RFID construction goods storage technology makes management easier

[ad_1]

The city is developing rapidly, and construction has become a very important part. The development of construction project management is extremely rapid, combined with scientific and technological means, the requirements of construction projects are getting higher and higher. The management of various project information and building materials also adopts high technology. RFID building materials storage technology mainly uses RFID technology. Each material is affixed with electronic tags to identify the attributes of materials. In the process of material warehouse management, physical materials are used It is characterized by management to improve the efficiency and accuracy of warehousing, outgoing, and inventory management, mainly using RFID technology for intelligent collection, real-time update of the database, and RFID tags to trace the use of materials in the construction industry To ensure that the company can accurately manage the entry and exit of the material warehouse and inventory control, prevent the unknown loss and damage of the material without being traced, and solve the problem of inconsistency between financial data and physical conditions. Help building materials realize modern scientific, safe and reliable building materials management. RFID construction goods storage technology makes management easier.

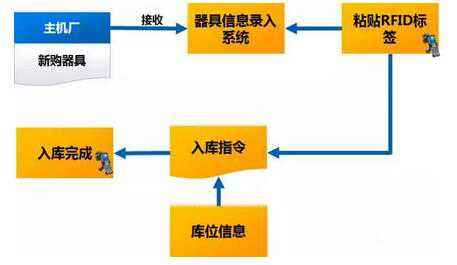

Attach RFID electronic tags to each item of materials, and choose the ones that can be reused for a long time and are suitable for harsh environments. Materials with RFID electronic tags are equivalent to assigning an ID card to each material. When the materials are in and out of management, they can be fixed or hand-held to collect information, and the label of each material is unique. There is no need to manually register in and out of the warehouse, and it is automatically recorded. The information of the asset owner is automatically associated when the materials are registered. When the equipment is illegally carried out, the system will automatically alarm.

RFID construction item warehousing technology carries out sorting and processing, and carries out out-of-warehouse management. If the quantity out of the warehouse is large, push the goods to the door of the warehouse in batches, use a fixed reader to communicate with the tags, collect the RFID electronic tags of the goods out of the warehouse, and check whether they correspond to the plan. If there are errors, manually as soon as possible deal with. For a small amount of goods, RFID handheld terminals can be used to collect information from RFID electronic tags (handheld scanners or RFID tablet computers). When an error occurs, an alarm will be issued, and the staff should deal with it in time, and finally send the data to the management center Update the database to complete the delivery.

RFID technology quickly carries out warehouse management. In accordance with the requirements of warehouse management, carry out regular and irregular inventory. When there is an inventory plan, use the RFID handheld terminal to scan the inventory. The information of the inventory can be transmitted to the back-end database through the wireless network and compared with the information in the database to generate the difference information and display it in real time. On the RFID handheld terminal, it is provided to the inventory staff for verification. After the inventory is completed, the inventory information is checked with the database information in the background, and the inventory is completed. In the inventory process, the system uses RFID non-contact reading to read clothing goods information very quickly and conveniently. Compared with the traditional model, it will improve a lot of efficiency and inventory accuracy.

Fully consider the scalability and security of the system, and provide reasonable tools to ensure system security. System management mainly completes the correction and maintenance of system operating parameters. Complete permissions assignment, add, modify, and delete data forms. At the same time, it has a complete login program (user name and password). Different personnel are given different permissions, which are set by the system administrator. The system also provides a one-key data backup and recovery function, which further ensures the security and continuity of business data.

The warehouse and traceability management of materials are perfectly combined with the automatic identification of RFID technology, so as to collect data and realize automatic storage and exit management. The uniqueness of RFID electronic tags and materials are bound to meet the possibility of material traceability and give full play to RFID can be applied to complex construction sites and other environments in the construction industry, which is much stronger than the service life of barcodes and the applicability of harsh environments.

[ad_2]