Application analysis of RFID technology in automated storage yard

[ad_1]

With the rapid development of information technology, the port’s production and management technology has been greatly improved. The intelligent level of the automated bridge in the port yard has become an important label for improving the productivity of the terminal. Customs in various places focus on modern scientific and technological means, strive to build a new and convenient customs clearance mode, and do a good job of management and service in the import and export links.

Tyre cranes (hereinafter referred to as tyre cranes) occupy a larger proportion in global port yard bridge equipment, and rail-mounted cranes account for a smaller proportion. Therefore, the development of automated and intelligent green ports is inseparable from tire cranes. Similarly, the automatic transformation of tire cranes will play a positive role in promoting the automation and intelligence of green ports and port machinery manufacturing enterprises. Under the current container information management standard conditions, it combines modern computer technology, modern electronic technology, software engineering technology, database technology, and RFID technology to realize the high efficiency of data collection, automatic equipment control, and automatic business processing at the entrance crossing of the automated yard Yard system.

It is worth noting that RFID technology has its particularity. It is necessary to comprehensively consider the characteristics of on-site machinery and operating environment, actual use requirements, the realization concept of intelligent radio frequency technology and the overall operation function structure and other key links for planning and design. The gate system is used in conjunction and integrated into the terminal yard management. It is designed and implemented based on the structure and function of the entire production operation system. It is independent of other operation subsystems in the port, and there are many interactions and connections, and finally provides a function for the terminal. Complete, advanced equipment, convenient operation, safe and reliable, and economical investment in automation system integration solutions.

1. System design

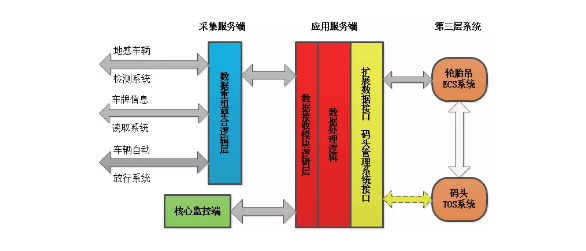

The RFID and barrier system architecture at the entrance of the terminal automated storage yard is designed as a three-tier architecture. The design idea of the three-tier architecture is based on the standardization of interfaces, which fully meets the scalability of the system and the flexibility of system composition.

System design ideas:

1. The equipment connection framework (including RFID reading and writing equipment, vehicle detectors, etc.) that provides system software and hardware standard interfaces, provides raw data for the production management system, and at the same time is responsible for the linkage control of the equipment. The system provides seamless integration and connection, and various devices can work normally and independently, and can also be coordinated and linked under the control of the system’s timing control logic.

2. Use modern advanced software engineering to provide information processing system architecture based on business processes, and reasonably standardize data flow. At the same time, it provides an easy-to-use, user-friendly client operating system. The design of the architecture complies with advancement, scalability, flexibility and standardization.

1.2 System design architecture

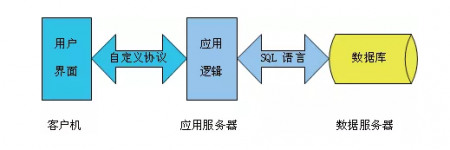

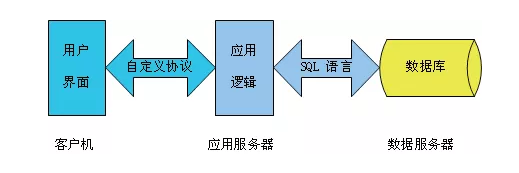

The intelligent storage yard RFID and barrier system structure is a three-tier architecture design, the first layer is the client (user interface), which provides friendly access between users and the system; the second layer is the application server, responsible for the realization of business logic; the third layer It is a data server, responsible for the storage, access and optimization of data information. Because the business logic is extracted to the application server, which greatly reduces the burden on the client, it is also called a thin client structure, as shown in the following figure.

1.3 Advantages of system architecture

The three-tier structure adds an application server to the traditional two-tier structure to process the application logic separately, so that the user interface and the application logic are located on different platforms, and the communication protocol between the two is defined by the system. Such a structural design allows the application logic to be shared by all users, which is the biggest difference between a two-tier structure application software and a three-tier application software.

