10 factors restrict the scale application of RFID series in the packaging field

[ad_1]

RFID, radio frequency identification technology, has been enriched and improved with the advancement of science and technology since its theoretical foundation was laid in the middle of the 20th century. Since the beginning of this century, RFID products, such as single-chip electronic tags, multi-function electronic tag reading, wireless readable and writable, long-distance identification of passive electronic tags, and RF1D adapted to high-speed moving objects, are becoming a reality and are developed abroad. It has gradually been widely used in the country. Moreover, the advantages of multifunctional electronic tags based on RFID technology in the packaging field are obvious. RFID can obtain information about products, locations, times, and transactions in an automatic way quickly, easily and accurately. No need to touch, see the target, even if the item is firmly packed or the environment is not suitable, it will not affect its identification function, which is a major feature of RFID which is different from bar code. In addition, RFID is not just a code. It can read and write data, store data in the processing system, and connect it to a PC or PLC network. RFID can improve data quality, cargo management, and data persistence. The application of RFID in the supply chain can improve management and strengthen the terminal-to-terminal connection. The operation of RFID does not require human intervention. It operates wirelessly and has read-write functions. It will also be a revolution in logistics management.

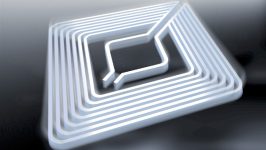

RFID is a non-contact automatic identification technology. The simplest RFID system consists of three main parts: tags, readers, antennas, and data management systems. The electronic tag is composed of an antenna and an RFID chip, and each chip contains a unique identification code to indicate the object attached to the electronic tag. The reader is used to read and write the information in the electronic tag. The reader communicates with other computers or systems through the network to complete the information acquisition, interpretation and data management of the electronic tag. The data management system mainly completes the storage and management of data information. It can be a simple small database or a large ERP database management software integrated with an RFID management module.

The working principle of RFID is not complicated: After the tag enters the magnetic field, it receives the radio frequency signal from the reader, and uses the energy obtained by the induced current to send out the product information stored in the chip, or actively send a signal of a certain frequency, the reader After the information is read and decoded, it is sent to the central information system for relevant data processing.

The standard structure of the RFID label should be three layers, the pressure-sensitive face paper and the electronic label module are compounded together, and then a peeling layer is added. Among them, the electronic tag module contains an antenna and a chip, which is the core part of the RFID tag. RFID tags can be roughly divided into several categories: according to different radio frequency cards, they can be divided into read-write cards, write-once read-write cards and read-only cards. As the name suggests, the first two types of cards can read the information with the reader, and can also rewrite the information. The read-only card can only be read during the entire circulation process, and the information on the card cannot be rewritten.

Electronic tags can also be divided into three types: active, semi-active and passive. The active and semi-active tags have radio frequency energy that has a larger recognition range and can record information sent by certain types of sensors. Passive tags obtain energy from the radio frequency field of the reader and do not need integrated energy.

At present, electronic tags are mainly used in the field of containers or large-package products or products with high single product value. Electronic tags can combine all links of the supply chain into an organic whole, improving logistics efficiency, reducing logistics costs, and products in progress. It has significant advantages in quality traceability and product information loading, and has shown a strong momentum of development. However, RFID technology is still not fully mature, and there are still many factors restricting its large-scale application in the packaging field. With the speed of the development of computer technology, the following factors can be improved due to the advancement of science and technology. This is what this article will focus on.

1 RFID system cost

The cost of RFID system has always been a key factor restricting its wide application. The cost of RFID tags and components varies according to the technology used. For example: Compared with the writable type, the read-only type is relatively cheap; the passive type is relatively better than the active type. In addition, profit margins, label structure, and order size all affect label costs. At present, although the cost of the RFID system has dropped a lot, in the past 10 years, the average selling price of an RFID tag has dropped from US$100 to US$1. Many RFID tag experts predict that the cost of RFID tags can be reduced to about 15 cents in the next 1-2 years, and to 10 cents in 5 years. However, the electronic tag itself is not the only cost to be considered, and corresponding hardware and software investments are required to use the RFID system, which is also a huge one-time investment.

