Application of UHF sensor tag using radio frequency energy harvesting technology in cargo tracking

[ad_1]

Powercast has teamed up with Vanguard ID to develop a UHF tag that harvests energy from the interrogator to power the built-in sensor and transmits the sensory data to a remote 25 feet (7.62 meters) away.Reader.

Vanguard ID is selling a new EPC Gen2 UHF RFID sensor tag for harsh environments. The tag, which was developed by Vanguard ID and wireless energy harvesting company Powercast, has a built-in data display to see data updates.

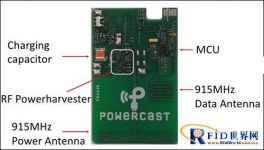

The high-performance tag uses RF energy harvesting technology, which includes a microcontroller and NXP Ucode I²C passive RFID chip.

The RFID inlay includes an RFID chip, a sensor, a microcontroller, and an energy harvesting circuit connected to the chip, the latter provided by Powercast. The inlays are packaged with micro-foam as well as layers of polyester that are resistant to ingress of other liquids such as water resistance, as well as to withstand very high/low environmental impacts.

The built-in sensors of the label are available in temperature, vibration, humidity, inclination and other types, and can be “customized” according to customer requirements.

The tag uses NXP Ucode I²C RFID chip and Powercast RF energy harvesting circuit. The energy is harvested from the interrogator by employing radio frequency energy harvesting technology for the operation of the tag’s built-in microcontroller and sensors. The microcontroller forwards the data to the RFID chip through the chip’s I²C interface, and the chip then sends the data to the reader through the EPC Gen 2 UHF RFID air interface protocol.

This high-performance RFID tag does not require a motherboard battery. There is currently no shortage of common passive UHF tags, however low-energy tags are usually limited by power. Active tags are also unaffordable for most applications, such as in cold chain logistics. Furthermore, most labels cannot withstand extremely low temperatures. Compared with active tags, RF energy acquisition technology provides energy in a low-cost way, and the low temperature environment has less impact on it, and the energy provided is 10 times that of ordinary tag batteries.

This high-performance tag is mainly used to track the sensor data of the environment in which the goods are located to ensure that the environmental data is within the appropriate range. For example, perishable products are usually packaged in dry ice containers, and high-performance UHF tags are placed in or outside the container; the radio frequency signal of the reader provides energy for the tag work, and the relevant data is stored in the company database; users pass the reader through the reader. The display sees relevant environmental data; if the temperature is outside the acceptable range, the system will sound an alarm.

The interrogator simply reads the tag’s user record and does not require special software to read sensory data.

In another application case, high-performance tags are used on factory machinery. Use the label to measure the vibration data of the machine, monitor the operation of the machine, and prevent the machine from suddenly crashing, so as to reduce the loss caused by it.

Retailers are interested in high-performance labels with electronic paper displays. The screen can display 28 letters or diagrams, and its size or other specifications are made according to the user’s requirements. The labels can be placed on storage shelves to display information such as product data and prices. Display data changes according to RFID read conditions.

The maximum distance of UHF tag signal transmission is 25 inches, and its energy is derived from radio frequency energy harvesting technology. Vanguard ID also offers a high frequency 13.56 MHz RFID chip in place of the Ucode I²C chip. Vanguard ID currently offers high performance labels in credit card size, with other styles available upon customer request. Currently, at least one company is testing the label.

[ad_2]