Application of RFID sensor tag in blood quality control management

[ad_1]

The feasibility of using RFID fusion sensing technology for blood management

The general flow of blood management business is: blood donation registration, integrated blood sample testing, blood collection, blood bank, bank management (component processing, etc.), blood out of bank, and hospital for use (or other blood products). In this process, a lot of data is often involved, including the donor’s information, blood type, blood collection time, location, and the person who handles it. A large amount of information has brought certain difficulties to blood management. In addition, blood is a substance that is very easy to deteriorate. If the environmental conditions are not suitable, the quality of blood will be destroyed. Therefore, the quality of blood will be poor during storage and transportation. Real-time monitoring is also critical. RFID and sensor technology are emerging technologies that can solve the above problems and effectively help blood management.

RFID technology can provide each bag of blood with its own unique identity and deposit corresponding information for it. This information is interconnected with the back-end database. Therefore, whether the blood is in the blood collection point, the mobilization point blood bank, or the point of use hospital , Can be monitored by the RFID system in the whole process, and the blood information at each transfer point can be tracked at any time. In the past, the blood bank was time-consuming and laborious, and manual information verification was required before use. After the use of RFID technology, large quantities of data can be collected, transmitted, checked and updated in real time without precise positioning, which speeds up the flow of blood. Library identification also avoids the errors that often occur in manual verification. The non-contact identification feature of RFID can also ensure that the blood can be identified and tested under the condition that it will not be contaminated, reducing the possibility of blood contamination. It is not afraid of dust, stains, low temperature, etc., and can be used in special storage of blood. Maintain normal work under environmental conditions.

Sensing technology is a window for sensing, acquiring and detecting information. It can realize data collection and quantification, processing fusion and transmission applications. Through the real-time monitoring and collection of the blood environment temperature, sealing condition and oscillation degree by the sensor, and the timely processing and response of the sensing information through the system, the deterioration of blood can be effectively avoided and the quality of blood can be guaranteed.

Combining RFID and sensor technology, using RFID sensor tags that can not only improve identification efficiency, realize information tracking, but also monitor the quality of items in real time, can truly realize the intelligent informatization of blood management.

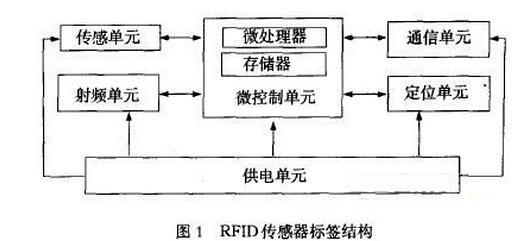

Design of RFID sensor tag

The RFID sensor tag is mainly composed of a micro control unit, a sensing unit, a radio frequency unit, a communication unit, a positioning unit and a power supply unit, as shown in Figure 1.

1 Micro control unit

The micro control unit is composed of an embedded system, including an embedded microprocessor, a memory, an embedded operating system, etc. It also integrates a watchdog, timer/counter, synchronous/asynchronous serial interface, A/D and D/ Various necessary functions and peripheral equipment such as A converter and I/O. The main functions realized by this unit include: responsible for task allocation and scheduling of the entire chip, data integration and transmission, wireless data verification, completion of data analysis, storage and forwarding, intra-area network routing maintenance, and chip power consumption management Wait.

2 Sensing unit

The sensing unit is mainly composed of a sensor and an A/D converter. A sensor is a device or device that can sense a prescribed measurement and convert it into a usable output signal according to a certain rule. Usually the sensor is composed of a sensitive element and a conversion element. The sensitive element collects information that needs to be sensed from the outside and sends it to the conversion element. The latter completes the conversion of the above-mentioned physical quantities into the original electrical signal that can be recognized by the system, and passes through the integration circuit and the amplifier circuit. The shaping process is finally converted into a digital signal by A/D and sent to the micro-control unit for further processing.

Taking into account the requirements for environmental conditions of blood storage and transportation, this sensor unit includes functions for testing multiple physical signals such as temperature, pressure, sensitivity, and oscillation in the monitoring area.

3 RF unit

The radio frequency unit controls the reception and transmission of radio frequency signals, and selects and uses space division multiplexing, time division multiplexing, frequency division multiplexing and code division multiplexing access methods to realize multiple target simultaneous identification and system anti-collision mechanisms.

