Little Bee helps Sinotrans to build an RFID warehouse management system

[ad_1]

business background

China is one of the countries with the fastest development of air transportation in the world. With the encouragement of national policies and the successive promulgation of Minhang cargo regulations, Chinese airlines vigorously develop air cargo transportation business, and continue to expand and improve the airport’s cargo warehouse and other infrastructure. The construction of my country’s aviation industry has actively promoted corporate reforms and further regulated and promoted the development of China’s air transport industry.

In this context, various airlines are actively developing air cargo business, but they have encountered many problems in this process, such as delays in information construction, lack of information technology, unbalanced round-trip cargo sources, and integrated air cargo and air-ground connections. Unsatisfactory wait for these problems.

Brief Introduction of Sinotrans Tianjin Co., Ltd.

Sinotrans Tianjin Co., Ltd. was founded in 1951 and belongs to Sinotrans Co., Ltd. After restructuring and restructuring in 2002, it became a large-scale integrated logistics enterprise integrating international freight forwarding, shipping agency, supply chain logistics, container yard, and warehousing services.

Project demand point:

After years of accumulation, Sinotrans already has an air transportation system. However, in Sinotrans Tianjin Co., Ltd., especially in the warehouse management area, there are the following series of problems:

1. Inbound management: There is no complete placement plan for the inbound goods, and the information system does not have information on the inventory location;

2. Inventory management: there are too few inventory counts, and there is no information record of the moving position of the goods;

3. Outbound management: wrong goods, searching for goods, releasing goods without customs release information;

solution:

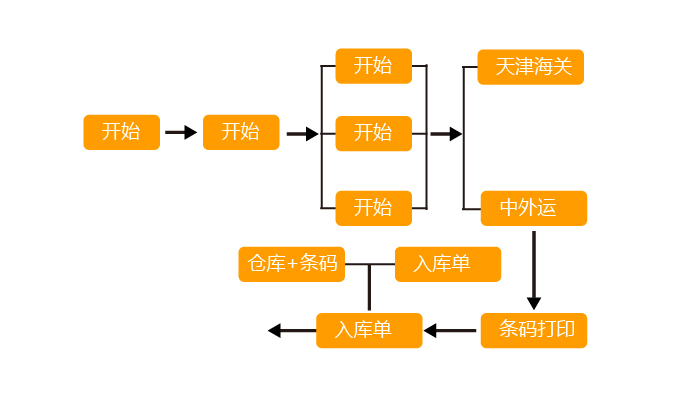

1. Project research phase

The focus of the research work is to be familiar with the deployment of the entire company’s office environment and the business process of the import operation department. Among them, the business investigation of the import operation department is the main content of the investigation, and corresponding solutions are given to the needs of customers for warehouse management.

2. Business Process Analysis

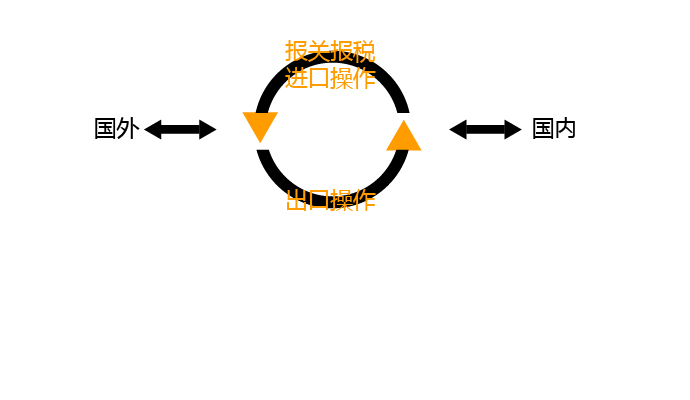

The customs warehouse of Sinotrans Import Operations Department is a logistics distribution warehouse. The main contracted business is the supervision of imported goods and customs declaration and tax declaration business in Tianjin Customs.

3. Formal plan

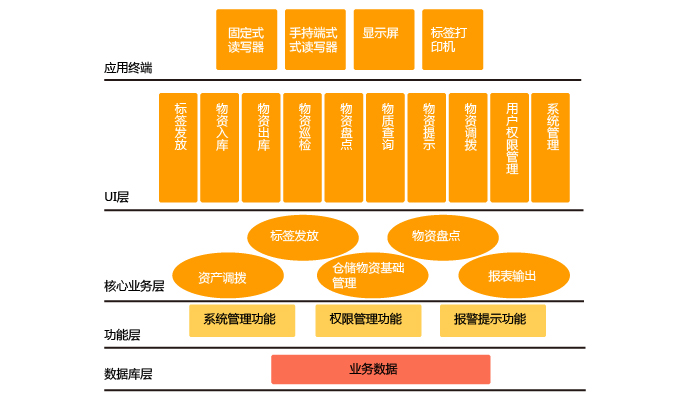

According to the previous investigation and understanding of the process, we provided Sinotrans Tianjin Co., Ltd. with a warehouse management system based on RFID technology, which is composed of hardware and software.

