The management status and information management of high-value medical consumables

[ad_1]

The current situation of medical high-value consumables management and information management? The form of hospitals in my country was first seen in the “Hanshu”, and its main purpose is to save the dead, heal the wounded, and save people. However, there are various problems in the management of high-value consumables in hospitals, caused by various management loopholes and dead ends. The falsely high operating cost of high-value consumables has severely restricted the reduction of the cost of high-value consumables and the improvement of quality in hospitals. Let’s take a look at the current status of medical high-value consumables management and information management?

The current weak link in the management of high-value consumables. Generally manifested as the following problems:

1.1 Incomplete registration of basic data

The first manifestation is that the basic database material names are not standardized, the specifications are not complete, the price of consumables is not adjusted in time, and the price comparison information for different suppliers of similar consumables is incomplete and lagging. The result is that the accounting department cannot accurately book accounts according to the name and price of the standardized high-value consumables, which is not conducive to the management of the department’s ledger, it is impossible to confirm the accurate cost, and it will also cause the purchase price of high-value consumables to be unreasonable; secondly, performance There is a lack of real-time management for the “three certificates” (including product registration certificates, production licenses or operating licenses, and sanitation licenses). Sometimes the validity period of the three certificates has expired, and consumables managers cannot be timely due to lack of effective information support. Discovery; In addition, it is not clear which supplier the high-value consumables are, when, which ward supplies the goods, which patient, when they are used, when the property will make a payment plan for the high value, and when it will be paid; Finally, the contract registration of high-value consumables is not complete. At present, the contract review of high-value consumables in hospitals is not strict from use to payment.

1.2 Irregular use

The manifestation of irregular receipts is that some departments are not fixed, the number of receipts is unfounded, and the statistics platform used by the departments of receipts is lacking, which ultimately leads to the waste of the required materials.

1.3 The “zero inventory” material management process is cumbersome

Zero inventory management is a production management model for enterprises to pursue the maximum benefit of capital use. This model can also be used in hospitals to achieve the effect of reducing the occupation of hospital funds, preventing losses due to improper storage, and reducing storage risks and costs. The definition of high-value consumables control system is that all materials that need to be “zero inventory”, such as high value, high storage conditions or not entering the warehouse (such as: dental porcelain, is directly supplied to the clinic) and other categories Materials can be used as the management category of high-value consumables. The “zero inventory” process is adapted to clinical needs and is commonly used in various hospitals. The manifestation of “zero inventory” management irregularity is that the circulation of materials in the hospital is based on manual work, which can easily lead to errors, omissions, and double accounting.

1.4 Non-standard management of embedded barcodes

Some embedded barcodes have irregularities, such as replacing barcodes with certificates, barcode information is incomplete, barcodes cannot be recognized, and individual products even have no barcodes. The regulations that embedded barcodes must retain barcode data in case data cannot be effectively implemented.

1.5 Many management process loopholes

At present, in order to enter the hospital market, high-value consumables suppliers will operate from equipment, finance and clinical aspects.Most domestic hospitals have more or less management loopholes. The quality of high-value consumables cannot be guaranteed, and financial supervision is strong. Weaker. For example, dental porcelain is generally supplied directly to the clinic by the supplier, and has not been reviewed by relevant departments such as the equipment department. Finance can only passively accept payment, and the supervisory function is lacking.

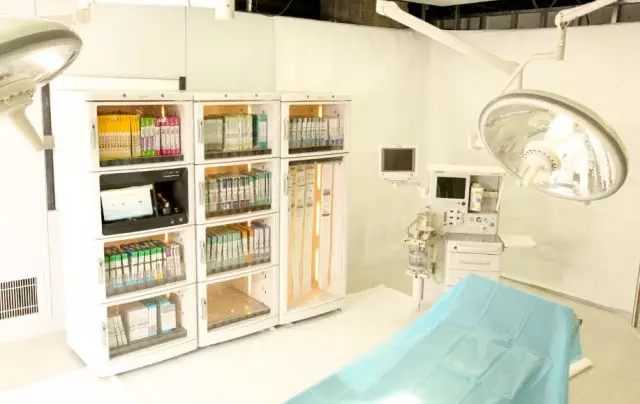

RFID smart consumable cabinet

The RFID smart consumables cabinet is based on the above-mentioned problems and developed a high-efficiency smart cabinet system, which is specially developed to solve the current irregular management of consumables in the medical industry. The smart cabinet operates RFID radio frequency technology, numbers each category or even each consumable, automatically scans and recognizes consumable information, tracks the use process of consumables, and monitors the process from application, purchase, acceptance, receipt, use, and scrap. Covers the life cycle of consumables, and provides accurate data support for the hospital to effectively plan statistics and replenish.

RFID smart consumable cabinet product features:

1. Fast scanning, RFID scanner can quickly scan RFID tags and automatically access relevant data.

2. RFID technology is not limited by product size and appearance in reading, and can be applied to different products and consumables.

3. High accuracy, each consumable is pasted with a unique RFID identification code, and there will be no operator errors.

4. The RFID is equipped with a high-definition touch screen, which is easy to operate.

5. It has the function of opening all doors with one key in the background, which is convenient for the administrator to use in emergency situations.

6. Real-time monitoring of the use of the smart cabinet, feedback and query of the switch status of the cabinet door.

7. Support various door opening methods, such as: WeChat scan code, fingerprint, face, IC card, finger vein, etc.

8. The process of application, purchase, acceptance, receipt, use, and scrapping of each consumable can be recorded and inquired in the background.

9. The RFID smart consumables cabinet can be set up with sub-level administrators, each type of management authority is different, the general management can add and delete a management.

[ad_2]