RFID weighing management application example

[ad_1]

Preface

Power plants, coal yards, garbage dumps and other units have a large number of material transportation vehicles entering and exiting every day, requiring procedures such as parking, registration, and weighing. The data is manually entered into the computer by the operator, which is not only time-consuming, but also has a large error rate. It is also easy to breed man-made fraud and cause a lot of economic losses to the enterprise. The RFID weighing tag is placed on the car, and the relevant data is read by the reader to correspond to the car, which can provide great convenience for the staff.

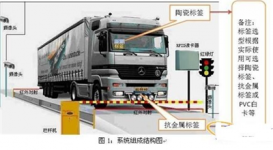

1. System composition

The system includes readers, antennas, tag cards, electronic truck scales, host computers, signal lights (red and green), automatic barriers, ground sensing coils, infrared meters and supporting management software.

Second, the work process

1. The green signal light is on, and the weighing vehicle enters the lane. After the vehicle enters the lane, the red signal light is on, and the next vehicle is prohibited from entering the lane.

2. The vehicle passes through the entrance induction coil to generate an induction signal. After the reader reads the card, the card information is uploaded to the host database and the vehicle information is retrieved at the same time.

3. The vehicle is weighed on a scale, and the display screen displays the weight information of the weighing, and at the same time captures the image information.

4. After the weighing is completed, when the vehicle weighs down and passes the ground induction coil, the barrier is lifted and released.

5. After the vehicle is released, the green light will be on at the same time when the gate is off, allowing the next vehicle to enter.

(According to the actual situation, after identifying the vehicle number information, the automatic barrier gate lifts the gate, the vehicle is weighed, and the automatic barrier gate is closed to prevent the next vehicle from being weighed) (see the picture above)

3. System advantages

1. The vehicle number recognition accuracy can reach 99.99%, which is suitable for various harsh environment applications such as wind, snow, rain, and fog;

2. The data in the label is highly confidential, and the electronic label (electronic license plate) cannot be forged or copied, which fundamentally eliminates the phenomenon of copying, forgery, and cheating;

3. The vehicle electronic tag adopts passive technology, which has a long service life and no maintenance;

4. The automatic collection speed is fast, which can realize fast weighing, improve the efficiency of weighing, and avoid the phenomenon of queuing overbalance;

5. Plug the loopholes of human operation. Due to the method of automatically reading data, all over-balanced vehicles are automatically counted by the computer, eliminating manual intervention, automatically recording data, and automatically verifying and releasing;

6. Long-distance dynamic recognition, the recognition distance is adjustable within 5-25M.

Fourth, the actual scene

Five, product introduction

RFID reader: JT-8290 series (enumerate the parameters in this series for explanation), JT-8288 series, JT8280 series

|

Model Description: |

|

|

JT-8290A |

able to provideRS485communication |

|

JT-8290B |

able to provideRJ45(Network port)communication |

|

JT-8290W |

able to provideWIFIcommunication |

|

Performance parameters: |

|

|

RF power |

0dBm~30dBm(Software adjustable) |

|

Reading distance |

Stable reading:25m(Related to labels and environment) |

|

Industrial lightning protection |

6000VHigh voltage lightning protection |

|

Low temperature protection |

In Northeast, Northwest and other extremely cold regions, add low temperature treatment |

|

testing software |

Provide automatic card writing and readingDEMOSoftware, convenient for customers to issue and write cards |

|

Development kit |

supplySDKDevelopment kit,and provideC#,VC,VB,Java,DelphiDevelopment routine |

|

Connectivity: |

|

|

power supply |

110~240V/50~60Hz |

|

adapter |

12V/3A |

|

Data interface |

haveWiegand263442,RS232,RS485Data interface |

|

Input and output interface |

1Trigger input and2Relay output (customized) |

|

RFIDstandard: |

|

|

working frequency |

902~928 MHz(Center frequency915MHz)Frequency standards of other countries and regions can be customized |

|

Antenna gain |

12dBi(Linear polarization) |

|

supporting agreement |

ISO18000-6C(EPC C1 GEN2)orISO-18000-6B |

|

Applicable electronic tags |

UHFFrequency bandEPC global Class 1 Gen2Standard labels, such as:Alien,IMPINJ,Ti,Philips,UPM,Avery DennisonWaitGen2Label |

|

Physical parameters: |

|

|

Product Size |

450x450x50mm |

|

weight |

5KG |

|

Material |

ABS |

|

Protection level |

IP54 |

|

Environmental parameters: |

|

|

Operating temperature |

-20°C~+65°C |

|

storage temperature |

-45°C~+95°C |

RFID tags: RFID tamper-proof tags, RFID ceramic tags, RFID license plate tags.

Tamper-evident label

Product model: JT-306A/B

JT-306A: Waterproof JT-306B: Not waterproof

Material: paper, 3M adhesive

Size: (length) 110 × (width) 45 × (thickness) 0.5MM

Chip: Alien/higgs3

Support protocol: ISO 18000-6C, EPC Class1 Gen2

Storage capacity: 64 Byte

Applicable carrier frequency: 860~960MHz

Working mode: passive

Others: the surface can be color printed

Ceramic label

Product model: JT-315

Size: (length) 89×(width) 57×(thickness) 3.5±0.2MM

Material: ceramic sheet + ABS shell

Chip: Alien/higgs3

Support protocol: ISO 18000-6C, EPC Class1 Gen2

Storage capacity: 64 Byte

Applicable carrier frequency: 860~960MHz

Working mode: passive

Application: vehicle management and other fields

The automobile intelligent weighing system combines RFID radio frequency identification technology, electronic truck scale technology, communication technology, automatic control technology, database technology and computer network technology, and automatically records the license plate number, weight information, time information, etc. of vehicles equipped with electronic tags. And written into the host database, can effectively eliminate human error, prevent over-balance blockage, cheating and other situations.

[ad_2]