RFID helps a new generation of rapid detection technology for drug residues in honey

[ad_1]

Honey is a traditional nutritious food that is deeply loved by mankind. Since ancient times, it has been respected as a top-grade product for health preservation and healing, strengthening the body and strengthening the body. With the rapid development of my country’s national economy and the continuous improvement of people’s living standards, honey has already “flyed into the homes of ordinary people”, is favored by more and more consumers, and has received widespread attention from the general public and all walks of life.

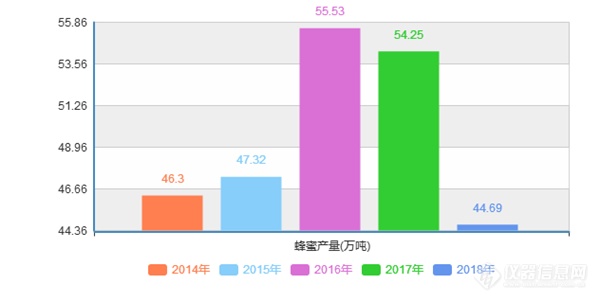

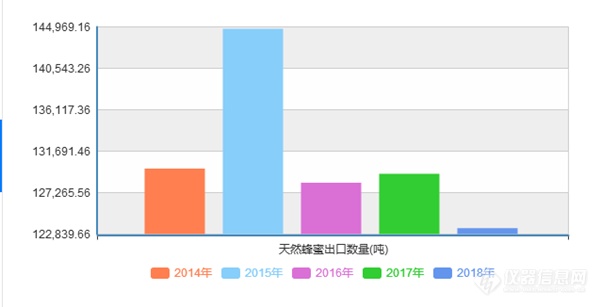

my country is the largest beekeeping country in the world. The number of bee colonies, honey production, beekeepers, and honey exports are among the top four indicators in the world. The total honey production accounts for more than a quarter of the world’s total honey production. According to the National Bureau of Statistics, the annual honey production in 2018 It was 446,900 tons, down 21% year-on-year, and showed a downward trend from 2016 to 2018. China is also an important honey exporter in the world, and its export volume ranks first in the world. In 2018, China exported 123,500 tons of natural honey, a year-on-year decrease of 4.5%; in 2018, China’s natural honey export value was US$250 million, a year-on-year decrease of 7.9%. Many developed countries are our trading partners.

Figure 1: China’s honey production statistics in the past five years Source: National Bureau of Statistics

Figure 2: Statistics of China’s honey exports in the past five years. Source: National Bureau of Statistics

Figure 3: Statistics table of export quantity and amount of honey

Honey has high edible and medicinal value, and it has become the main choice of modern consumers’ sweet condiments and healthy food. The quality and safety of honey has increasingly attracted consumers’ attention, and it is an important indicator that affects the growth of consumer demand. In the process of bee breeding, due to problems such as irregular medications used by individual beekeepers and insufficient drug withdrawal period, the problem of common drug residues such as chloramphenicol and tetracycline in honey exceeds the standard, which has seriously affected the development of my country’s honey industry.

After nearly 7 years of scientific research and technology research, Qinbang Biotechnology has successfully developed a new technology for rapid detection of drug residues in honey-high-throughput automatic chemiluminescence immunoassay technology, which is used for rapid detection of drug residues in honey with high efficiency. , High sensitivity, stable results, etc., to solve the problems of traditional detection methods such as long time, complex methods, and unstable results.

Technology Introduction

High-throughput automatic chemiluminescence immunoassay fast technology is a revolutionary new generation of high-tech detection methods in the field of food safety fast inspection technology. It integrates chemiluminescence technology, biological immunoassay technology, photon counting technology, automatic sensing and automated collaborative operation And other advanced technologies. The chemiluminescence reaction is a luminescence phenomenon in which the reaction substrate transitions from the ground state to the excited state. When the excited state returns to the ground state, the transition energy is released in the form of photons. The automatic chemiluminescence immunoassay analyzer reads the number of photons generated by the luminescence of the chemical and biological reaction. The number of photons has a linear relationship with the drug residue content in the test sample. The data collection and analysis software can accurately determine the drug residue in the test sample. This technology embodies the advantages of high efficiency brought about by automated standardized operations, the advantages of high sensitivity and wide linear range brought by photon counting technology, and the advantages of high precision brought by the specific binding of antigen and antibody.

Technical application: used to detect veterinary drug residues in animal-derived foods (meat, aquatic products, honey, milk, etc.) Test items such as carbendazim, erythromycin, tilmicosin, clenbuterol, ractopamine, etc.; used for the detection of pesticide residues in agricultural products such as vegetables and fruits, such as the detection of highly toxic pesticides such as carbendazim, procymidone, and DDT ; Used for the detection of mycotoxins in grains and oils, such as vomiting toxin in wheat, zearalenone in corn, aflatoxin B1 in peanut oil, etc.; and for the detection of nutrients in food, such as folic acid, vitamins, etc. .

