RFID technology helps asset management of smart grid

[ad_1]

In recent years, my country has included the Internet of Things and smart grid networks as a national key project. The introduction of Internet of Things technology into smart grids can not only effectively integrate resources and infrastructure in all aspects of power production, transmission, distribution and consumption, and improve The informatization, intelligence and integration of the power system have greatly improved the utilization rate of the power infrastructure.

The Internet of Things includes three levels: perception layer, network layer, and application layer. The smart grid designed based on the composition of the Internet of Things consists of a perception layer, an analysis layer, a data layer and an application layer.

1. Perception layer

Data collection and perception are mainly used to collect data on power supplies and equipment. In the power Internet of Things, the State Grid Corporation of China identifies information resource data such as power materials, equipment, and assets into an RFID electronic tag. Such as material classification code, equipment classification code, functional location code, etc.

2. Analysis layer

Through the RFID handheld terminal, the information of the perception layer can be analyzed and transmitted without barriers, high reliability, and high security.

3. Application layer

It mainly includes the application support platform sub-layer and the application service sub-layer. Among them, the supporting platform is mainly an ERP platform. Application services mainly include power material procurement management, equipment inspection and maintenance management, fixed asset management, and asset life cycle management based on this.

4. Data layer

To be precise, the data layer does not belong to a specific layer of the Internet of Things technology, but uses PDA security technology to parse the data to the data center.

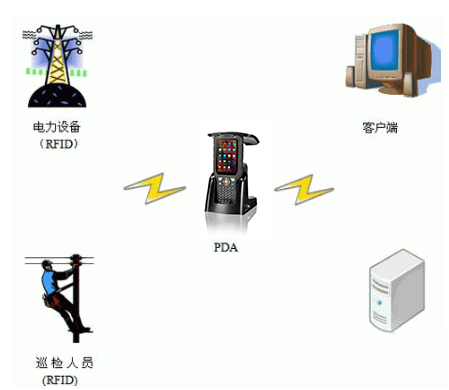

The system structure diagram of the smart grid designed based on the above architecture, in which power equipment, inspectors and electronic tags covered on it belong to the perception layer, PDA handheld computing devices belong to the analysis layer, and the client PC and server correspond to the application layer of the system And the data layer. The Internet of Things for smart grid applications should mainly include a perception layer, a network layer, and an application service layer. The perception layer mainly uses wireless sensor networks, RFID and other technical means to realize the collection of relevant information of each application link of the smart grid; the network layer is mainly based on the power optical fiber network, supplemented by the power line carrier communication network and wireless broadband network, to achieve various types of perception layer Information transmission in a wide area or a partial range of power system information; the application service layer mainly adopts intelligent computing, pattern recognition and other technologies to realize the comprehensive analysis and processing of power grid information, realize intelligent decision-making, control and service, thereby improving the various applications of the power grid The level of intelligence of the link.

What are the applications of RFID technology in smart grids?

Power Asset Management

Traditional electricity meter management generally uses barcodes. However, it was later confirmed that the barcode information cannot be changed and the capacity is small. The barcode labels are easy to fall off and damage, which easily affects the normal reading of the equipment. Therefore, the power company uses RFID instead of barcodes to realize the effectiveness of the electricity meters. manage. Attach RFID electronic tags to the electric meters, and then collect the data information of the electric meters through the corresponding RFID equipment, and manage the fast in and out of the electric meters through the RFID channel machine, which realizes the batch identification of the RFID tags of multiple boxes of electric energy metering equipment.

Electrical equipment management

Whether it is installing access doors at the entrance of a small warehouse or using other methods such as platform installation to manage warehouse tools, when workers use readers to read tool tags, there will inevitably be cross-reading and omissions that make it unclear which ones are taken away. The question of what kind of tool. Using RFID technology, put the tools with RFID electronic tags into a specially customized smart tool cabinet equipped with RFID readers. Whenever the tool is taken out of the cabinet, the system will record this operation in real time. It will immediately determine the details such as: who, the main responsible position, when what tools were taken out, and when to return them. The system can also set operating permissions, and can automatically issue a warning when a tool is not returned within a certain period of time.

