RFID automatic identification system for weighing vehicles has been successfully applied

[ad_1]

Recently, the radio frequency identification technology (RFID) weighing vehicle management system has been successfully applied to weighing vehicles, which solves the problems of vehicle mixing and low work efficiency faced by the fuel transportation vehicles of the Xiahuayuan Power Plant of Datang International Power Group in the weighing management link. . With the successful application of this system in Datang International Power Group, other local power plants will subsequently adopt this system. At present, Zhangjiakou Shalingzi Power Plant has begun to use this system. In the near future, this system will be popularized in power production enterprises.

Zhangjiakou Xiahuayuan Power Plant is an electric power production enterprise under Datang International Power Group. It has a current generating capacity of 400,000 kilowatts. In order to achieve sustainable development, Xiahuayuan Power Plant plans to expand the sixth phase of the project. The engineering design is two 600,000 kilowatt air-cooled units. Domestic coal-fired units. It currently consumes 5,000 tons of coal per day and is one of the important power generation companies in the Beijing-Tianjin-Tangshan region of Datang International.

The weighing vehicle management system is implemented in the Xiahuayuan Power Plant. According to Xie Huayuan, the head of the fuel department of Xiahuayuan Power Plant, the fuel department, as the raw material supply department of the power plant, occupies a very important position in the entire work process. The quality of its coal and the amount of coal The calculation directly affects the economic benefits of the power plant. Therefore, the management of the fuel department of the power plant is obviously important. The important point in the management is to avoid human operation errors or fraudulent behaviors. It is the solution to the two behaviors of fraud operations. We believe that software processes can be used to replace manual processes, and RFID technology can be used to solve human operations and human fraud.

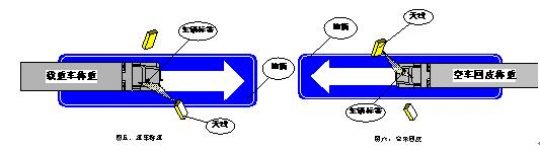

In the design of the management plan for the weighing vehicle of Weishen Technology Company, the electronic tag reader is used to write the vehicle information into the corresponding electronic tag and associate it with the coal supply unit in the background database, and the electronic tag of the vehicle is glued to the front gear of the vehicle On the windshield, UHF readers are used to remotely identify vehicles. The driver can complete the weighing process without getting off the car and swiping his card, which greatly improves efficiency. At the same time, the UHF vehicle electronic tag is used to give each car a unique electronic tag identification that is difficult to forge, which solves the problem of other vehicles replacing this car into the factory.

The weighing vehicle drives onto the weighing platform, and the antenna starts to scan the tags on the vehicle. After the vehicle is stopped, the system automatically associates the tag information with the weight of the coal contained in the vehicle. The operation is similar to that of weighing when the vehicle is recovered. When the vehicle tag is recognized in the system, it will be automatically associated with the relevant information of the vehicle, so that the status of the coal contained in the vehicle can be obtained. In the software, it is distinguished whether the vehicle is to be weighed or recovered.

Software platform required by the system:

Truck scale sampling management system

Truck scale sample management system

Truck scale weighing management system

Truck Scale Test Management System

Manager application software system

In terms of fuel sampling and laboratory management, we use an electronic label (which can be recycled for a long time) for each coal sample and package it in a coal bag on-site. Information, only the manager knows the fuel company to which the code corresponds, thus preventing human cheating.

A spokesperson for the Xiahuayuan Power Plant said: In the past work of the power plant fuel sampling, sample preparation, and laboratory testing, due to excessive human factors, shoddy vehicles and mixed vehicles often occurred, which caused a lot of economic losses to the power plant. In addition, in the previous vehicle weighing process, manual input of vehicle information or high-frequency read-write equipment or magnetic card equipment was required. This required the driver to get out of the car to swipe the card every time, which resulted in low work efficiency and frequent errors due to human negligence. Therefore, using new RFID technology and high-tech means to make fuel management more confidential and vehicle management more intelligent and automated is an important way to improve management efficiency.

The successful implementation of a series of weighing vehicle management projects in the steel industry shows that automatic identification technology has a wide range of application prospects in the field of weighing vehicle intelligent identification. Weishen Technology has successfully applied advanced automatic identification technology in production, manufacturing, telecommunications, power, finance, government, transportation, medical and health and other industries. It has a wide range and stability represented by China Post and China Mobile. The enterprise user group has formed a distribution agency network and a service support system covering the whole country with a marketing network in North China, Northeast China, East China, South China, Central China, and West China. In the domestic UHF-RFID industry application field, Weishen Technology has always been a leader in the market, actively innovating, and able to promptly propose solutions and technical services at critical moments. The implementation of the weighing vehicle management plan for Xiahuayuan Power Plant has provided valuable experience in the application of RFID radio frequency identification technology in other power companies, and it has a huge promotion effect in the national power industry.

[ad_2]