Description of successful application case of Jinwanma

[ad_1]

Oil (gas) industry application case description

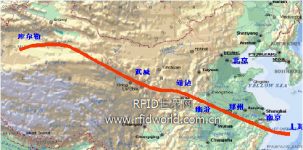

1. West-East Gas Transmission

Project Name: West-East Gas Pipeline Renovation and Reconstruction Project

Time of winning the bid: December 2005

Project Overview:

The West-East Natural Gas Pipeline traverses the east and west of my country. The starting point is Lunnan in Tarim, Xinjiang, and the end point is Baihe Town, a western suburb of Shanghai. The pipeline runs from west to east through Xinjiang, Gansu, Ningxia, Shaanxi, Shanxi, Henan, Anhui, Jiangsu and Shanghai. City and other 9 provinces (regions) and cities. The total length of the pipeline trunk line is about 3900km. In addition, three branch lines have been completed and put into operation at the same time, with a total length of about 350 kilometers. At present, there are six management offices on the whole line. From west to east, there are Xinjiang, Gansu, Ningshan, Shanxi, Henan, Anhui and Jiangsu, Zhejiang and Shanghai management offices, which are responsible for the operation and management of the main lines, branch lines and large and small craft stations.

Application:

There are six management offices in the West-East Gas Pipeline. Take the Henan-Anhui Management Office (Zhengzhou) as an example. The management office has 3 management teams, 12 transmission stations, and several line patrolmen. Each line inspector is equipped with a GPS inspection device, which adopts a fixed-point inspection method, and each transmission station is equipped with a remote communication cradle and system management software. The transmission station is responsible for data collection, query and statistics, and the management team is responsible for the management of the line patrollers in several transmission stations and the data summary and reporting. Taking the Dingyuan management team as an example, it is responsible for the management of the line patrol workers at the four transmission stations of Dingyuan, Chuzhou, Hefei and Liuxiangzi, and summarizes the data of the communication seats of the four stations every month and reports it to the management office . Each transmission station uses the cradle to collect the data of the line patroller’s GPS patrol device once a week and make statistics.

The Henan-Anhui Management Office of the West-East Gas Pipeline stipulates that the transmission station and the management team supervise each other, and each patrolman is responsible for patrolling 7-8 kilometers, 10 patrol points, and patrolling once a day. The data is uploaded once a week, and the management team reports once a month.

solved problem:

1. The inspection management system has indeed solved the inspection rate of line workers.

2. Simple construction and maintenance, flexible change of information points.

3. The inspection device is easy to operate, and the data upload is convenient and fast.

4. Added management means to achieve the purpose of maintenance and management.

Taking the Dingyuan maintenance team as an example, during the trial operation stage of the system, a line patrolman discovered that there was an external force construction in his inspection section, and reported it in time to eliminate hidden dangers. Only 1 meter away.

In general, the GPS inspection management system has added inspection management means, which is imperative.

2. Western Pipeline

Project Name: Western Pipeline GPS Patrol Management System

Time of winning the bid: January 2007

Project Overview:

The total length of the western pipeline project is 4,000 kilometers, including two large-diameter pipelines laid in the same ditch for crude oil and refined oil, and the construction of several stations and warehouses. The starting point of the pipeline is Urumqi, Xinjiang, and the main counties and cities are Turpan, Shanshan, Hami, Anxi, Yumen, Jiayuguan, Jiuquan, Gaotai, Linze, Zhangye, Shandan, Yongchang, Wuwei, Gulang, Tianzhu, Jingtai, Yongdeng, Gaolan, and finally Lanzhou last station in Lanzhou. Among them, the trunk line of crude oil pipeline is 1,546 kilometers long, and the trunk line of refined oil pipeline is 1,842 kilometers long, with a total of 13 stations.

Application:

The western pipeline has two branches in Xinjiang and Lanzhou, four operation areas and 13 transmission stations. The Lanzhou branch has two operation areas, and the two operation areas have a total of 7 transmission stations, which are inspected according to the trajectory. The patrol device will automatically record the patrolling track of the line patrolmen, and transmit the track information in real time to the Western Pipeline Management Center through the GSM network. The management center can keep abreast of the work status of each line patrolman at any time.

solved problem

1. Through the management center in Xinjiang, complete the setting of each inspection line, inspection section and inspection point of the pipeline, and deploy the inspection tasks of maintenance personnel.

2. Real-time viewing and review of the inspection routes of the inspectors in the management center, assessing the work of the inspectors, and achieving the purpose of centralized management.