Through the improvement of integrated circuits, antennas and manufacturing processes, the cost of assembly of integrated circuits, antennas and other components and the cost of applying them to product packaging will be appropriately reduced. Although, there are still many technical obstacles to be resolved, such as strengthening the performance of semiconductor polymers, and substantial improvements and enhancements in printing resolution, registration accuracy, necessary isolation layers and a clean printing environment. However, it is believed that in the near future, the production cost of RFID and its electronic tags should soon drop to a price that merchants can generally accept.

2 Material factors

Many of the packaging products are liquid or the packaging material is metal. Liquid will absorb radio waves and metal will reflect radio waves. This makes it difficult for RFID to track products packed with high-content liquids, and products packed with metal or metal foil. This is also one of the factors restricting the application of electronic tags in the packaging field.

3 The effective range of the reader

The effective range of the reader largely depends on the frequency selected by the electronic tag. The direction of the tag also affects the effective range and accuracy of the reader. When the tag passes through the reader from a vertical state to a rotating tilt state, its reading range will be reduced. When a single label on the conveyor belt passes within the effective range of reading, the reading reliability and accuracy are very good, and the reliability of reading multiple labels on the conveyor belt with different directions cannot be guaranteed. The size of the tag and the reading antenna is also an important factor, and the reading distance of a handheld reader is much lower than that of a fixed reader, so it is only suitable for short-distance electronic tag reading.

4 Reliability and stability of radio waves

Anyone who uses a mobile phone has experienced the unpredictability of radio waves in transmission, and there will be signal weakening or interruption, and this situation will also appear in the transmission between RFID tags and RFID readers. When the radio wave is not stable, the RFID reader will not receive the signal from the RFID tag, which will cause the delay or loss of information. This also limits the application of RFID in the packaging field.

5 Interaction between electronic tags

RFID tags and RFID readers rely on radio waves to transfer information to each other, but if they encounter the influence and interference of electromagnetic waves and other RFID tags and RFID readers, the information will not be accurately transmitted. Because it is very likely that different RFID systems choose different frequencies, if there are RFID systems with different frequencies in the same area, their respective RFID systems will be interfered by another RFID system. This will also cause information loss and damage, so avoiding interference with the RFID system is also a problem that needs to be solved.

6 Interference of electromagnetic field

The interference of electromagnetic fields is ubiquitous, and many radio-based technologies can cause interference to the RFID system, causing many problems. Other factors in the environment, such as radio waves, mobile phones, local area networks, and neon lights will all produce electromagnetic field interference. This kind of interference will affect the accuracy of the production, correction and change of data in the entire supply chain during logistics management in the packaging field. Therefore, when choosing RFID technology, especially when considering cables and other communication facilities, it is necessary to focus on the problem of electromagnetic field interference. In order to find out whether there is such an interference problem, it is necessary to implement some test measures and solve them accordingly.

7 database management

A complete supply chain in physical management has potentially huge dynamic data and temporary data, which far exceeds the processing capabilities of current database management software. The use of RFID system is bound to be accompanied by a large amount of new data information. So far, many suppliers have not established a special database to collect and analyze this information, and based on the analysis to consider the next step, feedback to the supply chain for adjustment. Therefore, this is also a major factor that limits the large-scale application of RFID in the packaging field.

8 encoding compatibility

The RFID coding standard and communication protocol (communication interface) constitute the core of the RFID standard. At present, in the development of RFID technology, five major standards organizations have been formed: EPCglobal, ISO, UID, AIM and IP-x, representing the interests of different groups or countries in the country. The incompatibility of these standards and the incompatibility with the existing coding system will restrict the wide application of RFID.

9 kinds of wireless frequency characteristics

The frequency at which RFID tags and readers work is called RFID working frequency. At present, the frequency used by RFID spans multiple frequency bands such as low frequency (LF), high frequency (HF), ultra high frequency (UHF), and microwave. Various wireless frequencies have their own advantages and disadvantages. The choice of RFID frequency affects the distance and speed of signal transmission, and is also restricted by laws and regulations of various countries.

1O data sharing and privacy

During the implementation of RFID, privacy has become a universal concern. Many people are very upset about their actions and buying habits being automatically tracked. They think this is a matter of personal privacy. Of course, a company that implements RFID in its supply chain management absolutely does not want its opponents to track its goods and inventory. If the public does not have a sufficient sense of security in the protection of privacy, then the implementation of RFID will encounter great resistance.

In addition, there are also factors that need to be considered, such as the uniformity of RFID international standards and national standards, the protection of corporate internal information, and the printing methods and production of electronic labels.

[ad_2]