Detection of Nitrofuran Drug Residues in Honey—New Experience Brought by the Automatic Chemiluminescence Immunoassay Method

1. Test data analysis

1.1 Standard curve

The calibration curve of the day was fitted by algorithm with the luminescence values of the four calibrators of furan. The detailed parameters of the calibrators are shown in the figure below, and the coefficient of variation of the calibrators is less than 5%.

Figure 4: Standard curve chart of nitrofurantoin metabolites

1.2 Accuracy (recovery rate)

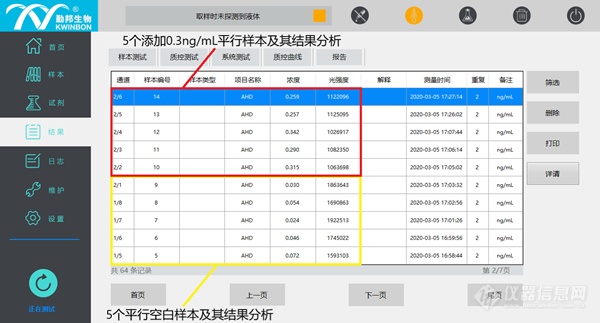

Nitrofurantoin metabolites were determined in 5 parallel blank samples and 5 parallel samples with 0.3ng/mL addition, and the recovery range was 86.3%-114%. Furantoin metabolites were measured in 5 parallel blank samples and 5 parallel samples with 0.3ng/mL addition. The samples were tested, and the recovery rate ranged from 91.7%-126.3%. The furazolidone metabolites were tested in 5 parallel blank samples and 5 parallel samples with 0.3ng/mL addition. The recovery rates ranged from 80.7% to 125%, and the nitrofurazone metabolites were 5 Parallel blank samples and 5 parallel samples with 0.3ng/mL added for determination, the recovery rate ranged from 88.3%-125.3%.

Figure 5: Verification of the accuracy of nitrofurantoin metabolites

1.3 Coefficient of variation

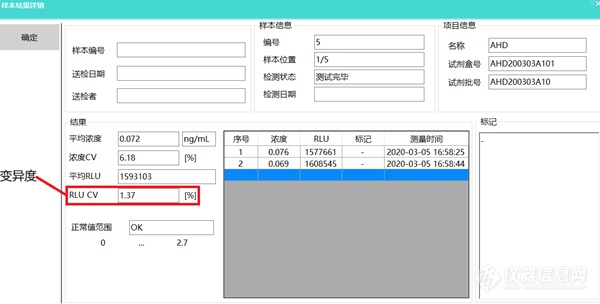

Figure 6: Variation of nitrofurantoin metabolites

The equipment reads the amount of photons produced by the reagent chemiluminescence reaction, the value is accurate and stable, and the coefficient of variation is less than 3%.

1.4 Detection time

A total of 40 samples were tested, 4 items of furan were tested at the same time, a total of 160 tests were completed, and the machine test (excluding pre-processing) took about 80 minutes. The first sample completed the test in 25 minutes, and then one report was reported in 20 seconds. result.

2. Conclusion (Method advantage)

2.1 The detection time of the fully automatic chemiluminescence detection technology is short, and the detection efficiency of large quantities is higher;

2.2 Automated cleaning and testing, standardized operation testing, not only shortened time, saved manpower, but also greatly reduced the experimental error caused by human operation, and improved the stability and accuracy of testing results;

2.3 Unattended detection improves the overall efficiency of technical operators, and at the same time makes the detection work easier;

2.4 Using RFID technology to read the information of detection reagents and samples, and automatically enter the software, which has better convenience;

2.5 Less chemical reagents are used, no radiation, which guarantees the health of testing personnel, and is also more environmentally friendly, reducing pollution treatment costs.

The use of Qinbang Bio-automatic chemiluminescence immunoassay detection technology can realize the accurate and rapid detection and analysis of the residues of furans and chloramphenicol in honey, which provides a more powerful way for the rapid screening of such drugs. solution. Fully automated chemiluminescence immunoassay technology is the current faster, more stable and accurate food safety rapid screening technology, which has realized the leap from manual operation to automatic operation in food safety detection, and is a necessary choice for the construction of food safety intelligent laboratories .

2. Application prospects

With the successful application of new technologies such as artificial intelligence, Internet of Things, and blockchain, the fourth industrial revolution has begun. Food factories are gradually thinking of upgrading and transforming automated and intelligent factories, and automated and intelligent food safety inspection technologies will be promoted and applied. , To help the construction of smart factories, with very broad application prospects. We will continue to innovate according to customers’ needs for new technologies, develop higher-end automated and intelligent food safety inspection equipment, serve the national manufacturing 2025 strategy, and lead the technological progress of the industry.

[ad_2]