Renwei Electronic Mining Vehicle Weighing System

[ad_1]

1. System significance

1) The entry and exit of material transportation vehicles requires procedures such as parking, registration, and weighing. The operator manually enters the data into the computer, which is not only time-consuming, but also has a large error rate. The use of an automatic vehicle weighing system can improve work efficiency and reduce errors Rate.

2) Automatic management is fully realized, human intervention in measurement is avoided, human error can be effectively eliminated, and the accuracy of original data collection can be guaranteed.

3) It solves the phenomenon of man-made cheating such as car cloning and repeated weighing, reduces economic losses, plugs the gap for enterprises, and saves a lot of money.

4) Prevent over-balance blockage, greatly reducing the labor intensity of the staff.

2. System architecture and program description

The mining vehicle weighing system is designed and developed by Shanghai Renwei Electronic Technology Co., Ltd. according to the characteristics of existing vehicle weighing, to make up for the lack of manual weighing, and achieve the purpose of automatic identification and automatic weighing. The system integrates radio frequency technology identification, remote centralized video monitoring, key links of vehicle panoramic and close-range image capture, and intelligent weighing room control equipment management as an integrated vehicle intelligent weighing management system. It is suitable for enterprises and institutions (such as steel mills, mines, grain depots, etc.) that frequently enter and exit large quantities of raw materials and products.

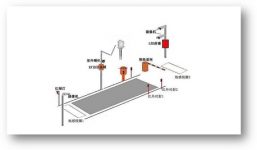

System network architecture

2.1 Program description

The authorized dual-frequency electronic tag is placed on the windshield of the car. When the vehicle passes through the 125K induction coil in front of the barrier, an induction signal is generated to wake up the dual-frequency electronic tag on the vehicle, and the remote reader reads the vehicle Electronic label information, upload the label information to the host database, and call out the vehicle information at the same time. The infrared beam detects whether the vehicle is directly above the weighbridge, if the vehicle is standing, the vehicle is weighed on the scale, the display screen displays the weighed weight information, and the vehicle image information is captured at the same time. After the weighing is completed, the vehicle is weighed down, and after passing the induction coil embedded behind the exit barrier, the exit barrier is released by lifting the rod. After the vehicle is released, the exit barrier will be closed and the entrance barrier will be lifted, allowing the next vehicle to enter. In the application of the system, the electronic tag is generally installed on the inner side of the front windshield of the transportation vehicle. In order to better handle the related services carried by the information of the carried materials, the system generally requires tags to have a larger data capacity. At the same time, to prevent internal fraud, once information is written into the tag, it is required that the internal information of the tag cannot be illegally tampered with. On the other hand, in order to prevent the vehicle from over-licensing, the label can be installed with anti-disassembly: once the installation is completed, after it is disassembled without legal authorization, the system will alarm, and the label must be reset and used again after tampering.

Three, case introduction

Intelligent vehicle identification and weighing project of a cargo yard in Harbin

[ad_2]