RFID implements full-cycle and full-process supervision of oilfield materials

[ad_1]

With the continuous expansion of the actual logistics transfer scale of the oilfield and the increase in the types and quantities of materials, the supply management of materials has become more complicated and difficult. In recent years, the management of oilfield materials has become more subdivided. The specialized division of labor and process operation of material supply has promoted the benign operation of the internal supply chain from demand planning to material distribution to the production site. Petroleum companies have established a world-class international level through the four managements of “standardized design, modularized construction, standardized procurement, and informatization improvement”. The Internet of Things technology plays a very important role in material supply management. The use of RFID to manage the whole life cycle of oilfield materials and the dynamic management of the whole process is the need to strengthen the standardization of material system logistics operations, and make oilfield material management informatization very large. The promotion.

Oilfield warehousing and distribution standardization systems are gradually being improved. Oilfield material supply management information system, barcode, GPS and other technologies have been partially applied. The application level of Internet of Things technology in material procurement and supply is gradually improved to realize the entire process and life cycle of oilfield materials. The basic conditions have been established for management.

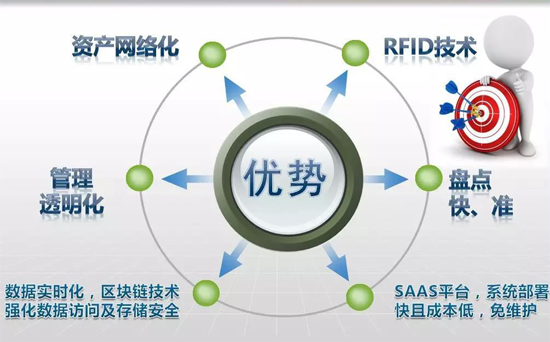

The oilfield material system needs to take material life cycle management as the core, with the application of Internet of Things technology as the starting point, and build a powerful information platform to solve current problems and realize its own structural optimization. The integration of oilfield material management. The construction of the platform integrates oilfield materials from demand to consumption, recovery, and asset management into a unified management category, and realizes cross-department, cross-industry, and cross-regional applications, which are mainly reflected in the following points:

Cross-department: Material management involves both the material demander and the procurement supplier, as well as the asset management department, supervision and inspection, production management, technical supervision and other departments. Through the establishment of an integrated platform for the oilfield material management system, the all-round inheritance and sharing of material supply information can be realized.

Cross-industry: The industries involved in the project cover all industries in the entire oilfield, including drilling, logging, logging, and exploration, as well as oil production, operations, and logistics support. The implementation of the project will eventually achieve full coverage of the management of materials required by various industries in the oil field.

Cross-regional: Project design is based on the flow of materials. All oilfield integrated purchases only need to enter the management system, whether it is the old eastern area, the new western area, or even the overseas market, will be integrated into the unified management to realize where the supply of materials is, the management of materials and assets is tracked.

Realize the full-cycle and full-process management of oilfield materials. The platform design starts from the production unit’s request for materials and forms a demand plan, and the material supply department needs to balance, plan formation, bidding, procurement, warehousing, and distribution, until each cost center completes consumption. The materials that form assets enter the asset management process until they are scrapped, and the recyclable materials enter the recycling process for reuse. Realize the whole life cycle management of oilfield materials through whole process management.

The full life cycle management of oilfield materials requires the support of a powerful information system. Through the construction of a multi-level, real-time, visual, and standardized comprehensive material management system for the entire oilfield, business collaboration, information integration, and process visualization of oilfield material management and asset management are realized. . Analyzing the main functions covered by the life cycle management of oilfield materials, it is necessary to build 4 subsystems to support the realization of these core business functions: material supply management system; material electronic label application system; material supply GPS-GIS system; material supply video monitoring system .

RFID asset management system functions:

1. Obtain all kinds of information about oilfield assets by scanning tags with handheld devices. Because the RFID handheld device can read many tags instantly, no single scan is required when reading material information, and it can complete the rapid batch storage and batch delivery of materials.

2. The information written on the tag can be encrypted and managed by rights. People without corresponding rights and readers without corresponding decryption equipment cannot read the information in the tag to avoid the theft of material information.

3. Before the materials are put into the warehouse, record the storage location of the materials to be deposited in the RFID tag, and record the information of the storage location of the goods in the label, which can easily complete the active shelf, fast positioning and search of the materials, so that the warehouse management can complete the mechanical initiative. Modernization, informationization and precision.

4. The system automatically counts the inventory and generates the in-out report based on the amount of materials in and out of the warehouse read by the antenna at the entrance and exit. While reading the data, it can actively calculate the information of the materials, so as to complete the active inventory function of the materials, and upload the warehousing and inventory information to the higher authorities in real time.

5. When inventorying and distributing oilfield materials, handheld devices can be used to directly scan and read material information, and the information can be read in batches without unpacking. The accuracy is high, and there are fewer physical objects for manual operations, saving Manpower and material resources.

RFID oilfield material system management

(1) Comprehensiveness

The system effectively manages and controls all management links, and completely solves the problems of management disconnection and difficulty in reconciliation between different departments.

(2) Tightness

The system is equipped with comprehensive and standard database security management measures, which makes the database more secure and reliable, and eliminates the non-standard operation of arbitrarily modifying the database.

(3) Real-time

The entire life cycle of each fixed asset from acquisition and inspection to disposal is monitored and managed, and management activities are recorded in real time to reflect the status of each fixed asset.

(4) High efficiency

Make full use of advanced technical means, such as asset RFID tags, networks, barcode management, remote protection, etc., to intelligently process the software, which is simple and easy to use, and improves work efficiency.

The construction of Shengli Oilfield’s life cycle management platform based on the Internet of Things technology needs to be carried out gradually over a long period of time, step by step, and orderly. Based on the logistics management system, label application system, GPS management system, and video monitoring system, the basic framework of platform operation is established, and the operation is gradually standardized. Finally, through the application and deepening of the platform, the overall material management level of the oilfield is continuously improved.

[ad_2]