Install the RFID chip on the tool holder-intelligent tool information management

[ad_1]

Numerical control machine tools have become the mainstream equipment in mechanical processing workshops. Generally, small-scale numerical control processing workshops have as many as thousands of tools, plus its supporting parts, totaling tens of thousands and hundreds of varieties. With the sharp increase in the number and types of tools, standard and non-standard tools of various types and specifications coexist in the production workshop, and a large number of tools frequently flow and exchange between the tool warehouse and machine tools and machine tools. At present, domestic processing workshops mostly rely on manual methods and paper bar codes to manage tools. Paper barcodes are easily stained in an oily environment, and tool life can only be judged by experience. Due to lack of tools, many machining processes are stopped, and machine tool operators need to spend a lot of time looking for tools. With the increase in the types of CNC machine tools and the types of new products, the existing tool management solutions can no longer meet the demand, so radio frequency technology (RFID) is introduced.

RFID is a non-contact automatic identification technology that emerged in the 1990s. It has fast scanning, small size, anti-pollution ability and strong durability, reusability, penetrating and barrier-free reading, large data memory capacity and safety It has strong characteristics, so it has huge application potential in production data collection, monitoring, and data transmission. This article is based on radio frequency technology, installs the RFID chip on the tool handle, realizes the collection and management of tool information, and reduces the comprehensive production cost.

1 Current status and needs of the tool management industry

Experts engaged in tool management research at home and abroad have developed many tool management software, but they cannot meet all the requirements of tool management. The existing tool management has the following problems:

①It is not possible to analyze the records and data of the entire life cycle of the tool, but to realize the collection and monitoring of tool information at the point in time, and it is impossible to obtain the unprocessed data;

②Traditional tool management lacks M2M (Machine to Machine) information interaction and cannot realize integrated management;

③The existing tool management plan is aimed at meeting production needs, and the cost of the tool throughout its life cycle is not considered.

In order to solve the above problems and achieve the goal of more intelligent automation in the manufacturing industry, it is urgent to introduce new technical means to manage tool information. In the process of precision machining of mobile phone components, Jinsheng Precision Components Co., Ltd. intelligently manages the use of tools in the machine tool, and transmits tool parameters to the machine tool, so that the tool is added to the machine tool magazine for the processing program to call. When the tool processing is completed, the production time of the tool is written into the RFID of the tool to realize the functions of real-time tool information collection and tool status tracking.

2 Tool information management system parameter collection and setting

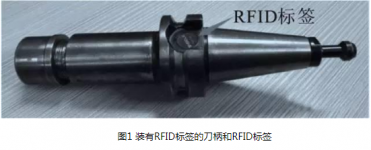

The tool information management system refers to the use of radio frequency technology, CNC and RFID readers to adopt serial communication technology based on the communication between the machine equipment (such as CNC machine tools, tool setting instruments, etc.) and RFID readers in the manufacturing unit. Realize the information monitoring and storage management of the tool in its life cycle. The entire life cycle of a tool generally includes planning, purchasing, marking, warehousing, lending, assembling, using, returning, regrinding, scrapping, etc. This article uses a tool designed by Sygole, with an RFID tag installed on the handle. The handle is shown in Figure 1. The time for RFID to read and write the tag is 500ms.

The prerequisite for the tool management of the machine tool is that the tool has been grouped, and the tool has been set by the tool setter. In order to realize the corresponding functions of the tool, the machine tool needs to initialize the tool magazine and write the tool processing time into the tool holder RFID. Because the reading and writing distance of high-frequency RFID is relatively short, when reading and writing the RFID of the tool holder, the antenna must be close to the RFID tag through a pneumatic device.

