Hongyu Technology Tobacco Industry RFID Application Program

[ad_1]

1.Project background and tasks

In order to realize the efficient operation of commercial arrival scanning and code printing, tobacco business companies must also change the current existing logistics and warehousing model as little as possible. When using pallets as carriers for multiple cigarettes, RFID pallet identification associations are used. The way of cigarette information enables the cigarette barcode information collection system to collect relevant information simply and quickly, and it is necessary to consider that the application of RFID can be organically combined with the company’s existing warehouse system (such as warehouse electronic map system).

This project is aimed at the actual needs of commercial companies for commercial delivery scanning and barcode-to-bar. Combining RFID’s application features such as non-contact, large storage capacity, and fast reading speed, it combines barcode-to-bar three-scan RFID applications for commercial companies. Designed.

2.The general idea of the project

The main purpose is to use the background database to associate the electronic tag with the cigarette information on the tray where the electronic tag is attached.

Apply large-capacity electronic tags to make the relevant information between the electronic tags and the barcode information of the cigarettes. Corresponding to the electronic label and the cigarette information on the tray, the barcode information of the entire tray of cigarettes can be obtained by collecting the data of the electronic label.

Commercial enterprises collect the barcode information of each package of cigarettes when the cigarettes arrive commercially to realize commercial arrival scanning. At the same time, the collected cigarette barcode information and the electronic label representing the pallet identification are built into stacking information, and this stacking information After being compressed and encrypted, it is stored in the data area of the electronic tag of the RFID application. The ID number of the electronic tag on the tray is associated with the barcode information of the cigarette placed on it, and then the cigarette and the tray are as a whole in an associated form Store and circulate inside the enterprise; if the cigarettes on the pallet are changed during the storage and circulation of the enterprise, the stacking information of the electronic label and the barcode information of the cigarettes on the pallet in the electronic label data area needs to be updated to ensure the stacking information Real-time accuracy; in the barcode-to-bar application, the barcode information of the unpacked cigarettes needs to be collected. At this time, the electronic label representing the tray identification can be scanned, and the stacking information of the cigarette and the cigarette barcode in the electronic label data area , Collect the barcode information of all cigarettes in the entire tray simply and quickly.

Combine the stack information of the electronic label and cigarette barcode information with the corresponding warehouse management system (such as warehouse electronic map system, digital warehouse management system), so that the warehouse can be managed to the area (location), to the pallet, and to the cigarette. And so on, to provide the inventory efficiency of the cargo space, and effectively reduce the error of the cargo inventory.

3.Design

3.1 Application of electronic tags to store associated information

If a commercial company uses pallets to stack cigarettes, the current application of commercial arrival scanning and coding to barcodes involves the application of RFID in the following three links:

3.1.1 Arrival of 1 cigarette

After the cigarettes arrive, the workflow is as follows:

Detailed operation process:

1. Open the receipt of delivery;

2. Start up documents and allocate equipment;

3. Use a fixed scanner or a handheld scanner to collect the barcode information of commercial delivered cigarettes. The barcode information is also transmitted to the stack information generation software. The barcode information is carried out in different queues according to the brand in the stack information generation software database. Queuing (the system also supports the user to set the barcode to be queued in the scanning order without distinguishing the brand).

4. Manual pallet stacking of cigarettes with scanned barcodes. The collection and stacking operations of cigarette barcodes must be carried out in strict accordance with the inherent sequence.

5. After a certain pallet is stacked, it is transported to the designated location, and any piece of cigarettes in the pallet is scanned manually with a handheld barcode scanning device. The corresponding barcode data is fed back to the stacking information generation software, and the stacking information generation software starts from Find the corresponding whole pallet barcode information in the scanned cigarette barcode queue, read and write the electronic tags in the pallet through the buried fixed RFID equipment, establish the electronic label and the stack information of the whole pallet cigarette barcode information, and save this The stack information is saved in the electronic label data area, and the association operation between the electronic label and the cigarette bar code information is completed, which marks the beginning of the life cycle of the stack information. (Or use the vehicle-mounted RFID device, you can use a similar method to complete the association operation between the electronic label and the cigarette barcode information when the forklift forks the pallet.)

6. The stack information generation software transmits the cigarette barcode information successfully written into the electronic label to the commercial arrival scanning software to fulfill the business requirements of the commercial arrival.

7. After completing the associated operations, the forklift transports the pallets to the warehouse area.

8. After scanning the confirmation document.

For imported cigarettes and confiscated cigarettes without one-dimensional barcodes, the barcode information of cigarettes cannot be collected through barcode scanning equipment. In order to use electronic tags to associate cigarette information with the entire pallet, it is necessary to artificially define imports in the system Special codes for cigarettes and confiscated cigarettes, manually input the origin, brand, quantity and other information of imported cigarettes and confiscated cigarettes when palletizing, the system automatically generates a defined and specified number of cigarette barcodes, using the barcodes and electronic labels generated by the system Build stack information. In actual operation, it should be required that imported cigarettes and confiscated cigarettes cannot be mixed in the same tray, and cigarettes of different properties must be stacked separately to facilitate management.

When the arrival volume is too large and the fixed RFID system fails, the mobile RFID device can be used as a backup method to complete the association operation between the electronic label and the cigarette barcode information. The operation method is similar to that of a fixed RFID device.