3. Check the pipeline line resource data to obtain more scientific inspection resource data.

4. The query of inspection data and the management of inspection personnel are localized.

5. The inspection data is uploaded to the database of the management center for centralized management and maintenance, and a work report for pipeline inspection can be formed.

3. Zhongcang Gas Pipeline

Project Name: GPS Patrol System for Zhongyuan Oil and Gas Pipeline Project

Time of winning the bid: August 2006

Application:

Zhongyuan Oilfield to Cangzhou Gas Pipeline (Zhongcang Line) is a special gas pipeline, which passes through Henan Puyang, Shandong Xinxian, Liaocheng, Chiping, Gaotang, Pingyuan, Dezhou, Hebei Wuqiao, Dongguang, Nanpi, There are twelve counties (cities) in three provinces, Cang County and Cangzhou, with a total length of 361km. There are three large stations and seven small stations in the Zhongcang Gas Pipeline for hierarchical management. Each patrol line is equipped with a GPS inspection device, which adopts the method of fixed-point inspection. There are more than 400 inspection points along the line. Each line patrolman is responsible for about 8 kilometers of pipelines and patrols once a day. Every time you go to an inspection location, the handheld device will automatically record the name of the location and the time of arrival. After the inspection, the inspection data will be uploaded to the pipeline center through the remote cradle.

solved problem:

1. The inspection management system has indeed solved the inspection rate of line workers.

2. Simple construction and maintenance, flexible change of information points.

3. The operation is simple, and the data upload is convenient and fast.

4. Added management methods to achieve the purpose of maintenance and management, and avoid the occurrence of such incidents as drilling holes, stealing air, and illegal occupation.

4. Shengli Oilfield and Henan Oilfield

Project name: Shengli Oilfield, Henan Oilfield Production Inspection Online Management System

Time of winning the bid: June 2006 (Shengli Oilfield), March 2008 (Henan Oilfield)

Application:

It has fully realized the electronic monitoring of oil pipelines, oil production equipment, and oil well production, and the tracking and display of the inspection trajectories of inspection personnel. The level of forecasting and control of work efficiency.

solved problem:

• Completely get rid of the disadvantage that the inspection information is not transmitted in time, and the dispatcher cannot monitor the inspection process.

• Realize the electronic and informatization of inspection work.

• Effectively reduce the problem of missed detection caused by human factors.

• Enable the production management to effectively supervise the work status of the inspectors.

• Realize the automatic alarm function of inspection fault information and emergency information.

Mobile industry application case description

1. Guizhou Mobile

Project name: GPS inspection project of primary and secondary trunk optical cables in Guizhou Province

Time of winning the bid: Phase I project: February 2006, Phase II project: March 2007

Project Overview:

The primary and secondary trunk optical cable transmission network in Guizhou Province passes through Guiyang, Zunyi, Anshun, Duyun, Kaili, Bijie, Tongren, Liupanshui, Qiandongnan, Qianxinan and other prefectures along the way, with a total length of 3,200 kilometers.

Application:

Every 40 kilometers is an inspection section, during which there are more than 100 designated inspection points (one inspection point is set at 300-500 meters); The line is inspected and is responsible for the corresponding inspection section. Different inspection plans can be formulated for different inspection sections, such as 3 times a month or 1 time a week. The inspector should complete the inspection within the designated time period, and arrive at the designated inspection road section and each inspection point by foot or vehicle inspection.

solved problem:

1. Through the control center in Guiyang City, set up inspection points and inspection sections in various cities along the route of the trunk optical cable. And deploy the inspection tasks of the maintenance companies in various cities.

2. Realize real-time monitoring of inspectors in prefectures and cities and on behalf of maintenance units to achieve the purpose of centralized management.

3. Check the optical cable line resource data to obtain more scientific inspection resource data.

4. All cities can summarize the inspection data, conduct inspection inspections, and provide various transmission line inspection work reports to Guiyang city center.

2. Shandong Qingdao Mobile

Project Name: Shandong Mobile Qingdao Area GPS Optical Cable Inspection Project

Time of winning the bid: August 2005

Application:

With each Qingdao as the center and each county as the unit, the inspection road sections are divided, and the track inspection method is adopted. The inspection personnel of each county are divided into the above-mentioned transmission lines to inspect the above-mentioned transmission lines and are responsible for the corresponding inspection sections. The inspector needs to complete the inspection within the designated time period, and arrive at the designated inspection road section and each inspection point by foot or vehicle inspection.

solved problem:

1. Through the control center located in Qingdao, set up inspection points and inspection sections in the counties along the optical cable. Deploy the inspection tasks of the maintenance companies in each county.