(1) Initialization of the machine tool magazine

To realize the intelligent transmission of CNC tool information, we must first rely on CNC machine tools. In order to ensure that the tool is automatically loaded into the tool magazine when the tool is loaded into the machine tool, and the tool parameters are read from the RFID tag into the machine tool magazine, the machine tool magazine needs to be initialized. The specific process is described as follows:

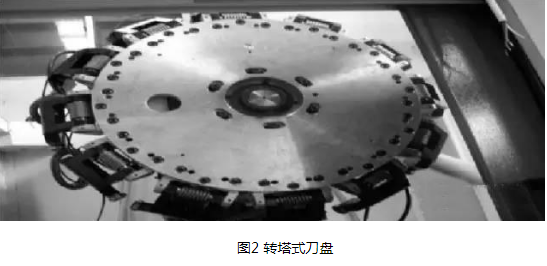

① When the machine tool changes, the machine tool needs to control the cutter head to rotate one week (see Figure 2), and reinitialize all the tools to the machine tool magazine;

②For each tool, the following operations are required: CNC drives the cylinder to lift the RFID reading head through instructions. After the cylinder is in place, the CNC obtains the status of the induction switch and starts the RFID reader; the cylinder status is maintained for 500ms, and the CNC drives the RFID reading through serial communication The writer reads the RFID chip of the tool holder; retracts the cylinder, and the CNC detects that the cylinder magnetic induction switch is in place, and the tool continues to run;

③Functions that need to be controlled: add a button to the CNC operation interface, and the cutter head will automatically rotate one circle each time the button is pressed to ensure that the tool can rotate one circle each time the tool is changed, and the machine tool magazine is initialized; it is not allowed to install the tool directly on the machine tool. Library tool handle.

(2) Tool production time record

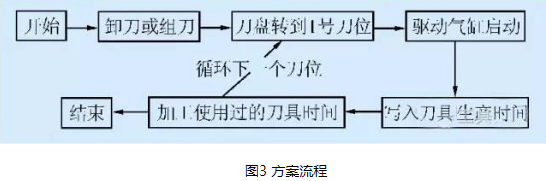

When unloading (group) the tool, the tool production (processing time) will be written into the tool management system. The process of writing the machining time of the machine tool into the RFID of the tool holder is as follows:

①Before the machine tool unloads the tool or after the tool is assembled, the machine tool records the used tools, rotates the cutter head, and writes the tool processing time one by one;

②The cylinder state is maintained for 500ms, and the CNC drives the RFID reader through serial communication and writes the RFID chip of the tool holder;

③Retract the cylinder, CNC detects that the cylinder magnetic induction switch is in place, and the cutter head continues to rotate.

To ensure the smooth operation of the above program, a button needs to be added to the CNC operation interface. Before unloading the tool or after grouping the tools, press the button once to make the machine tool rotate one circle and write the tool usage time to finally complete the tool life control. Pay attention to the operating specifications when operating the program flow. The program process is shown in Figure 3.

(3) Tool data storage in RFID chip

Tool code is the important information to determine the uniqueness of the tool’s identity. It is written into RFID, and each tool is managed through the tool code. When writing the corresponding program, the nominal diameter, nominal length and corresponding program of the tool can be determined according to the specification and model of the tool, and then the corresponding diameter compensation and length compensation can be given according to the actual situation. Since the same tool can be installed on different machine tools, and the same machine tool can process different products, abnormalities may also occur when processing products, so the above processing information needs to be displayed during processing. It can be controlled by the program to display the tool code, processed products, product quantity, abnormal information, etc., and the tool code, tool life, tool used time and other information in the RFID record.

3 Hardware system composition and software development

The hardware consists of electronic tags (RFID), antennas, readers and related data interfaces (see Figure 4). The RFID tag is a data carrier, composed of a chip and a coupling element. Each RFID tag has a unique electronic code; the RFID tag antenna is the transponder antenna of the RFID electronic tag, which transmits the radio frequency between the tag and the controller through communication induction Signal, reader is a device used to read or write RFID tag information.

summary

By installing RFID tags on the tools for life identification and information reading and writing throughout the life cycle of the tools, install readers on the host of equipment such as CNC machine tools, as the information interaction interface between the RFID tag and the main control system, and use the RFID tag as The information carrier realizes the information interaction between the tool and the host and the host and the host to realize the prediction of the tool life. The new solution can realize tool life management, reduce tool inventory by 20%, reduce tool cost by 10%, reduce preparation time by 15%, improve equipment efficiency by 10%, shorten delivery time by 10%, and reduce overall cost by more than 15%.

[ad_2]