RFID realizes the informatization and timeliness of warehouse management

[ad_1]

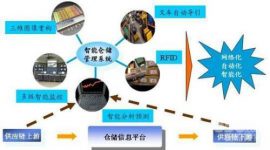

The importance of the warehouse can be imagined. The most important part of enterprise management is how to make the warehouse efficiently used. The rent of the site is getting more and more expensive, and the turnover speed of the goods in the warehouse needs to be continuously accelerated to increase the frequency of use of the warehouse. Therefore, the warehouse of the same area has to become higher (shelf), faster (turnover) and stronger (management). Therefore, modern warehouse inventory management is constantly upgrading and optimizing. In the management of modern warehouses, the efficiency of warehouse entry and exit will directly have a huge impact on the economic benefits of the warehouse. Through RFID technology, scientific and effective warehouse location management, warehouse entry and exit, inventory inventory, and warehouse management information and timeliness will be realized. change.

RFID technology achieves superior functions such as non-contact, repeated use, fast scanning, and large data capacity. More and more warehouse management uses RFID technology to maximize warehouse management efficiency on the basis of informatization and digitization, and enhance the core of the enterprise Competitiveness.

The warehouse management system design adopts the following three-tier structure:

Information collection layer: The new goods are equipped with RFID electronic labels through the issuance of cards and RFID electronic labels. The unique ID number of the label or the code written by the user can identify the goods. The reader can automatically collect tag information, so as to realize the information collection function of the goods.

Data transmission layer: The goods label information collected by the RFID reader can be transmitted to the back-end system for analysis through the relevant communication interface. The communication interface for transmission can be selected according to user needs. You can choose RS-485, RS-232, and Ethernet. Internet, WIFI, 4G or GPRS, etc.

Cargo management

After the PC terminal or the back-end data center receives the data from the reader, it analyzes the data to determine the flow of goods out of the warehouse, warehousing, shifting, and inventory, and at the same time generates a corresponding report indicating the detailed list, and makes the corresponding in the system的处理。 Treatment.

The hardware of the RFID warehouse management system is mainly composed of RFID electronic tags, fixed readers, handheld readers, servers, personal computers, etc., and realizes mutual connection and data exchange through the network.

The RFID warehouse management system software is composed of a supply chain management system, an RFID tag issuing system and an RFID tag identification collection system. These systems are connected to each other to jointly complete the various processes of item management. The back-end database management system is the core of the whole system, and RFID identification collection is the basis and means to realize the management function.

The RFID warehousing logistics management system consists of card issuance and labeling, outbound management, inbound management, allocation and shifting, inventory counting and additional functions. The outbound management system includes outbound goods claim, outbound goods identification, and outbound record download. The warehousing management system includes location allocation setting, unloading product identification, and warehousing record management.

RFID technology warehouse management workflow:

Write, issue, and label RFID electronic tags:

Label the newly purchased goods and equip them with RFID electronic tags. The unique ID number of the RFID electronic tag or the data written by the user can be used as the identification code of the goods, and the data is used to record the name of the goods, the time of purchase, the warehouse to which they belong, and the attributes of the goods. When the readers installed in each channel recognize the RFID electronic tags, they can automatically obtain all the information of the goods.

Storage:

First, arrange the storage location on the system for the goods that need to be stored, such as which category the goods belong to, which warehouse and which shelf they need to be placed in; secondly, put all the items that have been affixed with RFID electronic tags to the storage area to be stored, from the inbound channel Transported into the warehouse; when passing through the channel, the RFID reader will automatically identify the tag information, if the tag information and quantity recognized by the reader are correct, it will be put into the warehouse. If the tag information recognized by the reader is wrong or the quantity is small, the system will Prompt; when warehousing, the operator can accurately store the goods in the corresponding warehouse area according to the label information and system prompts. At the same time, the system will automatically follow the item information (date, material, category, quantity, etc.), and form a warehousing list Breakdown.

Out of the library:

To apply for outbound goods, fill out an application form for outbound goods on a personal computer.

After receiving the outbound order, the warehouse management personnel find out the corresponding items through the handset or query the server, and place the goods in the outbound area.

The goods to be out of the warehouse with RFID electronic tags will be identified by the RFID reader device through the entry and exit channel before loading.

The outbound channel reader device checks the identified RFID electronic tag information with the outbound application form to confirm whether the loaded goods are consistent. If they are inconsistent, repeat the identification or supplement the shortage.

The system automatically updates the item information (date, material, category, quantity, etc.), and forms the outbound list details.

Allocate and move the library:

The goods to be transferred to the warehouse will be identified by the RFID reader installed next to the passage when they pass through the passageway. The RFID reader/writer records the current tag information and sends it to the back-end center. The back-end center judges whether it is warehousing, outgoing, or transfer according to the sequence of the entry and exit channels to identify the RFID electronic tags. The goods can also be moved through the RFID handheld machine. When the warehouse manager finds that a certain goods has been placed in the wrong position, he can manually place the goods, and at the same time, by changing the RFID electronic label information and sending it to the server, the quick and convenient movement can be realized. Bit function.

inventory check:

Account check: Obtain the information in the RFID tag of the cargo location through the RFID handset, and check the information with the information in the warehouse management system. The manager only needs to take the RFID handset and walk through the cargo locations to complete the inventory.

Account verification: By verifying the RFID electronic label information of the specific goods and the information stored in the warehouse management system, each physical object is checked and verified to ensure the authenticity of the RFID electronic label and the object.

RFID warehouse management application uses advanced RFID technology, combined with wireless local area network, database and other technologies to perfectly integrate the entire warehouse management with RFID radio frequency identification technology, which can efficiently complete various business operations, improve warehouse management, and increase efficiency and value.

[ad_2]