2. Realize the real-time monitoring of the inspectors of the maintenance units in each county to achieve the purpose of centralized management.

3. Check the optical cable line resource data to obtain more scientific inspection resource data.

4. Each county can summarize the inspection data, conduct inspection inspection, and provide Qingdao Center with various transmission line inspection work reports.

3. Hubei Wuhan, Huanggang and Ezhou Mobile

Project name: Hubei Mobile’s GPS fiber optic cable inspection project in Wuhan, Huanggang, and Ezhou areas

Time of winning the bid: January 2007 (Wuhan) July 2006 (Huanggang) March 2006 (Ezhou)

Application:

More than 400 kilometers of optical transmission cables are inspected by the inspectors, who are responsible for the corresponding inspection sections. Different inspection plans can be formulated for different inspection sections, such as 2 times a week. The inspector needs to complete the inspection within the designated time period, and arrive at the designated inspection road section and each inspection point by foot or vehicle inspection.

solved problem:

1. Through the management terminal of the control center, set the inspection points, inspection sections and inspection lines along the route of the optical cable. Deploy the inspection tasks of each generation and maintenance company.

2. Realize the real-time monitoring of the inspectors of the maintenance agency to achieve the purpose of centralized management.

3. Check the optical cable line resource data to obtain more scientific inspection resource data.

4. It can summarize inspection data, conduct inspection inspection, and provide various transmission line inspection work reports.

4. Bijie, Zunyi, Tongren Mobile in Guizhou

Project Name: GPS Optical Cable Inspection Project in Bijie, Zunyi, Tongren, Guizhou Province

Time for winning the bid: May 2007 (Bijie), June 2008 (Zunyi), November 2008 (Tongren)

Application:

With each city as the center and the county as the unit, the inspection section is divided, and the fixed-point inspection method is adopted. 2-3 inspection fixed points are set per kilometer, and inspection points are added at the base station; The division of labor conducts inspections on the above-mentioned transmission lines, and is responsible for the corresponding inspection sections. Different inspection plans can be formulated for different inspection sections, such as once a week. The inspector needs to complete the inspection within the designated time period, and arrive at the designated inspection line and each inspection point by foot or vehicle inspection.

solved problem:

1. Through the management terminal of the control center located in the city, set up the inspection points, inspection sections and inspection lines of the counties along the optical cable. Deploy the inspection tasks of the maintenance companies in each county.

2. Realize the real-time monitoring of the inspectors of the maintenance units in each county to achieve the purpose of centralized management.

3. Check the optical cable line resource data to obtain more scientific inspection resource data.

4. Each county can summarize the inspection data, conduct inspections, and provide various transmission line inspection reports to the city center.

Power industry application case description

1. Xinyang Branch of Henan Electric Power Company

Project Name: GPS Inspection Management System for Power Lines in Xinyang Line Work Area

Time of winning the bid: January 2008

Project Overview:

The Line Work Area of Xinyang Electric Power Company has jurisdiction over more than 50 high-voltage lines in 8 counties and 2 districts, with a total length of more than 6,000 kilometers and the management and maintenance of more than 3,000 power towers.

Each high-voltage power line is inspected by nearly 100 inspectors from each team in the work area. Different inspection plans can be formulated for different inspection sections, such as once a month or once a week. The inspector should complete the inspection within the designated time period, and reach the designated inspection section by foot or vehicle inspection.

Application:

Using the longitude and latitude coordinates collected by GPS, the GIS geographic information layer can be dynamically generated to display the route map. At the same time, the line length can be calculated according to the longitude and latitude information of the towers uploaded by the GPS inspection equipment, and the number of towers and the distance from the two-way substation can be calculated according to the positioning information. According to the type of poles and towers entered, the number of iron towers, the number of tension towers, the number of linear towers, the number of cement poles, the number of tension poles, and the number of linear poles can be automatically determined. These data are changed according to the positioning information. When the line is changed due to technical renovation or reconstruction, the data will be automatically updated as long as the relocation data is relocated. And show the new route map and route road map in GIS.

