Museum Collection Exhibit Management Solutions

[ad_1]

Status quo of fish collection management in Shanghai Science and Technology Museum

There are more than 700 species of fish specimens in the collection room of the Shanghai Science and Technology Museum, among which there are more than 200 species of fish specimens in the showcase, and about 500 species of fish specimens stored in the airtight room but not in the showcase. The airtight chamber is composed of airtight cabinets, and its shell is made of metal, and the depth of each airtight cabinet is about 1.2 meters. The showcase is made of glass, and the placement of fish specimens in the showcase is based on aesthetic considerations. At the same time, because the display cabinets are connected, some specimens will appear in a series of cabinets. At present, the Shanghai Science and Technology Museum has not established a database of fish specimens, and only stores the relevant information of fish specimens through a simple ECXEL form. The management of fish collections in the Shanghai Science and Technology Museum is based on traditional management methods. The entry and exit of collections need to rely on a lot of human labor. The inventory also requires manpower to check the accounts and the physical objects one by one, which not only wastes human and material resources, but also wastes financial resources.

System Overview

The information on the storage location of the collection can also make it easy for managers to check the specific location of the collection, find out the unreasonable situation and make corrections in time. With the powerful statistical function of the computer, the query and statistical work that the entire department used to complete in a few days can be completed in a few seconds. It is also very convenient to modify and supplement the data. Multiple data can be modified and supplemented and automatically synthesized by the computer to form new data. Using RFID technology for information management, establishing its own collection management system, assigning electronic tags to the fish specimens on display, and recording their detailed information, will make the data management basically say goodbye to the era of paper and pen and ink records, not only saving a large number of printing various Forms, cards, registration forms, account books and office expenses, and freeing warehouse managers from tedious and repetitive data management, and focusing their energy on physical management of collections, collection protection and collection research. In addition, the management of collections through FRID technology can also reduce the labor intensity of collections in, out of storage and inventory, and improve operational efficiency and accuracy.

System realization function

Specimen classification management

Assign different FRID tags to the fish specimens on display and record their detailed information. The specimens are classified according to family, sea area and age, and different types are placed in different showcases. At the same time, the placement of specimens in the same showcase should be based on aesthetic considerations. In this way, specimen managers can inquire according to the classification standards (family, sea area, etc.), which not only makes the specimens more scientifically classified and stored, but also improves the efficiency of the staff.

Inbound and outbound management

A 915 read head is set up at the door. When the fish specimen with a unique RFID passes through the door, the read head will scan all the tags, and the program interface of the warehouse management will appear on the display on the wall at the door, including all the items to be entered and exited. Specimen information in the library, and at the same time, you can select the operation of entering and leaving the library and the reason for selecting the entry and exit (new product storage, collection return, collection loan, collection exhibition, etc.) and so on. After a series of in-out operations are completed and checked, the in-out information of this time can be transmitted to the back-end database server through the network. In addition, when the reader at the door reads the label information, there will be a signal (such as flashing lights or voice prompts) to prompt the staff to perform operations related to entering and leaving the warehouse. After the work is completed, the light will disappear automatically.

inventory management

The glass cabinets are numbered, RFID tags indicating the cabinet number are attached, and the specimens are divided into different cabinet numbers. When taking inventory, the staff holds an RFID reader, scans the cabinet number first, and then scans the collections in the cabinet. The hand-held RFID reader will display the tag information read this time. After the staff confirms, the inventory data will enter the database in the background through the network. The staff take stock in turn. When the inventory of all cabinets is completed, the staff can query and print out the difference table of the inventory count and the calculated inventory number from the computer terminal. If there is an inventory gain or inventory loss, the staff can review the inventory or manually adjust the existing inventory.

System functions

The exhibition area will be comprehensively renovated and renovated to improve the educational concept and display level as a whole.

The target audience is preschool children aged 3 to 6 years old. Based on child psychology, according to the unique psychology, behavioral characteristics and educational methods of the target children, we plan and design exhibits that conform to the physical and psychological characteristics of children.

Through hands-on display projects and activities, children’s natural cognition and scientific cognition are expanded, and children’s potential in sensory, artistic, emotional, social and other aspects is inspired.

Calculated inventory: period-end data calculated from the beginning and inbound and outbound data.

Counts: The number of tags scanned with a handheld RFID reader.

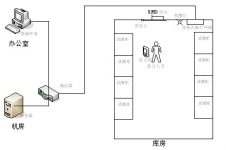

The overall structure of the system

The overall process of the system: the server, the query terminal, the router and the terminal operating machine are respectively connected in a wired form. When the specimens are put in and out of the warehouse on the terminal operating machine, the in-out information will be automatically uploaded to the server, and the staff can query through the inquiry terminal. Inbound and outbound information of outbound specimens. The handheld inventory machine is wirelessly connected to the server. During the inventory work, the inventory information scanned by the handheld inventory machine will be transmitted to the server in real time, and the staff can also obtain the inventory information of the specimen by querying the terminal.

[ad_2]