What kind of sparks will RFID technology combine with molds?

[ad_1]

The rapid development of industry, and mold, as the mother of industry, has become an indispensable basic industry for industrial development. The mold market has been continuously making breakthroughs in technology. The mold industry is no longer just a simple machine like the traditional one. Now the mold needs to integrate a lot of technology, and it is moving towards intelligence and networking. The RFID mold electrode management system better realizes the intelligent management of the mold, reduces the professional skill requirements of the mold operators, and greatly improves it, reducing the factors of mistakes. This effectively improves the increase in the rate of movement of machine tools.

The development of modern industry has been reflected in many fields. Industry has always been an important hub of the national economy. The mold industry has been increasing in my country in recent years, but there are still many management problems in the mold industry market. Moulds are indispensable processing tools and process equipment in mass production in modern manufacturing. Like all kinds of machined machine tools, they have an important industrial status. With the rapid increase in the number of molds with diversified products of enterprises, and processing a mold often requires dozens or even hundreds of electrodes, electrodes have become a huge number of key resources in the mold manufacturing industry. By installing RFID electronic tags on the electrode holder, associating the electrode holder and electrode information, and a handheld RFID reader, this solution is expected to reduce copper working materials by 15%~35%, reduce CNC operators by 15%~40%, and increase The utilization rate of CNC and EDM machine tools is about 5%. For small and medium-sized mold companies, informatization is a good choice, with little investment and quick results. It can be done in one section by section. After the automation technology is mature, it is easy to realize full automation by simply connecting the various sections in series, adding mechanical arms and guide rails.

Traditional mold management uses paper-based registration of mold numbers and location numbers. Mold storage is irregular and can be found. Random stacking and untimely delivery of warehousing operations can easily cause registration errors, loss of records, management confusion, and extremely inconvenient search.

How to use high-tech means to strengthen the safety and quality management of the mold industry market, supplier management, and reduce operating costs, so that the company’s various data can be collected and tracked in real time and effectively, and to provide visualized real-time data for management, which is corporate management Mold urgently needs to be addressed.

RFID technology has the characteristics of fast reading speed, non-contact, multi-target recognition; in terms of physical characteristics, RFID technology has the advantages of waterproof, high and low temperature resistance, bendable, no mechanical failure, long life, and resistance to harsh environments; in terms of data In terms of storage, RFID technology has large information storage capacity, readable and writable data, and can be updated at any time, and each tag has a unique ID number. Technology with such characteristics is the most suitable mold management solution.

The mold management site installation situation is generally more complicated. If you want to manage these molds well, you must choose appropriate hardware equipment as support. Most molds are made of metal. If you want to manage these molds well, the electronic tags used in the metal environment are The most suitable choice; Shenzhen Jinruiming Technology Co., Ltd. has a variety of UHF metal environment electronic tags and RFID UHF multi-channel readers, and they can cooperate with each other in mold management to achieve good results.

Utilizing the unique ID number of the RFID UHF tag, it corresponds to the mold one-to-one, and writes the mold information into the tag, including mold type, number, production date, mold location, model inventory, processing materials, etc. The RFID electronic tag on the mold is read by Jin Ruiming’s RFID UHF multi-channel reader, and the read information is transmitted to the application system for verification, making judgments, and realizing rapid mold search.

Benefits of using RFID technology to manage molds:

1. Provide the mold storage status in the warehouse, such as available, pending repair, obsolete, etc., to improve search efficiency.

2. A detailed record of the use history of the mold, such as the very important total number of stampings, helps to analyze the cause of mold wear, and evaluate the life of the mold.

3. Detailed records of each set of mold maintenance data, mold use precautions, such as mold loading conditions and which machinery to use, etc., can quickly and accurately know the matching molds required to produce a product.

4. Quickly and conveniently calculate the actual material of each mold, the cost of each process and the cost of outsourced processing, etc., strengthen control and improve work efficiency.

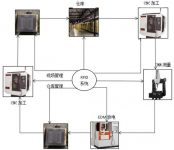

2. System introduction

The entire RFID mold electrode management system is divided into six parts:

1. CAM and warehouse matching system

CAM is the source of information, through UG to export the electrode name, running point value, quadrant, shape, area, pattern, material, spark position, etc. into the system, and match it with the electrode warehouse to bind the electrode Blank;

?Upload the programs and formulas prepared by CNC programmers to the path set by the system through your user name and password;

2. Electrode warehouse management

?The installation of the label on the electrode holder;

? The blank is bound to the fixture, and the height of the electrode holder and the blank is measured;

? Electrode warehouse: standardize the placement of electrode holders, easy to find and inventory, track the service life of the fixture, promptly remind the replacement of the positioning piece and the recycling of the management material, improve the utilization rate of the blank, and manage the in and out of the fixture electrode;

3. CNC workshop system

? By scanning the label on the electrode holder, the CNC program is automatically loaded to realize the functions of stringing programs, reducing the number of tool changes, automatic topping, and simultaneous processing of multiple electrodes, which greatly improves the work efficiency of CNC workshop workers and the rate of machine tool transfer;

?Preview the program list;

4. CMM workshop system

Ø One-key scanning measurement by scanning the label on the electrode holder;

?Automatically determine and save the measurement results, reduce human misjudgment, automatically print the measurement report, and save the offset data in the database;

5. EDM workshop system

?Summary of discharge rules;

The discharge rules are imported into the solution system and into the system of the EDM machine tool;

?Generate the electrode discharge program by scanning the label to reduce the number of points in the discharge process;

6.Web background management system

?System parameter setting;

Permission module settings;

?Log management

?Data addition, modification, deletion, query, and preview;

Open up the information flow from the mold design to the manufacturing process, improve CNC machining efficiency, reduce CNC machining personnel, reduce CMM measurement personnel, and increase the rate of migration of EDM machine tools.

[ad_2]