Application of Intelligent Inspection Management System in Tangshan Thermal Power Company

[ad_1]

1. Project Significance

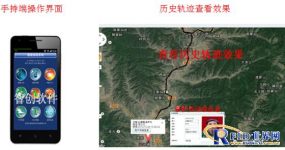

The “Smartphone GPS Heating Pipe Network Inspection Management System” developed by Shijiazhuang Zhichuang Software Technology Co., Ltd. mainly solves the problems of insufficient traditional manual inspection, missing inspection points, incomplete and inaccurate data preservation, data loss and omission. Ensure that the inspection and management of thermal facilities and pipe networks are in place, and the operation status of equipment can be discovered in advance, maintenance and replacement can be arranged in advance, and major accidents can be avoided. The hidden dangers of failure of the heating pipe network and other equipment can be eliminated in time, to avoid leakage and accidents, and to ensure the safe operation of the heating pipe network and heat exchange stations.

2. Basic functions of the inspection device

User authentication

Automatically receive inspection tasks and related data

Normal inspection can be performed when there is no signal, and inspection data will not be lost

Determine your geographic location

Collect equipment operation data and defects by means of text description, photography and video recording

GIS information collection

Automatically record the inspection process (inspection time, personnel, trajectory)

Automatically upload inspection data

emergency alarm

View Company Notice Announcements

Voice prompts

auto update

3. Application

It mainly conducts patrol inspection of the heating pipe network in Tangshan urban area. The management center can plan the inspection lines, formulate inspection plans, and assign inspection tasks, including the location of inspection points, inspection lines, inspection time, inspection times, etc. The GPS inspection device automatically obtains inspection tasks.During the inspection process, each inspector holds oneGPSThe inspection device performs inspections on time according to the inspection tasks assigned by the management center. It can complete simple inspection work without task operation, and the inspection data is automatically uploaded to the management center in real time. When discovering hidden dangers or failures in the pipeline network, the on-site situation can be reported to the management center in a timely manner through text description, photos, videos, etc., so that the management center can deal with it in time to reduce the occurrence of accidents. In case of emergency, you can call the police with one key, and directly report the current accurate location and information to the management center. The management center automatically generates various assessment schedules and summary tables, and the inspection data is permanently stored, providing a real and effective management platform for the inspection work.

Fourth, solve the problem

1. Real-time positioning and supervision of inspection personnel to achieve the purpose of centralized management;

2. The inspection situation is collected on site, and the inspection data is uploaded in real time;

3. Information management of inspection personnel;

4. The inspection data is more real, and the inspection data is effectively saved and managed;

5. The operation of the inspection device interface is simple and convenient, which is suitable for ordinary inspection personnel.

[ad_2]