Taiwan Phalaenopsis Production Management RFID Application

[ad_1]

According to the annual report of agricultural statistics of Taiwan Province, the planting area of flowers is about 14,000 hectares, and the annual output value is about 12.5 billion yuan, accounting for only 1.78% of the total agricultural production area and 7.25% of the total output value, but the output value of flowers per hectare is as high as About 940,000 yuan, the highest for crops, far higher than 110,000 for rice and 320,000 for fruit trees. Flower production can be roughly divided into five categories: cut flowers, orchids, bulbs, seeds and seedlings. Among them, orchids have an area of about 600 hectares and an annual output value of about 2.8 billion, accounting for only 4.29% of the total flower production area and 22% of the total output value. However, the output value of orchids per hectare can be as high as 4.8 million, which is much higher than the average of 940,000, which shows that orchids create crops with higher output value in the production of economic flowers. Therefore, orchids are currently the most representative agricultural biotechnology industry in Taiwan. Phalaenopsis, Oncidium and Cymbidium are the largest ones. There are also a few professionally cultivated orchids such as Dendrobium, Cindy orchid. Phalaenopsis has become the most important flower crop in Taiwan with about 80% of its production area and export value. The international market for Phalaenopsis is also growing rapidly.

Improving the Breeding and Cultivation Techniques of Phalaenopsis

Taiwan Province spares no effort in the research and development of phalaenopsis breeding and cultivation technology, and develops modern intelligent greenhouses suitable for Taiwan’s local climate and environment, establishes an annual flowering and cultivation system, and develops export markets, so that Taiwan phalaenopsis has a place in the international market, planting area and output It has been continuously improved, and currently it is mainly exported to Japan and the United States. In recent years, Taiwan has faced the threat of low prices from mainland China and Southeast Asian countries, and the high-priced market has faced competition from the Netherlands. In order to improve international competitiveness and develop export markets, how to improve quality, improve efficiency and reduce production costs has become the sustainable development of the Phalaenopsis industry. research topic.

Taiwan has actively invested in the improvement of phalaenopsis breeding and cultivation technology, and developed a modern intelligent greenhouse suitable for Taiwan’s local climate and environment, established an annual flowering and cultivation system, and developed the orchid export market, so that Taiwan’s phalaenopsis has a place in the international market. The planting area and output have been continuously improved. The “Council of Agriculture” even listed Phalaenopsis as the first of the four major agricultural flagship products in Taiwan Province. It is currently the most promising agricultural product in Taiwan with an international image. Currently, it is mainly exported to Japan and the United States. In recent years, Taiwan has faced the threat of low prices for phalaenopsis from the mainland, and the high-priced market has been controlled by the Netherlands. In order to improve international competitiveness and open up export markets, improving quality and reducing costs have become two major issues faced by the phalaenopsis industry.

Application of RFID in Phalaenopsis

Phalaenopsis industry is a relay production. The production stage of bottle seedlings lasts for one and a half years, and it takes one year to grow from 1.5-inch seedlings to 3.5-inch large seedlings. These two stages of seedling reproduction, nutrient solution use, and pests and diseases will affect the cultivation. The low breeding rate is the main reason for the high cost of Phalaenopsis operators. If RFID technology can be combined with PDA work log, it can automatically remind and follow up production records and work schedules, and automatically record production records, seedling reproduction, pests and diseases. Management and mobile management, etc., will help improve the breeding rate and increase the profit of the industry.

Generally, the Phalaenopsis greenhouse is about 10,000 square meters, and there are tens of thousands of plants from small seedlings to large seedlings. The same situation is also observed in tissue culture bottle seedlings. Therefore, quantity and location management is not only labor-intensive and time-consuming, but also not accurate. If RFID can be applied The ability to quickly read in inventory management will improve inventory management efficiency and save labor inventory costs. At present, most phalaenopsis companies cannot immediately report the precise production progress, inventory and delivery time of customers. The main problem is that the inventory is time-consuming and the breeding rate is low. It will improve the breeding rate and inventory efficiency, thereby improving the accuracy of order delivery and shipment quantity, improving customer satisfaction, and increasing industry profits.

In addition to the application of RFID in internal production management, if it can be combined with EPC in the supply chain, it will have the value of innovative services for export logistics operations. Electronic Product Code (EPC) is a common coding principle that uses RFID technology to identify the only way of physical objects. This concept is an innovative application of RFID technology developed by MIT (Massachusetts Institute of Technology) in conjunction with major global retailers. The combination of EPC and RFID technology can automate the tracking of items in the supply chain of different systems, and improve the efficiency of supply chain management. However, to expand the use of RFID beyond closed applications within an enterprise and benefit the entire supply chain, a standardized approach is needed to search and share information about EPCs; this is the role of the EPCglobal Network. EPCglobal Network creates a low-cost standardized service based on the existing Internet architecture to help trading partners to search for information related to each EPC. If Taiwan phalaenopsis operators can cooperate with transportation operators and foreign phalaenopsis, use the EPCglobal Network international standard network structure to exchange information between upstream and downstream, improve the information transparency of the entire industrial supply chain, and further strengthen the commercial relationship between Taiwan Province and foreign operators , so that both parties become inseparable partners.

