RFID reader successfully applied to Hisense Hitachi air conditioner assembly line

[ad_1]

As the summer enters the Chinese air-conditioning market, many air-conditioners are in short supply. The full-load operation of factory production lines and the parallel assembly of different types of air-conditioners have become the development trend of the industry.

Hisense Hitachi Air Conditioning is an enterprise dedicated to the research and development, production and popularization of inverter air conditioners. It is a specialized enterprise integrating air conditioning technology research and development, manufacturing, marketing and technical services. The company has three domestic production bases in Qingdao, Shunde, and Huzhou, with an annual production capacity of more than 10 million sets. Its leading products cover household air conditioners, household central air conditioners, special air conditioners and other products, fully satisfying consumers with different climate regions, different characteristics and preferences The products are exported to more than 130 countries and regions around the world.

The cooperation between Hisense Hitachi Air Conditioning and Chenkong Intelligent RFID is to upgrade the air conditioner assembly line to achieve the purpose of improving assembly efficiency and reducing labor costs.

Generally, the daily production volume of the final assembly plant is controlled by scheduling, which serves as the basis for the logistics department to feed materials to the production line. The feeder often only estimates the feed volume of a fixed output based on experience, and cannot really grasp the actual material consumption of the assembly line. Even if a lineman is configured, the problem cannot be solved fundamentally. In order not to stop the final assembly line, and to ensure that the material inventory at the side of the production line is at a high safety level, the feeder is very intensive and prone to accidents.

In the production project of the final assembly line, a large number of workers need to be deployed to assist production on-line, and technicians are required to operate the mechanical equipment according to the on-site assembly schedule. The labor cost is high and the assembly schedule is unstable. Due to the large quantity of materials inside the factory, the occupied area is also large. On the one hand, the operation space of the final assembly line workers is reduced, and on the other hand, it is difficult to obtain materials, which affects the normal efficiency of the operation line. The material inventory and increased staffing further make the cost of the final assembly plant remain high.

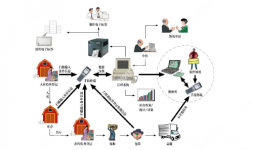

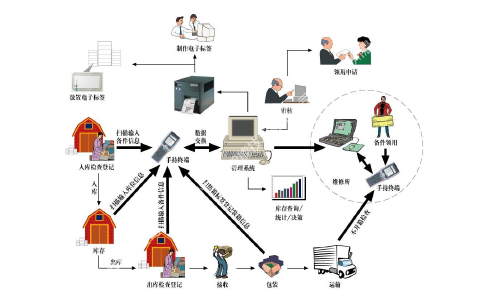

As a result, Chenkong Intelligent started with material supply and extended it to the product assembly line, and designed an RFID real-time information collection system, which has a leading position in the world to improve the real-time transmission of material information and the timeliness of material supply , Master the assembly process nodes, and then improve the overall assembly efficiency of the entire production line. At the same time, reduce the configuration and cost of line inspectors.

At present, Hisense Hitachi air-conditioning assembly plant has applied this system, while FAW, Shanghai Volkswagen, Haier and other large companies have cooperated with Chenkong Intelligent. This solution will also be promoted in other enterprise assembly lines. Guangzhou Chenkong Intelligent RFID team is a national leading RFID technology research and development and RFID solution integrator to help customers realize the visualization of collected information and real-time information management, and optimize the accuracy and reliability of management.

Improve the level of customer management, so as to effectively control production costs. Chenkong Intelligent provides one-stop services for data collection and analysis, planning and design, project implementation and commissioning to after-sales service. At present, the morning control intelligent RFID team has established cooperative relations with hundreds of large enterprises in Asia, and completed a large number of wireless network-based RFID information control systems.

[ad_2]