Operating procedures:

The fully enclosed cabinet provides a keyless entry method, and it is easy to store tools → After the employee swipes the employee card and touch screen login is completed, the cabinet system is turned on, and the employee is authorized to access the tools → click the required tool on the touch screen, and the corresponding The electromagnetic lock of the tool storage drawer will be automatically opened, the software will automatically record each access operation in real time, and automatically update the database → Once the access operation is completed, when the drawer is closed, the touch screen will immediately display the update status of the item.

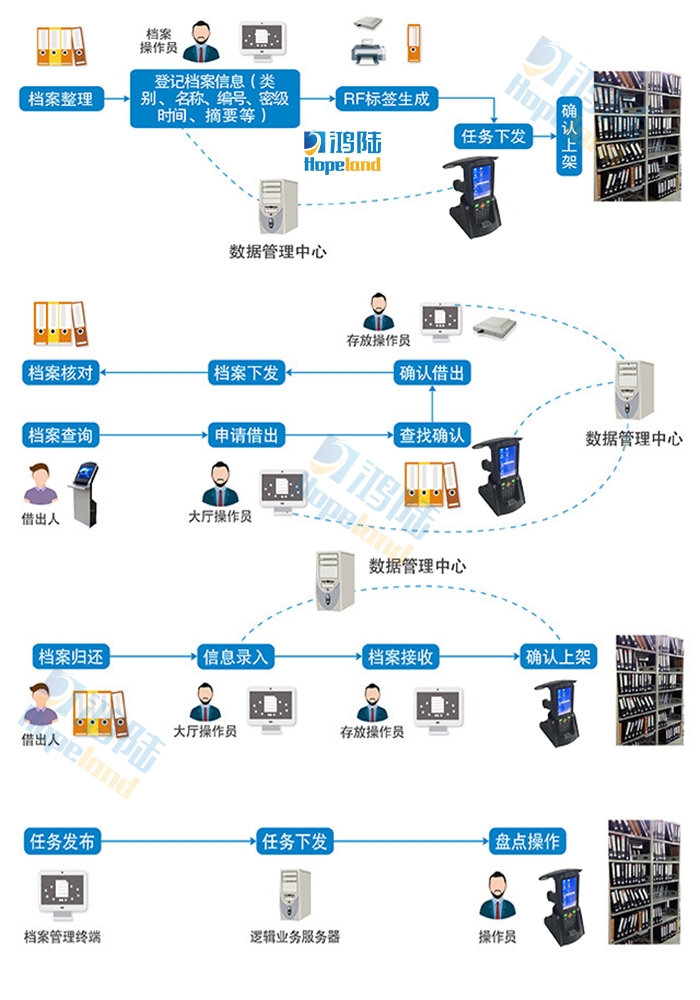

Power file management

Generally, file management based on RFID technology consists of a system and terminal management equipment. Its terminal management includes RFID electronic tags, Honlu UHF channel access control, UHF handheld terminals, Honlu RFID read-write equipment and card issuers, etc., which are systems to obtain information An important port with output information. The whole system realizes the informatization management of the archives management process through the close cooperation of all links. Among them, the Honglu UHF handheld terminal plays a pivotal role in the deployment of the entire RFID system. It can quickly realize file storage, borrowing, returning, and querying. The specific workflow is as follows:

Power inspection management

Power equipment inspection is a basic work to effectively ensure the safety of power equipment, improve the reliability of power equipment, and ensure the minimum failure rate of power equipment. Through the RFID handheld terminal, paperless data collection can be realized, and at the same time, the equipment and power equipment management department can effectively supervise the work of the inspectors, and realize the electronic, informatized and intelligent inspection work, thereby maximizing the work Efficiency ensures the safe operation of power equipment and power equipment with a low failure rate.

Compared with traditional power grids, smart grids can achieve intelligence based on the complete grasp of the information of the power grids, based on the premise that RFID read-write devices collect data, and ensure the safety, stability and reliability of data in the process of data transmission and conversion. The smart grid realizes the management of the entire life cycle of equipment, reduces the workload of equipment storage, inspection and other links, and improves the automation level of equipment management.

[ad_2]