The position of digital transformation of the cable management industry under RFID tags

[ad_1]

Due to the relatively hidden operating environment of the cable line, due to the imperfect operating data and the limitation of the channel test equipment, it is very difficult to identify and troubleshoot the parallel cable ducts in the same path. When the cable line fails, although the fault point can be found through the equipment location However, due to the unclear on-site identification and the impact of the work well environment, the work well where the faulty cable is located cannot be confirmed, resulting in accidental excavation of roads, low efficiency of cable fault handling, and negative social impacts.

Such an accident occurred in Texas in 1983. Because Texas has a tornado season every year, a tornado disrupted thousands of cables in the town, and the repair of these cables happened to require the interface with the cables. There is a one-to-one correspondence. This not only gave the Texas cable maintenance department a lot of trouble, of course, they repaired it in the end, but we can actually find that the cable management problem is very tricky and obvious. Even if this problem is now, it is still not easy to solve.

According to statistics, the proportion of cable failures due to urban construction, trench fires, and theft is as high as 76%, and this proportion is even higher in some cities with large renovations and older cities. In the past, if the amount of cables in the back-end database room was in thousands, it would now reach the level of more than 100,000. This is a very severe test for cable management. If there are faults and cable function problems, how to make the data cable at the level of 100,000 Find the corresponding cable here. This is a big project. At present, in daily cable management, it is difficult to carry out normal inspections; inspection responsibilities cannot be clearly implemented; accidents are often sudden, large-scale power outages and emergency repairs of key users, and senior management personnel are under great work pressure .

On this issue, RFID will show its powerful functions and advantages.

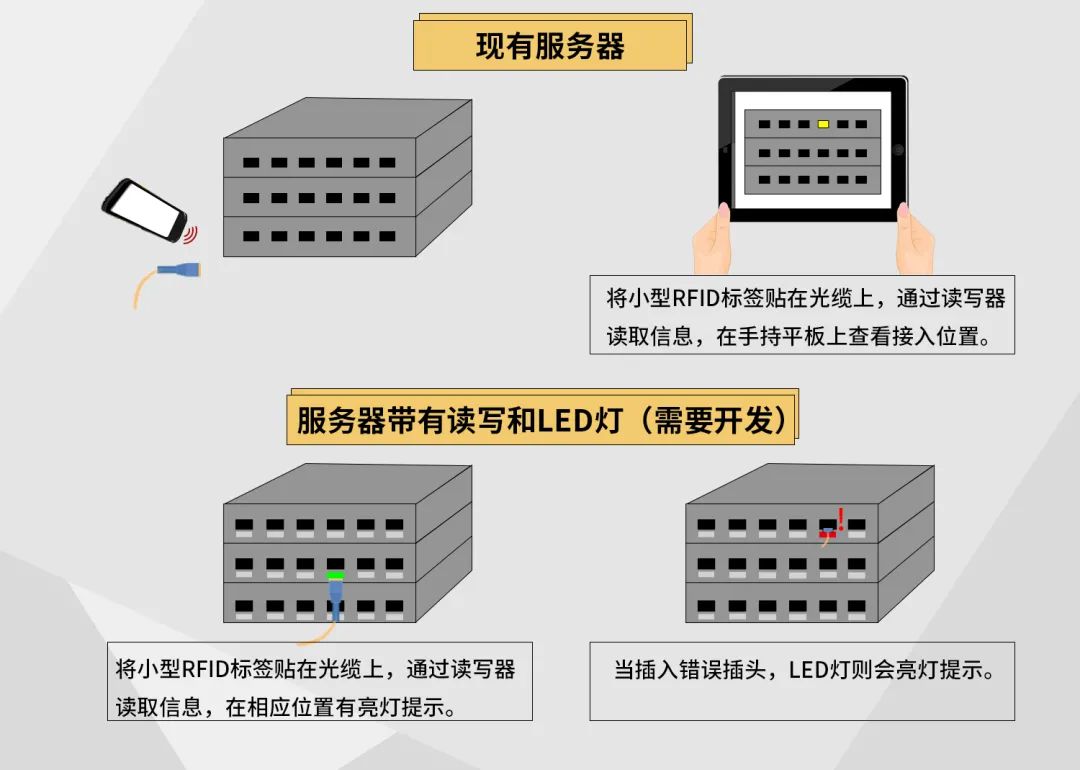

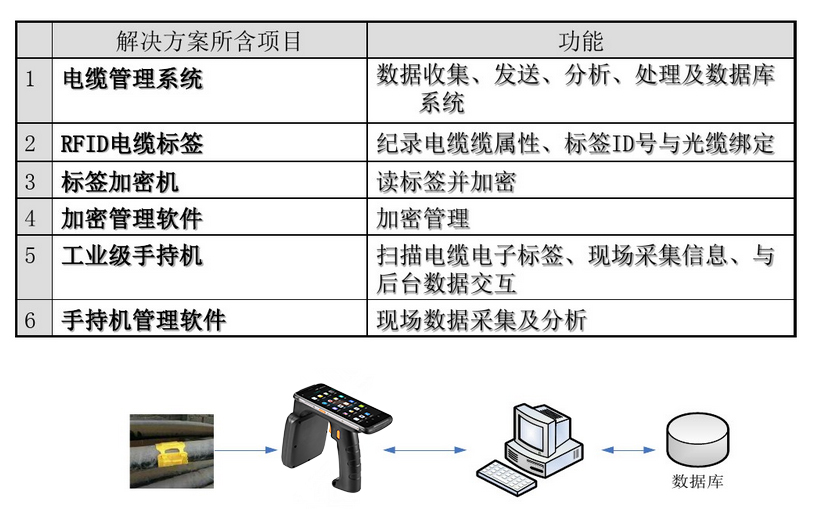

Through UHF RFID technology, more accurate reading ability and longer reading distance can identify smaller RFID tags. Engineers only need to install a small RFID tag on the cable, and then use the UHF handheld reader display or LED beacon to quickly find the corresponding problem cable.

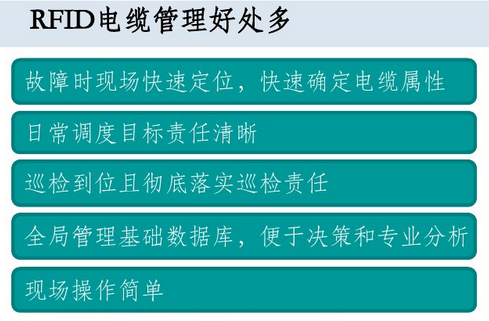

RFID cable management, the passive UHF electronic tag that records the cable attributes is firmly bound to the cable, and the industrial-grade UHF handheld machine is used to read the electronic tag information bound on the cable, which can quickly Determine the attributes and information of cables, and provide reliable scientific management methods for cable inspections, rapid repair of cable faults, and cable asset system inventory.

In the management, the patrol inspector’s handheld RFID reader can realize the efficient management of the whole process from inspection defect discovery to defect processing, reducing the workload of operation and maintenance personnel; improving the efficiency of daily operation and maintenance management; ensuring the operation and maintenance of the operation department Standardization and standardization of management workflow; to realize the rapid positioning of cable path channel information, effectively improve the background digitization and information management level of cable path channels, and provide guarantee for the safe operation of cable lines.

[ad_2]