St. Luke’s Hospital in Kansas City uses RFID to manage medical equipment

[ad_1]

The Cardiovascular (CV) laboratory in Kansas City uses passive EPC RFID tags and readers to enable the hospital to better manage its inventory of pacemakers, coronary stents and defibrillators. By improving the tracking and control of these devices, the coronary artery equipment alone has reduced the cost of 500,000 US dollars, and more accurately reduced the medical expenses of such patients. The RFID system also helps St. Luke save hundreds of thousands of dollars each year, and use the saved costs to buy more medical devices, thereby earning more income.

Before installing this system, the laboratory’s equipment was coordinated and managed by nurses, doctors, and other medical personnel. It was necessary to manually scan the barcode on the equipment package, and then check it with the barcode scanned information on the patient’s wristband. Now, on the basis of the original barcode label, an ultra-high frequency Gen2 tag is embedded, and the movement information of the instrument from the inventory to the operating room can be read using an RFID reader. David Strelow, Director of Cardiovascular Laboratory, said: Thanks to the invention of the new label, St. Luke’s Hospital has adopted a product tracking system that is different from the one deployed by Wal-Mart.

Cenbion Medical is a laboratory that develops inventory management software. It used barcode technology to manage inventory and developed a set of solutions based on EPC Gen 2 RFID (Squiggle inlay produced by Alien, with 3 chips embedded in the tag). The solution also includes FX7400 reader and AN480 antenna manufactured by Motorola.

The laboratory adopted Cenbion’s plan at the end of 2006 and proposed to start pilot projects in early 2007. Cenbion has spent several years seeking RFID hardware partners to help it design a reader and antenna architecture that can provide reliable performance. The company finally reached a partnership with Motorola. The two companies will jointly provide St. Luke with an excellent system solution. The hospital decided to deploy the current solution in early 2011.

When the high-value equipment ordered by St. Luke’s Hospital arrives, laboratory employees use a barcode scanner to collect the International Commodity Barcode (EAN) printed on the packaging. Then, the software developed by Centbion will automatically instruct the Zebra R110Xi RFID printer to print the Alien label. Randal York, president of Cenbion, said: The software generates a unique identification number, which can be used as a barcode printed on the label or encoded into the label to cover the label number at the factory. This unique code contains the batch and expiration data of the equipment, and has a lot to do with the complete EAN printed on the package.

RFID reader antennas are installed at the entrance of the hospital’s warehouse and operating room. When the device moves through these antennas, the RFID reader placed at the door collects the tag data and transmits it to Microsoft’s BizTalk software. BizTalk management software is responsible for preliminary processing and analysis of data, such as filtering out duplicate data. BizTalk is responsible for forwarding the data to the Centbion software, which eventually puts the data into a unified database. The data involved in this process includes the tag number, the time when the data was read, and the location of the reader. When the equipment is in use, the hospital staff should scan the barcode label on the equipment package and the barcode on the patient’s wristband at the same time to ensure the accuracy of billing. But sometimes, this step is easy to miss.

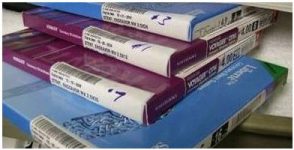

RFID tags for devices such as coronary stents

“The solution involves about 20 different medical devices,” Strelow said. “The nurse is very busy during the operation. It is understandable to forget to scan one or two.” Before the deployment of the RFID system, if this happens, the equipment will eventually disappear from the inventory and will never appear on the patient’s bill. It is difficult to tell the reason for the loss of this asset. Since the use of RFID tags, the use of hospital equipment is clear at a glance. Information such as whether the device is in use, when it was used, and where it is located can all be queried.

More importantly, Strelow said, being able to calculate patient bills more accurately will have a greater economic impact on the hospital. Increasing the expense record by 0.1% per year means that St. Luke has saved $54,000 in unnecessary losses.

Based on the above advantages, the Cardiovascular Department has plans to use RFID tags for inventory inventory instead of using bar code scanners for inventory inventory each year. However, the hospital is very cautious about this. Before Strelow can prove that the RFID tag can achieve a reading accuracy of 99.5%, he intends to continue the manual interrogation with the barcode scanner.

[ad_2]