Site Safety Wireless Management System

[ad_1]

Safety Application

The construction industry is the main foundation of national economic construction, closely related to the national economy and people’s livelihood, and is the basic industry of national construction. It has always played an important role in national construction and development, and at the same time affects the development of related industries. Therefore, it has always been known as the “locomotive industry”. , and shoulders the mission of national construction, economic prosperity and benefiting people, so no matter in developed or developing countries, construction engineering industry has always occupied a very important industrial position.

However, the construction industry is a special industry, and the dangerous situation is much more than several times to dozens of times more than other industries and occupations. A little carelessness may cause casualties. Most of the workers engaged in construction projects have no specific employers and have high labor mobility. Various phenomena show that construction projects can easily become a blind spot for occupational disaster prevention.

The Challenge

In the past year, 63% of construction workers had suffered minor occupational injuries, and 23% had suffered serious occupational injuries. This high data shows that construction sites are still a high-risk area. The working environment and the safety issues on the construction site still need to be improved. Among the major occupational disasters every year, the probability of major occupational accidents in the construction industry ranks the highest in the entire industry (accounting for more than 50% of the entire industry), and most occupational disasters are caused by human factors. The number of industrial safety accidents is increasing year by year. It is obvious that with the rapid development of the construction engineering industry, there are also many blind spots in task safety. As long as there is a slight negligence, it will cause harm to people’s lives, and it will also involve many families. Financial burden and sadness sad. There are many main causes of major occupational disasters in the construction industry, which can be roughly divided into the following categories:

1. Insufficient safety facilities provided by employers

2. Refurbishment of building technology, but still managing the site in the old way

3. Construction workers have weak safety awareness and are prone to accidents

4. External elements are difficult to control, bringing risks and threats

5. Gas explosion, fire and collapse at the construction site

6. Intentional suicide of workers

The construction industry is currently facing the following four daunting challenges:

Insufficient safety facilities provided by employers

Refurbished building technology, but still managing the site the old way

Construction workers have weak safety awareness and are prone to accidents

Outsiders are difficult to control, bringing risks and threats

The Solution

The operation mode of the construction site safety management system is based on the combination of Active Zigbee Tag, RFID Reader with ZigBee network function and various sensors with different detection functions (such as Motion Sensor, Pressure Sensor, G-Force Sensor, etc.) Wi-Fi or other network transmission mechanisms are used in specific areas to achieve comprehensive real-time detection and monitoring targets in the control area, including personnel movement trajectories, dangerous areas, toxic gases, temperature changes, object circulation, or vehicle movement. .

In order to monitor the walking path of construction workers, once the tag enters the detection range of a locator, it will actively send out a signal. After the locator detects the signal of the tag, it will transmit the data of its tag to the reader. The number of layouts will affect the read rate. The advantage of active RFID lies in the power source attached to the tag itself, which makes the transmission distance longer, and the read error rate can be greatly reduced.

Key Features

Active ZigBee Tag

IEEE 802.15.4 ZigBee™ Compliant

Supports flexible topology design based on ZigBee™ network, such as star, hybrid tree, mesh, etc.

Perfect application software can easily set relevant parameters of ZigBee™ network, which simplifies network construction

Support low power consumption, low frequency wake-up and Sensor integration function

RFID Reader

IEEE 802.15.4 ZigBee™ Compliant

Supports flexible topology design based on ZigBee™ network, such as star, hybrid tree, mesh, etc.

Perfect application software can easily set relevant parameters of ZigBee™ network, which simplifies network construction

Signal emission intensity can be adjusted and supports low frequency wake-up function

ZigBee-GPRS Gateway

l Compliant with IEEE 802.15.4 ZigBee™ and GPRS standards

l Supports flexible topology design based on ZigBee™ network, such as star, hybrid tree, mesh, etc.

l Web Based setting interface

l Support Ethernet network connection function

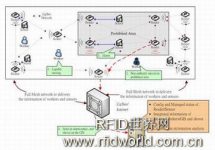

Construction Safety Chart

System Description

The industrial safety management system provided by Helixon Technology is composed of short-range and GPRS long-range wireless communication networks based on ZigBee, providing tracking management of personnel and equipment in construction sites, coupled with back-end GIS, positioning engine and management databases , which can indeed achieve integrated wireless solutions such as reducing industrial safety accidents, environmental monitoring, asset management and site management. The solution equipment includes Active Zigbee Tag, RFID Reader with ZigBee network function, and ZigBee-GPRS Gateway. Standard RS-232/RS-485 and Ethernet interfaces can be directly connected with professional industrial control acquisition equipment and professional detectors.

Equipment maintenance and firmware upgrade, support the over-the-air update function FOTA (Firmware Over The Air), making system management more flexible and efficient.

Please log in for more details www.helicomm.com.cn

[ad_2]