The tower database can record monthly inspection records, uploaded by the GPS inspection equipment, and count the tower defect records according to the monthly inspection records. The tower type is determined by data, the distance is converted from latitude and longitude data, the drawing is called from the route drawing, and other data is determined by the height. , Tensile section length, salt density, insulator inspection, wire connector measurement, special inspection inspection, video data, crossover measurement, grounding resistance measurement, tower tilt measurement, concrete pole crack inspection, steel strand and buried metal parts corrosion Inspection, overhaul and maintenance, external hidden danger processing, channel processing, equipment change data screening and generation.

According to the line defects collected by the GPS line inspection equipment every month, combined with the input basic data of the power line and dynamic data such as line maintenance records and equipment change records, the real-time operation data of the power line is generated. The combination of GIS, GPS and power line data management makes the line operation management, maintenance management, data preservation and query trinity to form a complete, efficient and practical new model.

Statistical query part sorts, counts, inquires, and prints the operation, measurement, inspection, and maintenance table data of the tower data part by line after summarizing them.

The above content constitutes the operation data of the whole line, which is classified, counted and printed according to the line. The relevant information is associated with the database under the line name. Provide a reliable, real and effective basis for the safe and reliable operation and condition maintenance of the line.

solved problem:

1. Through the management center located in Xinyang, all levels of tower sections and inspection lines can be set up, and the inspection tasks of power lines at all levels can be deployed.

2. Realize the monitoring of inspectors and achieve the purpose of centralized management.

3. Check the power line resource data to obtain more scientific inspection resource data.

4. It can be combined with the MIS system in the power system to conduct inspection inspections, and provide various line inspection work reports to the upper-level center.

Public security industry application case description

1. Qingdao Public Security

Project name: GPS patrol inspection project of police vehicles in Laoshan District, Qingdao

Time of winning the bid: May 2007

Project Overview:

Public security management and inspection and maintenance of scenic routes in Laoshan area of Qingdao.

Application:

The police vehicles in Laoshan District will patrol and inspect the above-mentioned scenic routes, and are responsible for the corresponding inspection areas. For the inspection method of fixed locations (streets, intersections, etc.), data is transmitted to the management center through the GSM/GPRS network, and the management center formulates different inspection plans for different inspection areas, such as once a day, or 2-3 times a day inferior. The inspection personnel arrive at the designated inspection points through the vehicle inspection, and complete the inspection within the designated time period.

solved problem

1. Through the control command and management center located in Laoshan District, the patrol vehicles and patrol personnel are constantly monitored to achieve the purpose of centralized management.

2. The movement trajectory of inspection vehicles and patrol personnel is automatically tracked, and the alarm information is uploaded in time.

3. The control command management center is linked with 110 and 120.

4. Obtain more scientific inspection data information, which can be summarized and inspected for inspection.

Company Profile:

Jinwanma High-tech Development Co., Ltd., established in 1998, specializes in the research and development and production of automatic identification technology and products. It is a high-tech enterprise with automatic identification technology as the core, an overseas student entrepreneurial enterprise, and an ISO9001 certified enterprise. Products cover: contact inspection series, induction inspection series, GPS inspection system, GPS vehicle tracking system, GPRS/GSM/GIS system application, remote communication terminal, wireless communication terminal, etc.; provide industry solutions, products can be based on Users need secondary development. Products are widely used in community patrols, property patrols, railway patrols, oil pipeline patrols, telecom mobile optical cable patrols, power patrols, public security patrols, forestry patrols, logistics vehicle tracking management and other industries, and are exported The United States, Canada, Portugal, the Netherlands, France, Brazil, Chile, India, Thailand, Malaysia, Hong Kong, Taiwan and other dozens of countries and regions. The company’s products have passed the quality inspection of the State Bureau of Quality and Technical Supervision, the police electronic quality inspection of the Ministry of Public Security and the explosion-proof inspection of the Ministry of Chemical Industry, and a number of scientific research achievements have obtained national patents.

The company has set up branches in Beijing, Shenzhen, Shanghai and other places, and has established a complete marketing network and a strong after-sales service system in 26 provinces, autonomous regions and municipalities in China.

development concept

“Keep pace with the times and create a better future”

——It is our basic idea to develop domestic and foreign markets;

“Integrity and truth-seeking”

——It is the basic principle for us to maintain a good cooperative relationship with new and old customers;

“Technology is productivity”

——It is the basic guidance for us to develop new products from a high starting point;

“Quality is life”

——It is the basic idea of our strict quality control;

“Development Channel Partners”

– is the basic line of our business;

Service philosophy

Let users be 100% satisfied and 100% assured!

Your trust is our mission, and we look forward to cooperating with you to jointly grasp today and create the future together.

[ad_2]