Every roll of paper has a memory chip! RFID helps paper roll conveyor line management

[ad_1]

The management of the paper roll conveying line involves a series of processes such as the storage of the paper warehouse, the selection of raw paper, the inspection of the input into the warehouse, the roll into the warehouse, and the return of the residual roll after use. With the fierce market competition, base paper accounts for 70% to 80% of the production cost of paperboard, or even higher. Therefore, to do a good job in paper roll management, every 1% to 2% reduction in the loss of base paper by enterprises means an improvement in production and operation efficiency.

Current status of traditional paper roll management:

At present, the management of warehouse paper rolls is to indicate the specific parameters by hand on the outside of the original paper tube. It is easy to cause the handwritten parameters to fall off in the conveying line, and the weighing measurement needs to be re-measured, which leads to the reduction of work efficiency and the waste of labor costs. With the increase in the degree of refinement of production, cracking and softening of the base paper are prone to occur due to the seasonal change of the base paper, which has higher requirements for the information management of the base paper.

The specific process of RFID paper roll conveyor line management:

1. The original paper is weighed, and the information of the paper roll is entered into the RFID electronic tag, and then the UHF RFID tag is inserted into the original paper core tube, and stored in the warehouse;

2. During the production conveyor line, the forklift lifts the paper out of the warehouse, no need to scan again, put the paper roll to the designated position, can automatically identify the relevant information of the paper roll, and transport it to the corresponding station;

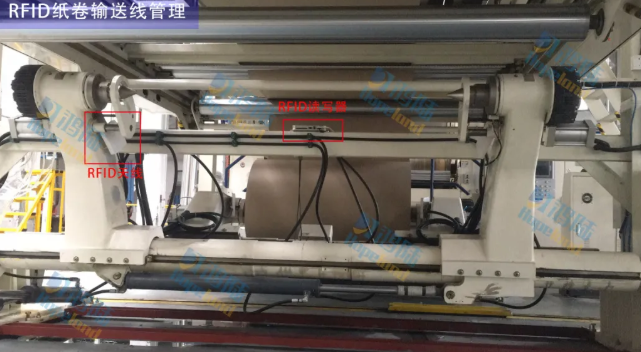

3. When the paper roll reaches the corresponding paper shelf, the Honglu RFID reader on the paper shelf can automatically read the relevant information of the paper roll and monitor the use of the paper roll throughout the process;

4. The remaining weight (long meters) of the paper roll is automatically recorded after it is removed from the shelf. There is no need to manually record the weight of the original paper. The paper head is directly returned to the warehouse without weighing and recording, which greatly saves labor;

5. Use the computer to query the data information of orders and paper rolls, and generate a variety of data statistics forms.

Through RFID paper roll conveyor line management, companies can predict purchases through paper roll inventory and business demand, and establish complete monthly/quarterly purchasing plans and standards. Then evaluate the quality of the base paper according to the market report to grade and rank the suppliers, and control the quality of the base paper from the source. Procurement is predicted based on the inventory of paper rolls, that is, the demand for raw paper procurement is judged by the stock turnover rate of the raw paper. RFID paper roll conveying line management effectively controls the stock of raw paper and reduces unnecessary losses due to human error; the same paper roll door width combing and regular cleaning of residual rolls have greatly improved the reduction of raw paper loss.

[ad_2]