DHL Global Freight (China) Co., Ltd. Smart Warehouse Case

[ad_1]

【Customer Profile】

DHL’s business covers 220 countries and regions around the world, and it is the most internationalized company in the world. With more than 315,000 employees worldwide, we can almost provide perfect solutions for various logistics needs.

【system introduction】

Jiukun Information provides an overall solution for DHL’s intelligent warehouse management application based on RFID technology. The solution involves three parts: a logistics system platform, handheld data collection and printing equipment, and a wireless network communication solution.

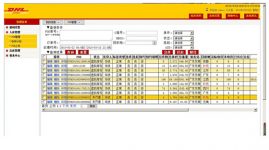

The first phase of the system mainly realized DHL’s outsourced transportation vehicle management, GR receiving of goods, RFID label printing, goods warehousing, inventory, query management, warehouse out and the use of RFID four-channel readers to realize batch shipment management and outbound Realize the combination with video surveillance system and electronic billboard technology to realize error-proof processing, abnormal phenomenon sound and light alarm processing.

The second phase of the system mainly realized the logistics and transportation management from DHL’s cargo center warehouse to the regional warehouse, and the management of regional outbound and inbound.

The system realizes the real-time data interaction with the customer order system and the internal ERP of the group company.

【value of customer】

1. Customized demand: Provides a set of WMS system tailored for Huawei projects;

2. Packing management: Scan the incoming cargo box number, print the sticker immediately, complete the GR receipt after scanning, and can directly allocate the storage space on the PDA side; when leaving the warehouse, according to the volume of the vehicle, the TO can be flexibly increased or decreased through the PDA goods.

3. Real-time management: The barcode scanning data of in and out of the warehouse will update the physical inventory in real time through wireless WIFI, so as to realize the accurate management of the goods in and out of the warehouse and the inventory.

4. Inventory management: the inventory task is sent to the PDA via the WIFI network. When the blind disk and full scan tasks are completed, the database can output the inventory report.

5. Warehouse level management: When the warehouse out of the central warehouse is completed, the TO data will be immediately transferred to the receiving database of the corresponding destination station. The destination station can predict the upcoming arrival information in advance and arrange its own appointment dispatch reasonably Tasks to realize active level adjustment of warehouse locations.

6. Whole-process visual management: After allocating warehouses and dispatching goods to complete out-of-warehouse scanning, the system can update the POD inventory status and realize the entire visual management of the supply chain.

【Customer case】

Complete actual business operations through RFID handheld terminals:

Actual application site:

Ongoing warehousing business:

Ready to be shipped out:

[ad_2]