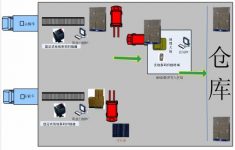

The specific flow chart is as follows:

figure 1

In order to generate palletizing data after palletizing, some equipment needs to be deployed:

Place a 3-color warning light in an appropriate position to indicate whether the writing of data is successful. If the RFID writing is successful, the alarm device will remind the worker to use a forklift to transport the stack of cigarettes into the warehouse; if the RFID writing fails, the alarm device will remind the worker to find the reason, or use the RFID mobile device to rewrite.

3.1.2 Cigarette storage

If the pallet with pallet information is changed in the enterprise’s internal storage and circulation, the new pallet information needs to be updated to the data area of the electronic label to ensure the real-time accuracy of the pallet information.

Detailed operation process:

1. For the pallet with cigarette changes, first use the mobile RFID reader device to scan the electronic tag on the pallet, and the stack information update software deployed on the mobile RFID device obtains the relevant electronic tag by analyzing the data in the electronic tag data area Barcode information of all cigarettes linked together.

2. Then use the one-dimensional barcode scanning equipment to collect and adjust the barcode information of the cigarettes (the cigarettes removed from the pallet and the cigarettes newly placed in the pallet), and the stack information update software automatically generates a new stack according to the original stack information. information.

3. Save the new pallet information to the data area of the electronic tag through the mobile RFID read-write device to complete the pallet information update operation.

See Figure 2 for the update flow chart of Duo information.

figure 2

3.1.3 For cigarettes

When creating and updating the stacking information of the electronic label and the cigarette bar code, it is necessary to compress and encrypt the stacking information of the electronic label and the cigarette bar code, and write the compressed and encrypted data into the data storage of the electronic label through the RFID reading and writing device. Area. When using the stack information of the electronic tag and the cigarette bar code, you need to use the RFID read-write device to read the compressed and encrypted data from the data area of the electronic tag to decrypt and decompress it. After the stack information is used, the stack information needs to be destroyed. Just clear the data area of the electronic label.

According to the customer’s demand information, code to the conditional cigarette scanning software to obtain the requisition information and generate the requisition receipt. After the operator receives the cigarettes, the information of the cigarettes to be sorted needs to be collected before sorting. The electronic label scanning method of the whole pallet is added for the situation of receiving according to the pallet.

Add a set of RFID reading and writing equipment to complete the scanning method of scanning by stack when receiving the whole pallet.

Detailed operation process:

1. Receipt of receipts;

2. Start the receipt and allocate equipment;

3. For cigarettes that are received one by one, one-dimensional barcode collection equipment can be used to collect the barcode of each cigarette according to the receipt.

4. For the cigarettes received by the whole tray, the whole tray of cigarettes needs to be transported to the designated location, and the code is printed to the conditional cigarette scanning software. The buried fixed RFID system is used to scan the electronic tag to obtain the ID number of the electronic tag, and then analyze the electronic The data in the label data area obtains the barcode information of all cigarettes associated with it, which is equivalent to scanning the entire pallet of cigarette information at one time. In this way, the entire pallet of cigarettes coded to the barcode can be scanned for the entire pallet. (Or use the vehicle-mounted RFID device, you can use a similar method to scan the electronic tag when the forklift picks up the pallet.)

5. At the same time, the software needs to clear the stack information in the electronic label data area, which marks the end of the life cycle of the stack information.

6. Scanning completed confirmation documents;

7. The scanned cigarettes are waiting for sorting.

In the event of excessive usage and failure of the fixed RFID system, a mobile RFID device can be used as a backup method to complete the scanning operation of the electronic tag. The operation method is similar to that of a fixed RFID device.

The flow chart of analyzing stack information is shown in Figure 3:

image 3

4.Implementation of the project

4.1 System composition

4.1.1 Software system

Commercial arrival scanning software

Pallet information generation software

Duo information update software

Code to condition smoke scanning software

database system

4.1.2 Hardware system

RFID antenna

RFID tags

RFID reader

electronic label

Wireless AP

One-dimensional barcode scanner

4.2 Hardware implementation

We will refer to the on-site environment and choose different implementation methods as needed. We have three main methods here:

4.2.1 Buried method

4.2.2 Side placement

4.2.3 Mobile trolley

4.3 Installation location

Our equipment is mainly used to achieve the three-scan work, so this determines the installation location of the equipment. First is the entrance of the warehouse. A set of equipment needs to be installed to realize the inbound scanning; the second is the exit of the warehouse, which needs to be installed. A set of equipment is used to realize outbound scanning; finally, a set of mobile equipment is needed inside the warehouse for adjustment, and the mobile equipment can also be used as a backup (for example, when the warehousing equipment is broken during storage, don’t worry about us You can completely push the mobile device over and use it).

4.4 Matters needing attention

4.4.1 Installation position of the label

Here we mainly look at the specifications and materials of the pallet. The specific pallet shape (size, material, stacking quantity, etc.) will have different requirements for the signal and storage capacity of the electronic label. Therefore, the actual plan for a specific enterprise is required. Consider the shape of the tray.

4.4.2 Wiring requirements

The digging solution for buried antennas provided by RFID equipment manufacturers. The cables between the reader and the antenna, and the signal lines between the reader and the alarm light are all run through the wire trough and steel pipe. The steel pipe is used as the external protective casing, and the specific size and specifications are determined according to the needs.

4.4.3 Power supply preparation

The 220V mains power is connected to the position of the reader to supply power to the reader and alarm lights.

4.4.4 Network preparation

A reader needs to allocate an IP address, prepare a network cable, and connect the reader to the network so that it can communicate with the scanning PC normally.

[ad_2]