Application of RFID power transmission and transformation equipment life cycle management system

[ad_1]

1. System overview

There are gaps in responsibility in the management of power transmission and transformation equipment, and there are prominent problems in basic information and information processing and utilization. Power grid enterprises have put forward urgent requirements for establishing a full life cycle management (PLM) system for power transmission and transformation equipment. This system is based on RFID (Wireless Identification) technology,barcodeThe technology identifies and carries information for power transmission and transformation equipment; the system includes: procurement, operation, maintenance and scrapping management subsystems; the system integrates the asset management process of enterprise power transmission and transformation equipment, unifies data sources, and realizes procurement, operation, maintenance and scrapping The seamless integration of other businesses greatly improves the asset management efficiency and benefits of power transmission and transformation equipment.

2. Function introduction

◇ Integrate the entire power transmission and transformation equipment management process of the enterprise, unify the data source, and realize the seamless integration of all business links such as purchase, operation, maintenance and scrapping;

◇ Through the tracking and collection of life cycle information of power transmission and transformation equipment through the PLM (full life cycle management) system, the traceability of relevant information (suppliers, materials, batches, maintenance personnel) can be realized;

◇ Optimize the business process of power transmission and transformation equipment management to ensure accurate, timely and complete information;

◇ By implementing based onRFIDThe physical identification system can not only improve the existing asset management level but also greatly improve the asset utility, and can achieve the following results on the basis of the original manual operation:

※ Improve asset utilization by 10-20%;

※ Reduce asset operation risk by 10-15%;

※ Improve the actual performance of assets by 10%;

※ Reduce energy consumption by 10-15% to the greatest extent;

※ Reduce asset loss to 95-99%;

※ Improve material logistics efficiency by 15%; reduce material consumption loss by 10%. Especially in the following application areas, it is most obvious:

※ Reduce material consumption loss by 10%.

Especially in the following application areas, it is most obvious:

※ Significantly realize the consistency of accounts, cards and objects, shorten the asset inventory cycle by 80%, and reduce the error rate by 95%;

※ Significantly improve logistics efficiency, reduce material inventory by 15%-20%, reduce inventory cost by 15%, and improve logistics efficiency by 15%-25%;

※ Significantly improve the efficiency and error of project handover, shorten the project handover cycle by 60% and reduce errors by 99%;

※ Significantly improve the efficiency and cost of technical renovation and maintenance, increase the risk of operation guarantee by 10%-20%, reduce the cost of technical renovation by 10%, and reduce the operating cost by 15%.

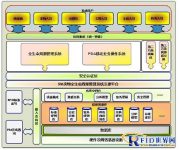

3. Application Technology Framework

4. Advantages and Features

◇ Rich experience in life cycle management, fully understand and meet the needs of users, provide more complete solutions, and form a systematic and complete quality and safety traceability management system. ◇ Professional power transmission and transformation equipment life cycle management, the system is powerful, stable in performance, reliable in quality, and has good scalability.

◇ The software system has uniformity, good expansibility, powerful functions, meets user needs, friendly interface, easy to learn and use, and has high cost performance.

◇ The software system adopts SOA architecture, so that enterprises can add new services or update existing services in a modular way to solve new business needs, provide options so that services can be provided through different channels, and can Or existing applications as a service, thereby protecting existing IT infrastructure investments. Adopt advanced RFID technology, large amount of information storage, RFID temperature, humidity and pressure sensors, resistant to low temperature environment;electronic labelIt has strong reading penetration performance, fast recognition speed and long recognition distance, strong anti-interference ability, and adapts to harsh environments; RFID handheld readers are light in weight, small in size, and easy to carry and use.V. Typical Case Guangdong Power Grid Corporation

◇ Adopt advanced RFID technology, large amount of information storage, RFID temperature, humidity and pressure sensors, low temperature environment; electronic tags have strong reading penetration performance, fast recognition speed and long recognition distance, strong anti-interference ability, and adapt to harsh environments; RFID The handheld reader is light in weight, small in size, and easy to carry and use.

5. Application cases

Guangdong Power Grid Corporation

[ad_2]