RFID technology for real-time management and control of material life cycle

[ad_1]

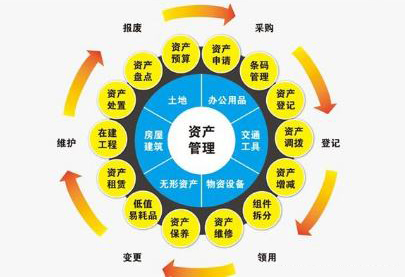

The RFID technology material management system includes the real-time management and control of the entire life cycle of material addition, storage, delivery, allocation, distribution, maintenance, use, inventory, and scrap. The material management system replaces the front-end manual data collection of traditional asset management methods through remote, dynamic, and real-time equipment asset data collection, and better combines with the back-end material management system to form a fully intelligent asset management system that can improve material management Enhance the timeliness and accuracy of material management and control. RFID technology carries out real-time management and control of the material life cycle.

Advantages of RFID technology material management system:

(1) The entire system has the characteristics of long-distance rapid identification, high reliability, high confidentiality, easy operation, and easy expansion.

(2) Establish safe and reliable asset files, strengthen asset supervision through high-tech, rationally allocate resources, reduce resource waste, and prevent asset loss.

(3) Fully consider the actual situation of the company, study problems from the perspective of professional technology, and effectively solve the chaotic, disorderly and poor real-time problems in asset management. Provide an advanced, reliable, and applicable digital platform for automatic identification and intelligent management of incoming and outgoing assets, so that the company’s ability to manage internal assets in real time and dynamically is qualitatively improved.

(4) Make full use of the RFID automatic collection and wireless remote transmission function of communication to realize the real-time consistency of asset change information and system information, and realize the effective real-time monitoring and recording of the work process by the back-end system, so that managers can be in the office. Learn about the allocation and use of assets in a timely manner.

(5) All asset data are entered at one time, and the system automatically judges the asset status based on the data collected by RFID in different areas.

In order to optimize inventory, improve the efficiency of item management, grasp inventory status, and realize intelligent, scientific and automated inventory management. The inventory management office adopts the management methods of numbering, account creation, and card creation for the inventory items in the unit, and regularly checks and counts the items, accounts, and cards of the inventory items, and performs statistical printing reports at the end of the year. RFID technology performs automatic asset information inventory collection, reducing a large amount of manual inventory time and improving work efficiency.

By installing RFID electronic tags on each item, use a desktop RFID card issuer to correspond each RFID electronic tag with the asset item name, picture, ownership and other information to be managed, and attach it to the asset item for unification Manage and write data so that the RFID electronic tags correspond to the actual items one by one. In actual applications, the RFID reader reads the RFID electronic tags and the corresponding items will be displayed.

Install RFID card readers and antennas on the inside and outside of the warehouse door, etc., to quickly identify the RFID electronic label information of an item taken from the warehouse, and realize accurate, fast, and automatic barrier-free inspection of personnel entering and exiting important passages .

[ad_2]