve the safety of oilfield asset management

Reducing asset management costs “By using electronic tags to identify physical outdoor assets, the problem of fragile and easy-to-lost barcode marking methods is solved. The safety of field operations is effectively improved.” said Xu Haiting, manager of the Petroleum Technology Development Department of Winsoft Technology. Asset managers can complete the asset inventory task without contacting the outdoor asset equipment of the oil field that is in motion and live. The data obtained is more accurate and timely than before. Through large-scale tag deployment, it is believed that the cost of asset management in the oil field will be increased. Decrease year by year.”

The Xerafy Cargo Trak label has been replaced by the upgraded Cargo Trak II. The upgraded Cargo Trak II is more robust and durable.

[ad_2]