4 Communication unit

The communication unit is used for data communication, to solve the carrier frequency band selection, data transmission rate, signal modulation, coding method, etc. in wireless communication, and to send and receive data between the chip and the reader through the antenna, with data fusion, request arbitration and routing Select and other functions.

5 Positioning unit

The positioning unit realizes the positioning of the chip’s own position and the positioning of the information transmission position. Based on wireless transmission protocol, such as IEEE802.15.4 standard and ZigBee protocol, etc. The positioning algorithm can be based on ranging (such as signal strength ranging, time difference ranging, etc.) or not based on ranging methods (such as centroid method, DV-Hop algorithm, etc.).

6 Power supply unit

RFID sensor tags are divided into passive, semi-passive and active. Passive tags do not require a built-in battery on the chip. They maintain operation by extracting the radio frequency energy emitted by the reader. Both semi-passive and active tags require internal battery power to maintain normal sensing and radio frequency operation.Considering that the real-time monitoring of blood products in blood management needs to ensure its continuous and normal energy supply, a power supply unit is added, which is designed as a semi-passive or active tag[4].

In this part, by reasonably setting the chip’s receiving, transmitting and standby states, the problems of energy consumption and transmission reliability can be solved, and the service life of the chip can be effectively extended.

Application of RFID sensor tag in blood management

It mainly introduces the three aspects of blood storage management, blood tracking management, and blood quality control management, and points out the effective role of RFID fusion sensor technology in blood management.

1 Blood storage management

(1) Blood storage

The staff put the blood bags on the conveyor belt and pass them in sequence. The bottom of the conveyor belt is equipped with an RFID reader. When the RFID sensor tag attached to the blood bag enters the reading range, the information on the tag is read out. The middleware is filtered and transmitted to the background database. At the same time, the system displays the blood type, type, specification and other information on the screen at the exit of the conveyor belt. The staff will put the blood in the designated storage tray according to the displayed content.

According to the recognized blood type, type, specification, quantity, etc., the back-end system recognizes the cargo space in the blood bank and finds the existing empty cargo space that meets the specifications and quantity. The realization of this step is mainly by pasting an RFID tag on each shelf, and writing the type, type, specification, quantity and other information of the blood it should store through the reader. When there is a blood bag on this shelf When loading, the staff use the handheld reader to write the RFID tag. When the blood bag on the shelf is out of the warehouse or move, the staff uses the handheld reader to clear and write the RFID tag. , And the reader installed on the top of the blood bank will read each shelf label when instructed by the system. If it finds that the shelf has been cleared and meets the storage conditions, it will notify the system, and the system will The specific number is displayed on the screen at the warehouse, telling the staff which types of blood should be placed on which shelves.

After being instructed, the staff will send blood of various specifications to the designated area for refrigerated storage.At the same time, the reader writes the warehousing time, warehousing type, blood sender, blood receiver and other information of each blood bag into the RFID system[5].

(2) Blood out of the bank

The system issues a shipment order and instructs the staff to go to the designated area to take out the specified type, specification and quantity of blood. If the amount of blood taken is small, the staff can use a handheld reader to directly read the blood information; if the amount of blood taken is large, the staff can use a conveyor belt to transport the blood out of the library and read its information. The information read out is transmitted to the system and checked against the back-end database. If it is correct, it is allowed to leave the library. During the outbound process, the RFID system records the outbound time, blood expiration date and other secondary information.

The order of the blood out of the library is determined by the system after reading the information and analyzing it. The blood of the same specification is required to follow the principle of first in, first out to avoid the phenomenon of overstocking and blood expiration and waste. The blood in the blood bank marked as “pending test” is prohibited from leaving the bank to ensure the quality of the blood out of the bank.

2 Blood tracking management

The blood tracking management adopts a cluster-based hierarchical structure. Each cluster head is a distributed information processing center, which is used to collect the data of each cluster member and complete the processing and fusion of the data. Then the data is transmitted to the upper cluster head, and then passed in turn. Finally, all the data is filtered and processed. After integration, it is transmitted to the highest-level cluster head, and the reverse process is the information query process. The data is unfolded layer by layer and tracked in an orderly manner. Here, the cluster head at the highest level is equivalent to the blood information center of the whole country, and the cluster head at the next high level is equivalent to the blood information center of each province, autonomous region, and municipality directly under the Central Government. This layered structure disperses information, avoids centralized storage, solves the problem of excessive information, and improves the security of the system. Information exchange and transmission are carried out directly between the child layer and the parent layer, which facilitates query and tracking. The structure is shown in Figure 2.