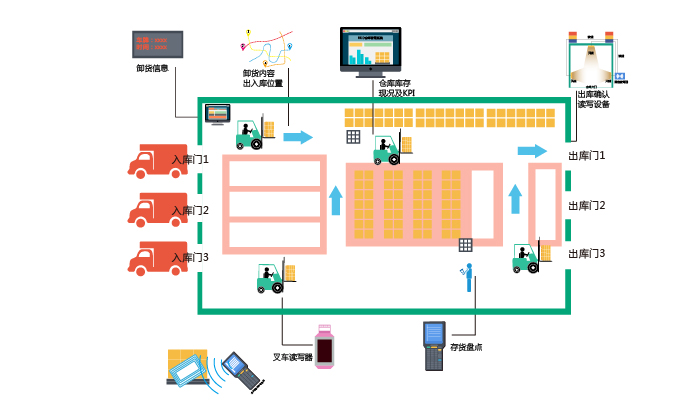

The main feature of the warehouse management system based on RFID technology is that it can recognize multiple tags at a time and quickly and automatically recognize it at a long distance. According to the inventory problem of Sinotrans Customs, this solution mainly solves the inventory and outbound management. The hardware platform of the RFID warehouse management system is composed of fixed readers, handhelds, electronic tags, antennas, mobile readers, mobile display terminals and other equipment.

4. Hardware deployment

While the software system is being developed, the hardware deployment part is also being carried out simultaneously:

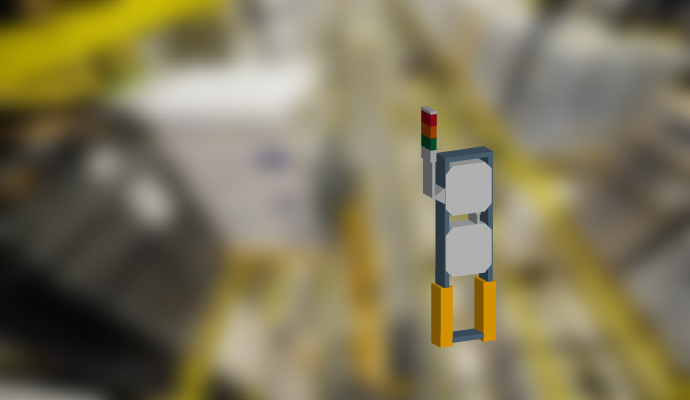

1. Fixed reader and antenna settings

The RFID reader set at the door is accompanied by a warning light. Once the number of passes does not match the system, the upper alarm will give an alarm to notify the operator in time to avoid data problems in the warehouse.

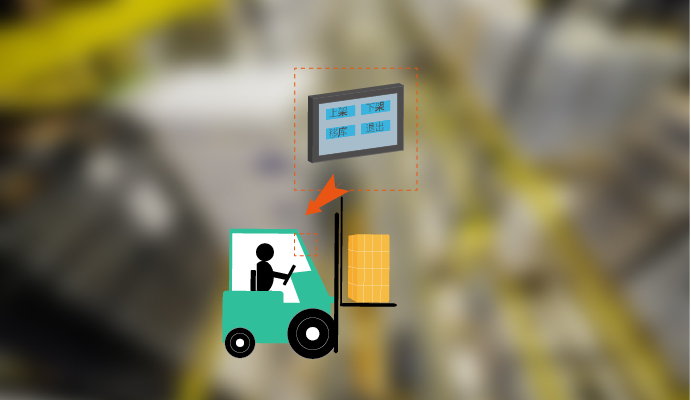

2. The touch panel installed on the top of the forklift, the forklift worker clicks on the system on the screen to perform the next operation

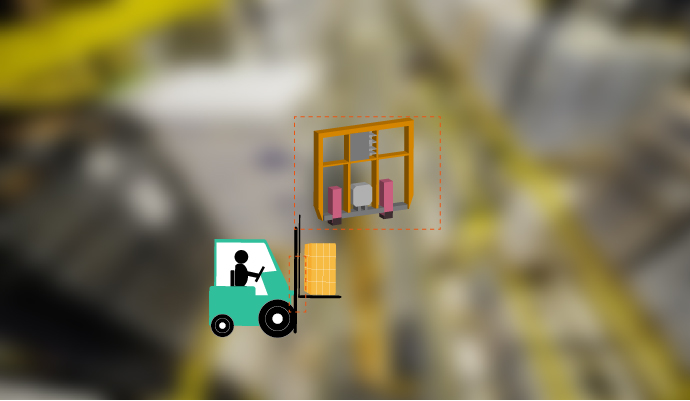

3. Forklift RFID hardware configuration, the black on the top is the fixed reader, and the antenna below. After the cargo tag is loaded by the forklift, the antenna automatically reads the cargo information.

The RFID warehouse management system of Sinotrans Tianjin Co., Ltd. conducts all-round automated data collection on all aspects of warehouse management, such as: arrival inspection, warehousing, outgoing, allocation, shifting, and inventory counting; at the same time, it ensures warehouse management. The speed and accuracy of data input in each link ensure that the company understands the operation of the warehouse in the first time and does a good job in warehouse management.

[ad_2]