U.S. Army Training Center uses RFID technology to manage uniforms

[ad_1]

Fort Leonard Wood Recruit Training Center (RTC) is the first 3 adoptions in the United StatesRFIDOne of the U.S. Army recruit training centers that systematically manages uniforms received from the Atlanta warehouse. The warehouse is operated by Lion-Vallen (LVI). This UHF RFID system is provided by Advantech, which allows RTC and DLA (National Defense Logistics Agency) to automate clothing reception and distribution management.

DLA has used uniform tracking RFID systems in several other boot camps, and San Antonio Lackland Air Force Base was the first to adopt it. Fort Leonard Wood’s RFID system was installed in October 2014, and then two other training centers were introduced. In the future, DLA plans to deploy this system at the Fort Sill Army Training Center.

Fort Leonard Wood receives 20,000 recruits each year, and they receive uniforms at the uniform distribution point (CIIP) in the center of the training camp.

The supplier of DLA is responsible for delivering the marked uniforms to the warehouses operated by LVI or other third-party inventory management companies of DLA, and then these uniforms will eventually be delivered to the training camp. DLA uniform manager Monique Williams said that initially, the current RFID deployment is in Phase 1. Suppliers will attach RFID tags to uniforms such as shoes, pants, and T-shirts worn by soldiers for daily training. Smaller, cheaper items like belts, badges and socks are not marked. Advantech project manager Doug DeLoach said that in fact, some socks made of metal fiber are very difficult to read. In the next stage, formal event dress uniforms will be added to the mark list.

DeLoach explained that when receiving an order from DLA, the uniform provider will use the virtual item management-ARN supply chain automated processing (VIM-ASAP) software provided by the agency to see which items need to be shipped. Then, the supplier will enter the items to be delivered into the VIM-ASAP system, and DLA employees can view it. He said that before the RFID system was used, the system had been in use for 10 years. Now, the supplier will also enter the ID number of the tag attached to the item and the ID number of the RFID tag on the outer packaging box.

Angela Richwine, DLA’s apparel supply chain business process analyst, said that more than a year ago, DLA began to require suppliers to mark items and their boxes. Richwine also said that 99% of Phase 1 items will be sent to the LVI warehouse and marked by the warehouse staff.

When the goods are delivered to the recruit training center, the VIM-ASAP software creates a list. When the items are delivered to RTC according to the order, the LVI staff will mark the unclosed boxes in the warehouse.

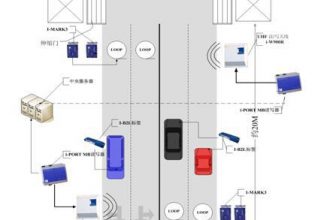

These boxes will be transported to the CIIP in the training center. At Fort Wood, employees drive trucks to deliver these items to CIIP’s storage area. The driver needs to drive the truck loaded with cargo through the entrance where the Impinj xPortal reader is installed. After the reader reads the tag ID number, it will transmit the data to the ARN Integrated Retail Module (IRM)/RFID software provided by Advantech. At the same time, the ARN RFID/IRM software will compare the differences between the read items and the list. When the truck is unloading, the warehouse clerk needs to stare at the computer screen to ensure that the order of receipt is correct, and that no items are missing or there are no items outside the list. Fort Leonard Wood uses IRM to check on-site items and which items need to be distributed. This data can also be shared with the DLA, which provides a visualization of the inventory.

Uniform distribution is the second use scenario of RFID. The recruits come to RTC to receive a list of items to be picked up. This list will indicate the items to be picked up and attach an application number with a QR code. The staff at Fort Leonard Wood RTC will distribute items based on this list. Then, the staff walked to the RFID counter (built-in RFID reader and antenna), and placed the distributed items on the counter.

Then, RTC employees need to scan the QR code on the item list and open the IRM RFID application, which will display the demand list and activate the reader. Then, the reader will read the item tag ID number, and the IRM RFID software will compare the read ID number with the demand list to ensure that the uniforms distributed are completely correct. If the system shows no abnormalities, the recruits can pick up these items. Then, the IRM software transmits the data to the VIM-ASAP system.

Williams said Fort Leonard Wood is still evaluating the benefits of the technology. He said: “There is a learning curve here.” For example, in order to increase the reading rate of the reader, the RFID team adjusted the power of the reader and placed a shielding fabric around it. Richwine explained that in the past few months, the training center has been working hard to ensure the normal operation of the system.

This summer, Fort Sill will also deploy a similar RFID solution, which only involves training uniforms.

[ad_2]