Full control of Phalaenopsis production management

The Flower Research Center of the Agricultural Experiment Institute of the Agricultural Committee of the “Executive Yuan”, with the support of the Information Center of the Agricultural Committee of the “Executive Yuan”, has carried out the application scenario planning and application of Radio Frequency Identification (RFID) technology to the production management of Phalaenopsis. Proof of Concept. The verification results found that the introduction of RFID technology into the Phalaenopsis value chain management system to control the entire process of tissue culture and greenhouse cultivation and data traceability can improve the transparency of supply chain information, increase the speed and accuracy of data collection, and use on-site real-time collection. The data can be used as the basis for immediately improving the operation process, improving the management efficiency and added value, which can effectively improve the international competitiveness of Taiwan Phalaenopsis.

The schedule of this plan is 4 years since 1996. The important work items and achievements are as follows:

1. Build a production management system and an RFID communication platform:

(1) Inventory of operating procedures and production control processes

The production mode of general operators can be divided into “order-to-order production” and “mass production”. The mode of make-to-order production is to start planning production when there is an order. The mode of mass production is that the industry predicts the production quantity according to the market conditions, and then starts to plan the production.

(2) Development of production history record software and database

According to the operating procedures and production control processes listed in the inventory, design production history records, import the RFID automatic reading management system for application in management, and use the RFID reader antenna configuration to dynamically read the RFID tag identification code regularly or programmatically, so as to accurately grasp the The number of seedlings, the record of the process of succession and pot changing, the relationship chain tracking management by reading the identification code on the RFID tag, and the establishment of a traceability database.

(3) Development of systems and intermediary software

In line with the production history record process and database structure, the development of the system and middleware has been completed.

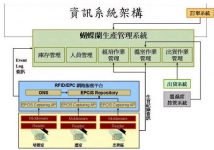

Figure 1. Architecture diagram of RFID communication platform under planning

2. Application of RFID in production process management of tissue culture room and greenhouse

The bottle seedling label is designed and developed for tissue culture, and it is used in the management of orchid seedlings with the automatic reading management system of the cultivation rack. The RFID reader antenna on the rack is configured to dynamically read the labels on the bottle seedlings regularly or programmatically, and accurately grasp the number of various bottle seedlings on the rack, which is convenient for the industry to manage the inventory. The records of the bottle seedling process can be tracked and managed by reading the identification code on the bottle seedling label.

Figure 2. RFID management of tissue culture flasks on a tissue culture rack

The cultivation and shipment management of bottled seedlings in the sub-bottle stage of the greenhouse operation and the bottled seedlings after they have emerged from the bottle will enter the greenhouse operation. Develop labels for greenhouse operations to facilitate inventory and daily management operations. Similarly, RFID technology can be used to achieve the goal of tracking production history.

3. RFID shipping operations

Taiwan Province is the world’s largest producer of orchids, known as the “Phalaenopsis Kingdom”. In the past decade, the Netherlands has challenged Taiwan through automated mass production. Taipei Flower Production and Marketing Company estimates that the Netherlands will surpass Taiwan’s production for the first time in 2008. In addition, the mainland’s low-cost sales strategy is catching up, and the business competition in the global Phalaenopsis industry will become more intense. Taiwanese companies should actively take advantage of the advantages of seedling breeding, and strengthen cooperation opportunities with Phalaenopsis companies from various countries to take over the cultivation in the later stage, so as to form a complete industrial supply chain.

Figure 3. Potted seedlings erect RFID tags to assist production management

The application planning of EPC information exchange related to this project is mainly based on shipment event information: in the operation process, the two RFID readings of “sealing” and “shipping” are used as different types of EPC event information, including ” The ObjectEvent application context of the “sealing” operation and the TransactionEvent application context of the “shipping” operation, and the Phalaenopsis production management system uploads the data to the EPCglobal Network network architecture. This application only proves that the EPC event information on the seedling production side (Taiwan phalaenopsis industry) can be uploaded using the EPCglobal Network network architecture. The external sales channel end makes the information of the entire industry supply chain more transparent, and helps Taiwan Phalaenopsis manufacturers to grasp the market trends outside the province.

Expected benefit

Drive RFID R&D energy and industrial demand

In the experimental evaluation stage, through appropriate scenario planning and field testing, it is estimated that about 5,000 passive labels will be used (300 ping greenhouse, 100 plants/ping, 6 plants/taq). The test is completed. If it can be successfully used by industry, the annual production capacity of Phalaenopsis in Taiwan is about 70 million, which will greatly increase the demand for RFID tags and readers.

Keep abreast of foreign orchid markets

At present, Taiwan Phalaenopsis manufacturers are still unable to grasp the market conditions outside the province, and can only passively rely on the order requirements of foreign manufacturers for production planning. In order to make more flexible management, actively adjust the production plan according to the situation.

According to the planned schedule, this year (97) has cooperated with manufacturers in Taiwan’s Orchid Biotechnology Park, and is currently conducting system tests in the actual commercial production environment.

[ad_2]