A bar code distribution and storage management system for a small household appliance industry

[ad_1]

The company is a manufacturer of small household appliances. The company purchases various accessories and manufactures them into finished products for sale. Before the implementation of the bar code system, the company’s warehouse procurement of accessories and finished product delivery were all manual document processing, which was relatively inefficient. Inventory errors and wrong shipments often occur, and management methods are relatively backward.

With the continuous expansion of production scale, the processing of warehouse receipt and delivery has become less and less able to keep up with the development of the company, and queues often occur to receive goods. In order to strengthen management control and improve the efficiency and accuracy of warehouse management, the leaders of the enterprise Decided to use bar code as a means of warehouse management, through the bar code to achieve accurate data operation and convenient enterprise invoicing system.

According to the actual needs of the company, we developed and implemented a bar code distribution and storage management system for the company on the basis of detailed investigation and continuous improvement of the plan. It has established a good platform, strictly controlled the warehouse items of the enterprise, clarified the accounts receivable and payable of the enterprise, improved the work efficiency of the enterprise, and achieved good investment benefits.

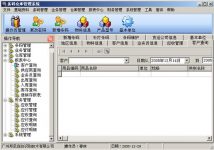

System operation interface:

The main operation interface, the system includes business management, warehouse management, report center, financial receivables and payables statistics, and system management modules.

Accessory storage interface.

Production order entry interface

Finished product warehousing interface

The company is a manufacturer of small household appliances. The company purchases various accessories and manufactures them into finished products for sale. Before the implementation of the bar code system, the company’s warehouse procurement of accessories and finished product delivery were all manual document processing, which was relatively inefficient. Inventory errors and wrong shipments often occur, and management methods are relatively backward.

With the continuous expansion of production scale, the processing of warehouse receipt and delivery has become less and less able to keep up with the development of the company, and queues often occur to receive goods. In order to strengthen management control and improve the efficiency and accuracy of warehouse management, the leaders of the enterprise Decided to use bar code as a means of warehouse management, through the bar code to achieve accurate data operation and convenient enterprise invoicing system.

According to the actual needs of the company, we developed and implemented a bar code distribution and storage management system for the company on the basis of detailed investigation and continuous improvement of the plan. It has established a good platform, strictly controlled the warehouse items of the enterprise, clarified the accounts receivable and payable of the enterprise, improved the work efficiency of the enterprise, and achieved good investment benefits.

System operation interface:

The main operation interface, the system includes business management, warehouse management, report center, financial receivables and payables statistics, and system management modules.

Accessory storage interface.

Production order entry interface

Finished product warehousing interface

Finished product delivery schedule

Inventory interface

accounts receivable

Accounts Payable

[ad_2]