First of all, by dividing the entire system into different logic blocks, the application system development and maintenance costs are greatly reduced. The three-tier structure separates the presentation part and the business logic part according to the client layer and the application server. The communication between the client and the application server, the application server and the database server, and the data exchange between heterogeneous platforms can all be through middleware or Relevant procedures to achieve. When the business logic of the database or application server changes, the client does not need to change, and vice versa, which greatly improves the reusability of system modules, shortens the development cycle, and reduces maintenance costs. Second, the scalability of the system is greatly enhanced. The modular system is easy to expand in both vertical and horizontal directions: on the one hand, the system can be upgraded to a larger and more powerful platform, and the scale can also be appropriately increased to enhance the network application of the system. Because it gets rid of the restriction of system isomorphism, it makes distributed data processing possible.

1.4 System architecture realization

The intelligent yard RFID automatic identification, the barrier system uses the identified vehicle information combined with the terminal operation management system to provide data comparison for the entry operation, dynamically provide operation information for the remote core control staff, and give alarms and various error messages. hint. For such a complex system, the adopted system design structure directly determines the stability, reliability and practicability of the system. The system design adopts a three-tier software system architecture, balances the resource utilization of the entire system by various hardware devices and related systems, optimizes system resources to the greatest extent, and makes the system flexible, convenient to use and maintain, operational stability, and good openness , Flexible scalability and hierarchical scalability.

