Telink Introduces RFID Management Vaccine “Cold Chain”

[ad_1]

Hainan Tai Ling Biological Products Co., Ltd., a subsidiary of Tai Ling Pharmaceutical Group, is responsible for the distribution and cold chain distribution services of vaccine products from some world-renowned manufacturers in China. Vaccines are particularly sensitive to temperature and can only “live” in a suitable temperature range. This requires that the vaccine must be kept in a relatively constant temperature range during the entire process of circulation, whether it is in, out of the warehouse, or during transportation, to ensure that the vaccine price and efficacy are not affected by temperature changes. Since 2003, Telink Group has established a complete set of vaccine cold chain management system. In the construction of the vaccine cold chain, despite the continuous automatic temperature monitoring of the cold storage and the temperature record of the cold chain transportation, the operators of the Tai Ling cold chain still face a seemingly simple but difficult problem, that is, how to adjust the temperature of the vaccine cold chain. The monitoring becomes real-time monitoring throughout the entire process.

NEC helps cold chain

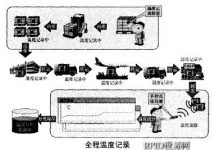

Now, Telink has begun to equip NEC’s advanced information management system, namely the radio frequency identification (RFID) cold chain temperature monitoring system. On the surface, Telink’s cold chain system process does not seem to be any different from before. However, if you observe carefully, you will find that there is an extra square label RFID temperature tag on the vaccine box. Not only is it equipped with an ultra-thin button battery, it can be used continuously for more than three years; it is also equipped with an RFID chip and temperature. sensor. The temperature information collected by the temperature sensor at all times can not only be stored in the RFID chip in real time, but can also be transmitted through the RFID read-write antenna. All information is obtained and transmitted without contact, only an RFID read-write antenna is installed on the warehouse door. When a forklift full of boxes passes through the door, all the cargo information in the boxes (including real-time temperature information) is entered and displayed in Telink’s computer system.

When stored in the warehouse, the box containing the vaccine is always “cared for” —RFID will transmit the real-time temperature information to the information system developed by NEC for Telink, even if the personnel at the headquarters are sitting The office can also know the real-time temperature of the vaccine.

At the same time, the RFID cold chain temperature monitoring system well covers the entire refrigerated truck transportation system. On the top of each transport vehicle, an advanced GPRS wireless transmission system is installed. During the whole process of temperature recording of the vehicle, the RFID temperature tag on the packaging box is not only still faithfully recording the temperature changes of the vaccine, but also real-time transmission of these temperature data to Telink’s cold chain information management system through the GPRS network. Once the temperature is abnormal, the information system will automatically alarm, and the driver can take immediate measures to avoid the risk of cold chain caused by human negligence.

With the help of NEC, the “real-time cold chain management system” was established. The guarantee of cold chain quality needs to be based on a strict quality management system, high-quality cold chain hardware facilities and a high-quality operation team. Here, the RFID system has become an important means of cold chain quality monitoring. Through a better cold chain temperature monitoring system, it can help Telink identify the problems in the cold chain operation more quickly, and promote the continuous improvement of the cold chain operation of the operation department.

From cold chain to dynamic service chain

In the past, whether hospitals or pharmaceutical retail companies, they were more or less worried about the quality of vaccines provided by Tai Ling, and worried that the vaccine would deteriorate due to temperature changes. With NEC’s real-time cold chain management system, they don’t have to worry about it. In addition, Telink can help customers improve the vaccine supply chain. In the future, Tai Ling people with wireless PDAs will be able to visit their homes and inquire about the number of vaccines ordered, their current location, historical temperature data and other information on the spot, all of which are real-time. Of course, customers can also check the real-time information online.

NEC plans to extend this “dynamic service chain” system to all industrial systems that have special requirements for temperature.

[ad_2]