RFID mine transportation control makes efficiency more efficient

[ad_1]

The development of mine assets is an important operation link of resource-producing enterprises. It is an important task for enterprise managers to ensure reasonable and scientific mining of mine resources and ensure safe production measures for mining and transportation operations. Generally, billing is based on the number of times the transport vehicle enters the mine. In the past, the billing method relied on manual registration, which is prone to errors and low registration efficiency. When the vehicle is busy, it will cause unnecessary congestion. Due to the harsh environment in the mining area, it is difficult for staff to register vehicles outdoors for a long time. RFID technology enables the mine vehicle entry and exit management system to automatically register entry and exit, effectively improving the efficiency of management.

RFID technology meets the requirements for safe transportation management of mining vehicles. How to ensure accurate coal measurement and transportation safety in the coal industry to ensure that coal is not lost inside and outside the field has become an urgent problem for major coal companies to solve.

1. Be able to strictly manage coal stockyard transportation vehicles to ensure real-time control of the real-time status of relevant transportation vehicles inside and outside the coal stockyard and in the driving route (such as: whether it is a legal vehicle, eliminate license plate vehicles, and the system constantly tracks and records the entry of mining vehicles Field, playing time, weighing situation, whether the route of travel meets regulations, etc.).

2. Ability to monitor the operation of the ground scale (weighbridge). When coal materials are transported, a ground scale is usually used to weigh the bulk materials in a “gross-tare” method. The vehicle can be uniquely identified and automatically identified. It can automatically grasp the material transportation and inventory data from the management software, and at the same time, prevent illegal behaviors such as “one truck passing two times, large truck passing by and small truck returning to the skin”.

3. It can wirelessly connect the metering network management system and the platform scale weighing system to form an intelligent management system. The automatic weighbridge automatically obtains data and feeds back to the central server from time to time to establish connections with various departments such as procurement, inventory and production to form a complete measurement terminal system, optimize the internal management process of the enterprise to the greatest extent, and increase work efficiency.

4. A query monitoring system can be provided, so that relevant personnel can monitor and track a certain coal material vehicle at any time through the management system.

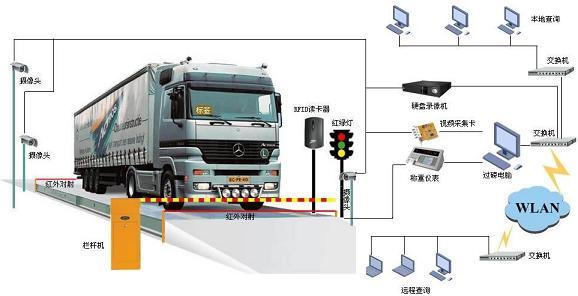

The use of RFID technology to manage related transportation vehicles mainly includes the following parts: label issuance and binding registration with corresponding vehicles. Vehicle entry and exit identification, through the weighbridge, coal yard, key point route identification inspection vehicle handheld or vehicle-mounted equipment inspection.

Realize local and remote management through network technology

(1) A wire network or wireless network is set up so that the network covers the operation area of the entire stockyard, and all operation data can be transmitted in real time through a fixed RFID reader. The fixed RFI reader has the functions of accepting operating instructions, confirming whether the operating location and operating materials are accurate, and returning to the actual operating status.

(2) The data interaction of the operating point can be realized through the database and the computer network, which can realize the remote real-time query, statistics, and summary of the operating information of each operating point, and generate various reports.

Aiming at the current shortcomings in business management, adopting a variety of advanced technologies can fundamentally make up for loopholes in management, optimize business processes, improve management levels, and improve work efficiency.

The entire operation process of the coal transport truck

(1) Label issuance: Coal transportation vehicles receive RFID electronic labels through the label issuance office of the back-end management center (divided into two situations: team issuance and on-site issuance). Transport vehicles need to provide meter number, license plate number information, vehicle type, identity information, etc., and the system enters meter number, license plate number, and driver-related information. Vehicles equipped with electronic tags are the only basis for legal transportation of minerals in the future.

(2) Coal transportation vehicles enter the coal yard to weigh: the reader will automatically identify whether the RFID electronic tags in the car are legal? Manually check the vehicles that have not detected the electronic tags to prevent illegal transportation vehicles from transporting coal privately; if a vehicle is detected When there is a legally authorized electronic tag in the vehicle, the vehicle can enter the platform for weighing, and record the vehicle’s entry time, gross weighttare weighing data and weighing time; if an unauthorized vehicle is detected with an electronic tag in the vehicle , The reader will automatically start the alarm device, give an alarm, and notify the relevant management personnel to deal with it until the problem is eliminated.

(3) Coal transportation vehicles enter the site for coal loading and secondary weighing: legal coal transportation vehicles enter the coal yard to load coal. After coal is loaded, the vehicles enter the secondary weighing yard for weighing, and the reader will also record the vehicle’s entry time, Departure time, total weight of coal truck and coal

After the coal loading of the transportation vehicles is completed, some legal vehicles did not enter the secondary weighing field in accordance with relevant regulations, but drove directly along the avenue, causing great economic losses to the enterprise and the country. After fully considering various factors, the design In order to install fixed readers or hand-held readers at the fork of the transportation road for inspection, the vehicle trajectory is formed in the system. Facilitate access to prevent the theft of coal resources of the country or enterprise by legal coal trucks.

Use advanced RFID radio frequency products to cooperate with IoT technology solutions to effectively manage related transportation vehicles. The ultimate goal is: to achieve an efficient and reliable management platform, to grasp the coal transportation status of mining enterprises in real time, and to improve the company’s understanding of coal transportation. To prevent man-made management loopholes and corporate property losses.

[ad_2]