2. System composition

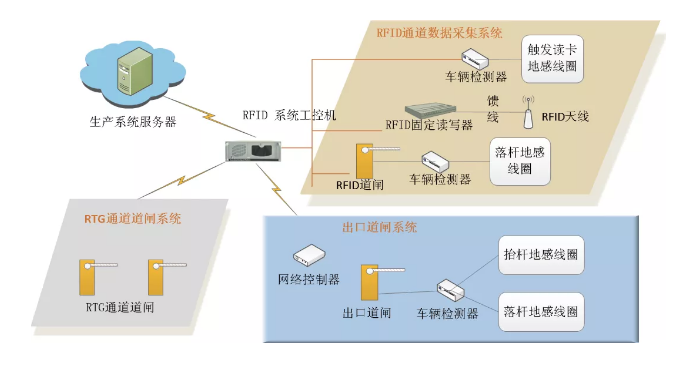

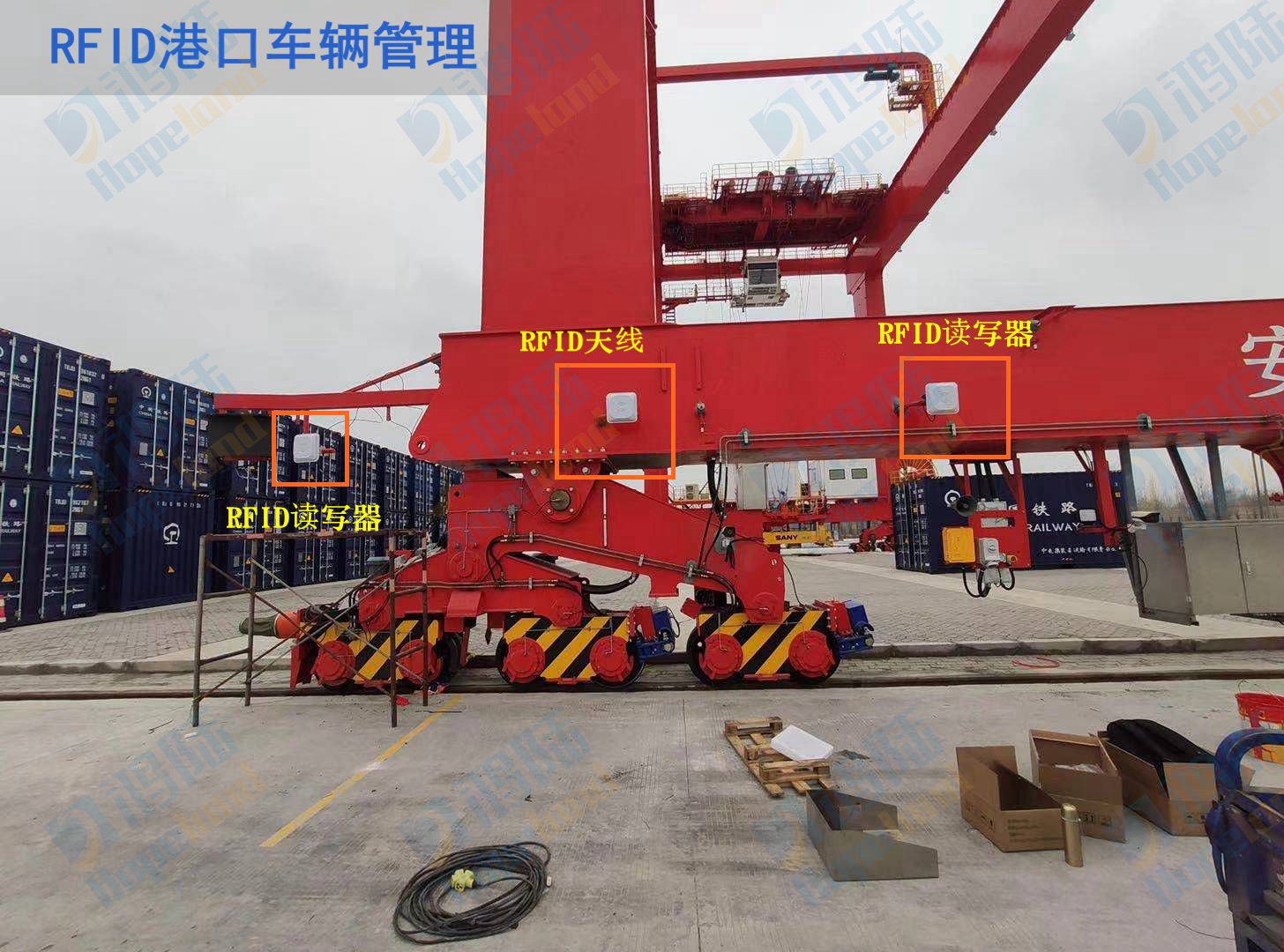

The terminal automation RTG yard RFID system consists of three parts: RFID data acquisition system, RTG channel barrier system, and exit barrier system.

2.1 RFID data acquisition system

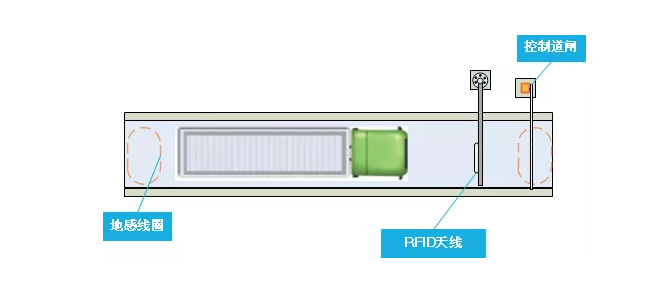

The RFID data acquisition system is composed of electronic license plates, UHF RFID readers, RFID antennas, embedded hosts, electromagnetic induction coils, and vehicle detectors. In the yard, the RFID crossing weak current box equipment is installed on the metal vertical pole at the crossing, the RFID antenna is installed on the door frame pole of the metal vertical pole, and the RFID card reader, industrial computer, network switch, vehicle detector and other equipment are installed in the equipment box. As shown in Figure 4. The RFID electronic tag is attached to the front windshield of the vehicle, and the card reading is triggered through the crossing.

2.2 RTG channel barrier system

When the RTG transitions, the remote control center needs to know that the RTG is leaving or entering another yard, and an RTG channel barrier system is set up for this. After receiving the movement instruction, the security personnel is responsible for opening the RTG channel barrier manually or through the wireless remote control. After the RTG is fully passed and safety is confirmed, then the on-site manual or wireless remote control is performed to close the channel by manually or wirelessly.

2.3 Vehicle exit barrier system

The main function of the vehicle exit barrier system is to restrict vehicles from entering the yard in reverse. It is composed of exit barriers, vehicle detectors, network control, and ground sensing coils. When the vehicle leaves the approaching exit, it triggers the lever-lifting ground sense, and the barrier lifts the bar to let it go. After exiting the channel and leaves the ground-bar fall sensor, the barrier automatically drops the bar. After the vehicle leaves the barrier and falls, the barrier system will send a vehicle departure signal to the remote control center in the port through the network controller, so that the background management system can count and count the vehicle operations. Reverse vehicles drive into the ground-induction coil barrier without lifting the rod.

3. Implementation effect

After the completion of the functional debugging and testing of the RFID and barrier system of the terminal yard, 4 automated tire cranes in 2 yards were put into use. The performance of the yard RFID and barrier system is stable, and the entire yard automation system is in good condition. The successful application of the system not only reduces the operating pressure of the operators in the remote control center of the automated tire crane, but also makes it clear that the trucks enter and exit the yard. Make the operation of the automatic scheduling system of the automatic tire crane more reasonable.

4. Conclusions and prospects

The system can not only realize RFID automatic identification of license plate numbers, and realize automatic operation verification during the operation of the port area, but also can control the rapid opening of the gates in the yard, which brings convenience to port management and efficient operation. The system hardware structure is simple, the investment cost is low, and it is easy to implement. It is very suitable for large container terminals with unmanned management in the container area, and has good industry promotion and use value.

[ad_2]