U.S. Navy uses RFID technology to track supplies on Oahu, Hawaii

[ad_1]

The Navy’s Automatic Identification Project (AIT) implemented by the U.S. Navy uses an RFID system to track the transit of materials and equipment at the Pearl Harbor Naval Base warehouse and the Marine Corps Kaneo West Base warehouse (both warehouses are located on Oahu, Hawaii) . The system was launched in June of this year and is expected to improve the visibility of supplies to and from Oahu by the Navy and Marine Corps.

GlobeRanger provides software, middleware and system integration for this system. XIO Strategies, a Washington-based supply chain management consulting company, provided project management, and Alien Technology and Psion Teklogix provided hardware.

The two Oahu bases receive and send materials sent to the military or other bases, or damaged equipment that needs to be sent to the United States for repairs. In another application case, the US Defense Logistics Agency (DLA) attached Alien EPC Gen 2 passive UHF RFID tags to materials at the Pearl Harbor base. By scanning the label, the tag ID code corresponds to the product code of the labeled item, and the product code corresponds to the item data in the Navy’s multiple legacy systems.

U.S. Navy uses RFID technology to track supplies on Oahu, Hawaii

Prior to adopting the RFID tracking system, GlobeRanger senior sales director Michael Bigbee stated that the Navy could not gain visibility into the flow of materials between warehouses in different bases or the materials stored in warehouses. Although active RFID tags are often used in containers shipped overseas, and the tags are scanned at the port, the Navy cannot track the supplies at other points in the supply chain. Without real-time data on asset locations, Oahu military personnel sometimes order surplus and unnecessary supplies. The Navy also has no way of knowing when the items were delivered, when they arrived at the next location, or where they were when they were delayed.

In 2008, the Navy worked with GlobeRanger to solve this problem. The biggest challenge GlobeRanger encountered was the problem of data management. The various legacy systems used by different bases and departments of the Navy manage data. The Navy is now converting to adopt a set of SAP ERP system (system conversion is expected to be completed in 2015-2017). The Defense Logistics Agency requires that the RFID solution used can not only work with a variety of existing legacy systems, but also can be easily converted to SAP ERP software. At Marine Corps, the system will be converted to Oracle ERP software.

The system designed by GlobeRanger can work with the existing legacy management system, and it can also be easily converted to SAP. XIO Strategies provides project management to coordinate data transfer between multiple systems. GlobeRanger’s iMotion edgeware manages the reader, and GlobeRanger middleware compiles and transmits the read data to the military legacy back-end system. “This is the biggest challenge for this application,” Bigbee said.

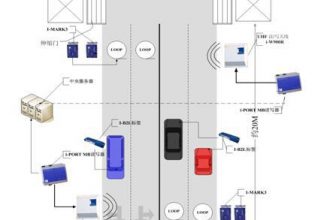

When an item arrives at the DLA warehouse in Pearl Harbor (regardless of whether it is sent to Marine Corps or the Navy), military personnel attach an Alien RFID tag to it, then scan it to match it with the item information. Alien RFID portal readers read tags when items move into or leave the DLA warehouse, the Navy at Pearl Harbor, or the Marine Corps warehouse at Kaneo West. Readers have been installed in the DLA warehouse, and GlobeRanger has installed an RFID reader for each of the Marine Corps warehouse and the three naval warehouses at Pearl Harbor.

The fixed reader obtains the data read each time and sends it to the back-end systems of the Navy and Marine Corps through a cable connection. When the driver took away a labeled item, he used the Psion Teklogix fixed handset with an embedded RFID reader to scan again, indicating that the item was taken away by the driver. When the goods are delivered to another base, the driver scans the RFID tag again.

The military can not only use RFID reading data to locate items, but also perform business analysis, such as tracking transportation time, or receiving or sending shipping notifications.

[ad_2]