The process of depositing blood information is as follows: First, store the RFID identification code of each bag of blood and its corresponding information in the database of the primary blood station, then fuse the information of the primary blood station, and combine the identification code with the effective IP of the primary blood station The address is stored in the local municipal blood information center database, and then the information of the municipal blood information center is merged, and the identification code and the effective IP address of the municipal blood information center are stored in the local provincial blood information center database. Finally Then integrate the information of the provincial blood information center, and save the identification code and the effective IP address of the provincial blood information center into the national blood information center database (if necessary, you can also reconnect the identification code to the national blood information center The effective IP address is stored in the global blood information center database for global blood information interconnection)[6-7].

The blood information tracking process is as follows: According to the RFID identification code, first search for the province information of the bag of blood in the database of the National Blood Information Center, and enter the provincial blood information center database according to the found IP address to search for the bag of blood. City information, according to the found IP address, enter the city-level blood information center database to find the blood station to which the bag of blood belongs, and according to the found IP address, enter the blood station database, and according to the information, you can know the current status of the bag of blood Whether the status is saved in the library, used in the warehouse, or has been deteriorated and discarded, if it has been used, you can further find all the user’s information.

3 Blood quality control management

Blood is very sensitive to temperature changes. If the ambient temperature is not suitable, the substances in the blood will be destroyed, which will affect the quality and shelf life of the blood. In the process of storage, transfer and transportation, the blood should avoid violent shaking. In addition, the blood packaging should be sealed. If bacterial contamination is caused by punctures or other factors, the blood will be discarded.

The RFID sensor tag attached to the blood bag will monitor the environment around the blood bag in real time, measure the surrounding temperature, pressure, sensitivity, vibration and other physical signals at regular intervals, and record the measurement data in the tag chip . The system will set a standard range inside the tag. Once the current measured data is lower than the lower limit of the range or higher than the upper limit of the range, the tag will actively transmit a radio frequency signal to activate the alarm device to remind the staff.

If the blood bag is in the storage state of the blood bank to alarm, then according to the received radio frequency signal, the current position of the alarm blood bag (bank area, shelf, RFID identification code, etc.) will be displayed on the alarm display screen, so that the staff can find out and Handling; if the blood bag is in transit to alarm, the alarm device can be installed on the transport storage to alert the staff with whining or flashing light. When the staff finds out, they use the handheld reader to receive the radio frequency signal and find the alarm according to the identification code. Blood bag.

Once the blood is suspected to be deteriorated or contaminated, the staff will use the reader to set the label to the “pending inspection” status, and it is not allowed to leave the warehouse. It is not allowed to be used at the point of use. After the test is confirmed to be unusable , High-pressure disinfection and incineration will be carried out. At this time, the staff will write the scrap information and the reason for the scrap to the system with the RFID identification code of the bag of blood, so as to prepare for the follow-up blood tracking.

For the returned blood, in addition to manual further testing of the blood quality, the data record of the RFID sensor tag can also be used to find out the problematic links in the whole process of the blood from the blood collection to the blood supply to the blood withdrawal, and find out who should be responsible Analyze the reasons and avoid the occurrence of similar situations next time.

Blood is not only the source of life, but also a channel for the spread of many diseases. Common diseases spread through blood transfusion or blood products include: hepatitis B, hepatitis C, AIDS, syphilis, malaria, sepsis, etc. Most of them are difficult to cure. In order to avoid disease transmission or medical accidents caused by irregular blood collection, chaotic management of bagged blood, or improper blood transfusion, it is imperative to strengthen blood management and ensure the safety of blood use. At present, the combined application of RFID and sensor technology is not very extensive, but it has shown broad application prospects. This article proposes an RFID sensor tag designed by combining these two technologies, and analyzes the advantages and feasibility of applying it to blood management.

Blood management is a work that does not allow errors. The application of RFID sensor tags not only makes the entire supply chain management visible, transparent, and free from pollution, but also enables real-time monitoring and interconnected tracking of information and quality, which truly saves blood Management informatization and medical management informatization work have been extended to the end, and have been implemented in practice, enabling the realization of fully individualized humanistic care.

[ad_2]