RFID technology to create intelligent access to grain depots

[ad_1]

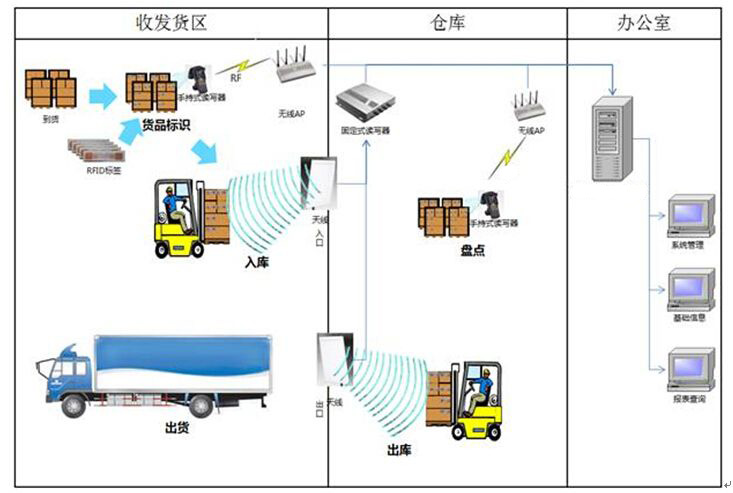

With the rise of “Internet +” technology, the food industry has gradually moved towards informatization and electronics. Increasing the management efficiency of grain depots through informatization has been paid more and more attention by the state and grain storage enterprises. Therefore, the concept of “informatization construction of grain depots” came into being. The construction content of the grain depot information system is divided into four business domains: “grain depot business management”, “intelligent storage and storage”, “intelligent storage and storage”, and “intelligent security”. This article mainly provides an upgraded solution for the “intelligent storage and storage” plan. RFID technology creates intelligent access to the grain depot.

1. The current status and problems of traditional grain depots in and out of the depot

Grain purchase and storage, sales and export are not only the core business of the grain depot, but also the difficulty of supervision. Especially in the peak season of grain harvesting, there are often many disadvantages in manual operation methods, such as irregular processes and many blind spots in supervision, which are mainly manifested in the following three points:

1. Manually record data, and information is not shared

Manually fill in the documents for each link, it is difficult to avoid mis-filling or artificial tampering, which encourages violations such as “gratuity”, which leads to inconsistencies in the information of the previous and subsequent links, inconsistent accounts, and distortion of quantity and quality;

2. Grain trucks are not supervised one by one, and information is not recorded in real time

The trajectory of food delivery vehicles cannot be continuously monitored throughout the entire process, and there are blind spots. It is difficult to prevent fraudulent behaviors such as manipulating the number of vehicles in the warehouse. At the same time, it is impossible to record the information of each link of each vehicle in real time, and it is impossible to trace weighing, quality inspection, loading and unloading at any time. , Grain payment settlement and other information, even if the grain depot needs statistical analysis, audit and supervision, it lacks true and accurate data, which makes cheating people feel confident;

3. Automation has not been realized, and it is difficult to maintain fairness in human-to-human supervision

Manual operation is not only inefficient in operation, but it is inevitable that people-to-person supervision methods are driven by profit, which makes the inbound and outbound operation process irregular, the implementation of national policies and standards is not in place, it is difficult to sell grain, and the quality of inbound grain is low.

The above-mentioned reasons make the phenomenon of “checking A and selling B”, “changing the car and returning the skin”, “changing the license plate”, and “stealing the sample” frequently in the grain collection, which will cause immeasurable losses to the country and grain storage enterprises in the long run.

2. Intelligent warehouse-in/out based on “one card”

Based on the above problems, the paperless office method represented by the “grain depot all-in-one card” has emerged. The grain depot all-in-one card is made into a card the size of a bank card, which links the vehicle and personal information related to the food seller to the card. Here, with this card, customers who sell grain can complete the entire process of entry registration, sampling, weighing, loading and unloading confirmation, deduction, settlement and payment, and grain transactions, making the acquisition and sales of grain depots the first to enter the information age. But its essence is to replace the original work of manually filling in paper documents, and realize the initial stage of informatization-paperless.

But this card can be exchanged between two cars just like “changing a license plate”, so there is still a big loophole from the supervisory point of view.

Third, the application upgrade of the magnetic vehicle electronic label intelligent warehouse in and out solution

Active monitoring magnetic vehicle electronic tags are low-power, multi-band electronic tags, highly integrated, wireless communication, RFID functions, pressure detection, magnetic field detection and other functions. It can be compatible with all-in-one cards, license plate recognition, two-dimensional codes, disposable electronic tags and other applications, realizing the dual role of electronic communication and vehicle supervision.

The magnetic vehicle electronic tag cannot be separated from the vehicle. The grain truck is attached to the vehicle when it enters the factory, and intelligent identification terminals are installed in the sampling, inspection, weighing, and storage links to automatically identify the vehicle information and complete the automatic information interaction , To realize the automatic association of grain trucks with samples, inspection results, and weighing results. Tracking the food trucks step by step, so that there is nowhere to hide the interference and cheating methods such as changing cars, stealing samples, checking A and selling B, etc.

At the same time, the vehicle electronic tag can be monitored for pressure and magnetic field strength, that is, once the tag is moved or removed, the smart interactive terminal can send out an audible and visual alarm to stop the vehicle’s food sales, and realize all the items carried by the vehicle, such as food data ( Quality, weight) are uniquely related to the seller’s information, which eliminates the possibility of cheating from the root cause and realizes the active monitoring of cars to people.

[ad_2]