Application of Radio Frequency Identification Technology in Logistics Industry

[ad_1]

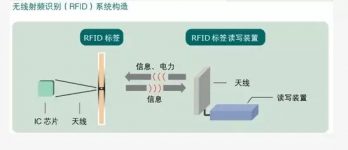

RFID is a communication technology that uses radio signals to identify specific targets while reading and writing related data, without establishing mechanical or optical contact between the identification system and specific targets. The radio signal is an electromagnetic field tuned to a radio frequency to transmit data from the label attached to the article to automatically identify and track the article. Unlike barcodes, radio frequency tags can be embedded in the tracked object.

Recently, many logistics distributors pointed out that the use of RFID technology is a “very important thing.” Because of the special distribution requirements of some customers, the advantages of using RFID to meet these special distribution requirements have emerged. Some logistics companies first adopted RFID logistics and distribution technology, which can give them an advantage in competition with other companies. So, what applications and benefits does radio frequency identification technology have in the logistics industry?

In the retail industry, RFID can improve retailers’ inventory management, realize timely replenishment, effectively track transportation and inventory, improve efficiency, and reduce errors. At the same time, smart tags can monitor the validity of certain time-sensitive commodities; stores can also use the RFID system to automatically scan and charge at the checkout counter. RFID tags in the sales link of the supply chain terminal, especially in the supermarket, avoid manual intervention in the tracking process, and can make the generated business data reach 100% accuracy.

In the warehousing link, in the warehouse, RFID technology is the most widely used to deposit and withdraw goods and inventory inventory, and to automate operations such as inventory and retrieval. Receiving, picking up, and shipping plans formulated by combining RFID technology with the supply chain planning system not only enhances the accuracy and speed of operations, but also improves service quality, reduces costs, saves labor and inventory space, and saves labor and inventory space. Reduce the loss caused by product misplacement, misdelivery, theft, damage and inventory, shipment errors in the entire logistics process. Using RFID system for intelligent warehouse goods management, RFID completely effectively solves the warehouse related to the flow of goods Information management.

In the transportation link and transportation management, RFID tags are affixed to goods and vehicles transported in transit, and RFID receiving and forwarding devices are installed at some checkpoints of the transportation line. In this way, after receiving the RFID tag information in the receiving device, it is uploaded to the communication satellite along with the location information of the receiving place, and then transmitted to the transportation dispatch center by the satellite, and sent to the database.

In the logistics distribution and distribution link, the use of radio frequency technology in the distribution link can greatly accelerate the speed of distribution and improve the efficiency and accuracy of the picking and distribution process, and can reduce labor and reduce distribution costs. The system checks the read information with the shipping record, and all possible errors can be detected, and then the RFID tag is updated to the latest product storage location and status. Inventory control is accurately managed, and even information such as how many containers are currently in transit, the origin and destination of the transshipment, and the expected arrival time can be accurately understood.

[ad_2]