RFID- cold chain transportation

[ad_1]

Cold chain transportation refers to the transportation that keeps the transported goods at a certain temperature throughout the entire transportation process, whether it is loading, unloading, handling, changing transportation methods, or changing packaging equipment. The cold chain transportation method can be road transportation, water transportation, railway transportation, air transportation, or a comprehensive transportation method composed of multiple transportation methods. Cold chain transportation is an important part of cold chain logistics. The main objects of cold chain transportation are: medicines such as vaccines and blood products; fresh foods such as quick-frozen foods, meats, etc., cold drinks, vegetables, fruits, and aquatic products.

RFID temperature tag is a type of tag that closely combines digital identification and temperature measurement. It uses digital identification to complete the identification of materials and at the same time measure and record the environment in which it is located. This article has made some in-depth discussions on RFID temperature tags in the field of modern cold chain transportation.

Introduction to the status quo of cold chain transportation

The cold chain transportation rate of food in the United States, Japan, and Western European countries is 80% to 90%, while that of Eastern European countries is about 50%, while that of my country is only about 10%. It is understood that the waste caused by discarding rotten food in my country last year reached 70 billion yuan, accounting for as much as 20% of the total food production value. This waste is mainly due to the lack of a cold chain transportation system, which causes some foods to be discarded during transportation because they cannot be kept fresh for a long time. For medicines, temperature deviation will cause the deterioration of the quality of the medicines, and even toxic mutations; the freezing of peptides and protein drugs will reduce the potency, affect the efficacy, and lose the freezing activity of the vaccine, and even produce harmful toxins.

For cold chain transportation, we must know its temperature. The traditional monitoring method is to use a temperature recorder to measure and record the temperature of the entire carriage, that is, each transport vehicle puts one or more temperature recorders to measure and record the transportation. For the temperature in the process, when the goods reach the transportation destination, the temperature recorder and the computer are connected to the computer to import the data into the computer, and then perform data statistics and analysis, such as finding the maximum value, minimum value, and curve trend. Traditional temperature recorders are expensive, bulky, unable to measure the temperature of a single cabinet, unable to automatically identify product information, and require wired connection and manual intervention to export data. They cannot meet the requirements of temperature monitoring in the modern cold chain transportation industry. .

In addition to temperature, the cold chain transportation industry also faces a problem of distinguishing responsibilities. A person in charge of cold chain transportation once expressed this feeling: “Our company’s refrigerated transportation and cold storage are controlled in accordance with the temperature of food standards, but we receive from suppliers. When the goods are delivered, it is often found that the supplier does not operate the goods according to the corresponding temperature. In this case, we will re-freeze the goods and then transport them to various stores, but once there is a problem in the store, the customer will transfer the responsibility to us On the head.” On the other hand, for some companies that are not very responsible, in order to save costs, customers turn on the cold machine when loading the goods, and turn off the refrigeration equipment during the transportation process, which is almost the goal. When the cold machine is turned on at the local time, the whole process cannot be turned on. When the goods are delivered, although the surface of the goods is frozen well, it has actually deteriorated. Therefore, the problem of distinguishing responsibilities is also a problem that needs to be solved urgently, that is, when the product quality does not meet the requirements when the product arrives at the receiver, it must be determined whether it is caused by the temperature of the cargo transportation that does not meet the requirements. It is out of this concern that some large domestic pharmaceutical companies would rather spend a lot of high cost to build a logistics company than use a third-party cold chain transportation company. Obviously, the cost of doing so is expensive.

Application of temperature label in cold chain transportation

As an emerging automatic non-contact identification technology, RFID has been rapidly developed at home and abroad, and the introduction of RFID technology into the field of logistics applications has become a hot spot. Designed and developed a tobacco logistics sorting system based on R FID technology, which realized the automatic sorting operation of tobacco products; based on the demand analysis of the logistics tracking system of automobile manufacturing enterprises, proposed a logistics tracking management system based on RFID; and a series of applications, the above applications RFID is only used as an identification to identify products. For the modern cold chain transportation industry, not only the identification of its products must be concerned, but also the temperature value associated with it. The temperature label has both digital identification and temperature information, which can meet the requirements of temperature monitoring for cold chain transportation.

The RFID temperature tag provides energy for temperature collection and storage through the built-in battery, and can independently complete the temperature collection and storage. When it enters the effective recognition range of the card reader, the energy is obtained through the excitation of the card reader to complete the data exchange. This temperature tag has extremely low current consumption.

The RFID temperature tag complies with the ISO/IEC 18000 standard UHF temperature tag.

The use process of RFID temperature tags is as follows: when the product is out of the warehouse, according to the needs of goods transportation, the temperature tag is attached to the surface of the object to be tested, the temperature range is set, the temperature tag will automatically record the temperature, and the collection cycle is uninterrupted in the preset Record the ambient temperature value, and the handheld terminal will display it in real time, and an alarm will be issued if the temperature exceeds the temperature range; during the cargo transfer process, the handheld terminal will read the information and temperature of the RFID tag of the cargo box to ensure the effectiveness of the goods; in the product storage , The handheld terminal can conveniently, quickly and accurately sort the goods according to the RFID tag information while verifying whether the temperature meets its storage temperature. When goods that meet the storage temperature requirements are stored in the warehouse, the temperature data will be synchronized into the database. The entire logistics During the process, the entire temperature record was realized to ensure product quality.

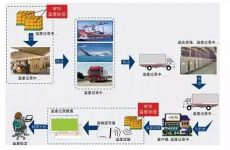

The application process is shown in the figure below:

Application flow chart

The RFID temperature tag can collect and record the environmental temperature value of the transported goods. It can be used to record the environmental temperature of the goods during the production, storage, transportation, sales, and pre-consumption stages, so as to realize the temperature traceability of the whole process, so it can effectively distinguish the accident responsibility problem. At the same time, it is suitable for the transporter and the entrusting party of the goods; RFID temperature tags are more suitable for cold chain vehicle temperature monitoring due to its real-time, large number of tags read at the same time, and good scalability, so as to ensure the quality of the goods.

[ad_2]