Zimmer Ohio uses RFID to manage medical orthopedic equipment to speed up order and inventory management

[ad_1]

Zimmer Ohio is the sole agent and sales of orthopedic products and equipment produced by Zimmer Inc. The company is now installing an RFID system to help inventory workers reduce hours of work a day, while improving the visibility of high-value items shipped to the hospital or returning to the warehouse. .

Zimmer Ohio supplies Zimmer orthopedic implant equipment and surgical instrument product lines to hospitals in the Ohio area. Usually, when a surgeon plans an operation, such as a hip replacement, the hospital will place an order from Zimmer Ohio for a variety of implantable devices that may be used during the operation, and trays containing surgical instruments. Zimmer Ohio usually sends hundreds of items during an operation, but only some of the equipment is actually used in the operation, and the rest are returned to one of Zimmer Ohio’s two warehouses in Columbus and Hudson.

Zimmer must try to avoid errors in the delivery of surgical instruments, said John Reese, operations manager at the Zimmer Ohio Columbus warehouse. For this reason, the company specially hires inventory experts to check each order for several hours a day to ensure the correctness of each shipment. The equipment must undergo four inspections before being shipped to the hospital.

Aluminum surgical tool trays (dimensions 22 inches * 10 inches, heights ranging from 1 inch to 8 inches) are the most time-consuming inspections because they usually contain hundreds of small items-for example, piles of 0.09 Inch drill bit, and everything must be counted one by one. The price of a single pallet and its contents ranges from US$1,000 to US$20,000, Reese said, so the company must ensure that the pallet is not lost. After the operation, the hospital sterilized the entire tray and its contents, then wrapped the tray with plastic film and placed it on a shelf corresponding to its supplier, such as Zimmer Ohio, waiting for the driver to transport it out. In order to confirm the identity of the pallet, Zimmer Ohio or the hospital may need to inspect the contents of the pallet, after which it must be re-sterilized and repackaged.

For several years, Zimmer Ohio has been looking for an automated solution to reduce order confirmation time. However, when the company began researching RFID technology a few years ago, Reese said that the cost of the tag at that time made the investment in the implementation of the entire application too expensive. It wasn’t until the fall of 2009 that the company formally started cooperation with RFID Enabled Solutions (RES).

Zimmer and RES believe that the commonly used channel readers-which require labeled items to be placed on a conveyor belt one at a time, and then pass through the reading area of the RFID reader-require changes to the existing packaging process and are not flexible enough. When picking up the order, employees collect the items according to a pick-up list and place them on a metal cart. RES then developed an RFID channel that can accommodate an entire metal cart, which can read every tag in the cart at the same time, says RES creator Neco Can.

The channel contains an UHF EPC Gen 2 RFID reader and antenna. Zimmer conducted a series of tests on the channel, and Reese said that the tags of the implantable device and the tray achieved 100% accuracy. It is theoretically feasible to label each item in the pallet. However, because many items are too small in size, they cannot be labeled normally, or they cannot work normally after being labeled. Therefore, Zimmer and RES came up with a solution: the company installed a scale with an embedded RFID reader next to the channel reader. Before the company sent the surgical tray to the hospital for the first time, Zimmer inspected each item in the tray, recorded and photographed each item, and weighed it. The scale is very sensitive. When the pallet returns from the hospital, the company weighs the pallet to determine if any tools are missing or contain wrong tools.

The cart loaded with pallets and implantable devices is pushed into a special RFID channel reader

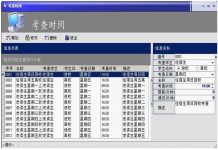

When the system is officially launched, it is expected that in July 2010-all single implantable items and trays filled with surgical tools will be labeled with UHF EPC Gen 2 tags. The passive RFID inlay of each label will be encoded with a unique ID code, which is also printed on the front of the label in the form of a barcode. When each new item is labeled, workers only need to use a bar code reader to register the asset into the AIMS RFID inventory and order management software system running on the Zimmer Ohio server RES, which receives and compiles the surgical pallet scale and reader And then forward the information to the company’s existing inventory system.

Trays loaded with appliances, identified by passive UHF tags

When the hospital places an order, the Zimmer staff enters the AIMS software to receive the order information and print a list of all the items to be packed and pallets. Workers remove implantable items and pallets from warehouse shelves and place them in metal trailers. After the order is picked up, the worker pushes the cart onto a scale with a touch screen to weigh each pallet. An RFID reader under the scale reads the ID code of the pallet label, and the AIMS software then displays a list indicating the description and pictures of each item that must be placed on the pallet, and the weight of the pallet.

At the same time, the pallet weight data together with the ID code of the pallet RFID tag will be sent to the computer software via a cable connection, which is compared with the information about the pallet that the software has stored. If the pallet weight does not meet expectations, the system will display an alert on the screen. If the weights are the same, the system confirms the correctness of the pallet, and the screen displays the word “Passed”. A screen shot of the tray content will be used as the basis for confirmation.

The staff put the cart loaded with pallets and implantable devices into the RFID channel, a 7-foot-tall box, and then closed the door to reduce the chance of reading labeled items outside the channel. When the reader reads the ID codes of all items, the AIMS software compares the actual quantity with the pick-up list. If there is an error in the order, the system displays an alert. Otherwise, AIMS approves the order and informs Zimmer warehouse software that the order is ready for shipment.

When the pallets and unused orthopedic equipment are returned from the hospital to the warehouse, they are placed in the RFID channel again, and the AIMS software will upgrade the Zimmer software to indicate which items are returned. Items not returned will be invoiced. The pallet is weighed again and compared with the set weight of the pallet to confirm.

RES encountered several challenges when developing this system. The company’s design of channel readers must be suitable for metal trays, and the labels used must also be able to withstand the strict disinfection of the hospital (for example, placed in an environment with a temperature of 375 degrees Celsius for 3 hours).

RES also provided the company with two hand-held RFID readers for inventory counting of implantable devices and tool trays. Currently, a comprehensive inventory count requires 40 man-hours to complete. With the new RFID system, inventory counting takes only 20 minutes, and employees do not need to check the order items four times before sending.

Zimmer expects a return on investment within one year of system operation.

[ad_2]