Using RFID technology to realize the automatic management plan of warehouse management personnel picking up goods

[ad_1]

Personnel permissions in warehouse management systems are currently a hot research topic. A good management system considers the division of permissions from multiple aspects; if it is not appropriate, it will not only cause system instability, but may also cause important data information leakage. . From a security perspective, in general, we will follow the principle of least authorization when designing programs; that is, granting the minimum permissions required by the program code in the least amount of time, unless the program requires it, otherwise it will not allow the use of administrator permissions to run the application . In a multi-functional information system integration platform, it contains multiple sub-modules, and each module may need its own set of special permission system. Generally, software developers can only modify the code to meet the needs of users. In most cases, the permission system is usually set by the user in the initial stage of implementation, so designing a sound permission scheme is particularly important for the information system integration platform.

So in the modern highly integrated cargo warehouse management, how to arrange the personnel authority problem reasonably? For a large freight warehouse, if the personnel’s pick-up authority can be properly arranged, then it can greatly reduce or even avoid the delivery of goods and mistakes. The situation of the loss of goods and goods; so as to realize efficient automatic warehouse management. This paper proposes an automated personnel authority management strategy based on RFID technology, relying on the combination of software and hardware, to achieve the automated management of warehouse personnel picking up goods.

1 Scheme analysis

The entire automated warehouse management personnel pick-up authority program is based on two foundations for in-depth research.

1) The core technology of the radio frequency identification system is the realization of the anti-collision algorithm for multiple access. There are two main communication methods in the RFID system: ① The wireless broadcast method, that is, there are multiple transponders in the reading range of a reader, and the data stream sent by the reader may sometimes be received by multiple transponders. ②Multiple access mode, that is, multiple transponders transmit data to the reader at the same time within the range of the reader. The former is not the focus of the author’s consideration, while the latter will cause communication conflicts and data collisions. At present, there are basically four solutions: Space Division Multiple Access (SDMA-Space Division Multiple Access), Frequency Division Multiple Access (FDMA-Frequency Division Multiple Access), Time Division Multiple Access (TDMA-Time Division Multiple Access) and Code Division Multiple Access (CDMA-Code Division Multiple Access). Considering factors such as RFID system communication form, power consumption, system complexity, and cost, the TDMA method is selected to implement the anti-collision mechanism in the radio frequency identification system. The anti-collision algorithm based on TDMA is divided into: bit-based binary search algorithm and time slot-based ALOHA algorithm; this solution uses binary search algorithm to solve the anti-collision problem.

2) The basis of the radio frequency identification system-the design of the EPC data encoding format. The choice of EPC data coding scheme will determine the convenient realization of EPC data collection. In this scheme, the design of EPC data encoding format includes two parts: ①The design of personnel delivery authority encoding. ② EPC code design for cargo identification. At present, there are 13 EPC coding schemes, and its general structure is composed of a hierarchical, variable-length header and a series of digital fields as shown in Figure 1. The header defines the total length, identification type and EPC coding structure, which can also include its filter value; the length of the header is variable.

Figure 1 General structure of EPC data encoding

2 Scheme design

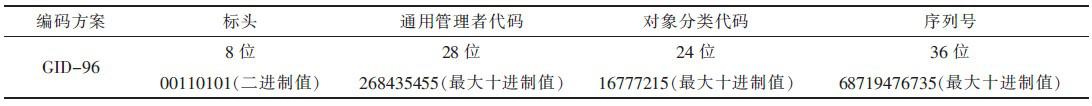

The plan design includes two parts: cargo coding plan design and delivery personnel authorization plan design. In the part of cargo coding scheme design, according to the needs of system design, one of the GID-96 universal identifiers is adopted. It does not rely on any existing known specifications and identification schemes, and uses a 96-bit EPC code consisting of 3 fields (general manager code, object classification code, and serial number). After adding the header, the uniqueness of the EPC namespace is guaranteed. Its format is shown in Table 1.

Table 1 General identifier (GID-96)

Among them, the general manager code is used to identify an organizational entity, such as a company, manager, etc.; it is responsible for maintaining the number of the back field; the object classification code is used to identify the type or type of items under the general manager code; the serial number is used To identify each specific object under the object classification code. The codes of the three are unique, and they are not allowed to be repeated under the same type. It can be seen from this coding format that the object classification code part represents the type of materials stored in the warehouse; it also represents the type of materials stored in the warehouse. When a large freight warehouse has multiple pick-up personnel, the code also gives A reasonable way to distribute the rights of picking personnel.

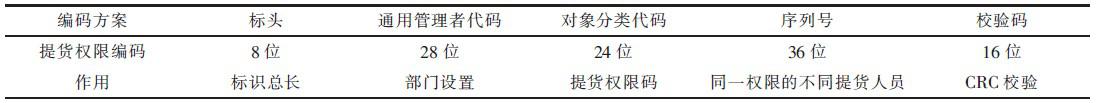

In view of the fact that the pick-up personnel are only for a specific logistics company, their pick-up rights rarely involve external aspects; and considering the efficient operation and robustness and stability of the warehouse management system, in the design part of the pick-up staff’s permission coding scheme, separate delivery personnel are used Establish a set of custom permissions encoding format. The encoding format is still custom-designed based on GID-96, the purpose is to make it easier to implement and more efficient when searching the database in batches. Its encoding format is shown in Table 2.

Table 2 Authorization code of pick-up personnel

The general manager in the code is divided into two types: the board of directors with the highest authority, and the warehouse management department in charge of different pick-up personnel; they are given different codes to indicate. In the object classification code part: all the object classification codes under the directors department are set to 1, which means that the directors have the highest authority and can check the inventory of various materials in the current warehouse and extract various materials in the warehouse. Different pick-up personnel in the warehouse management section have different object classification codes, which also means that different pick-up personnel have different types of goods. In the serial number part, according to the number of personnel N, the high-level use method is adopted: N=2M-2 (where M<36, all 0s and all 1s are not used, so it must be reduced by 2); the remaining 36-M digits are not considered for general use Managers and objects are classified, and all of them are set to 0. The check code adopts cyclic redundancy check (CRC). Its greatest advantage is the high reliability of identifying errors. Even when there are multiple errors, only a few operations are required. The error can be identified; and the 16-bit CRC can check the data integrity of the 4-kilobyte data block, which can easily meet the needs of the RFID system.

3 Scheme realization

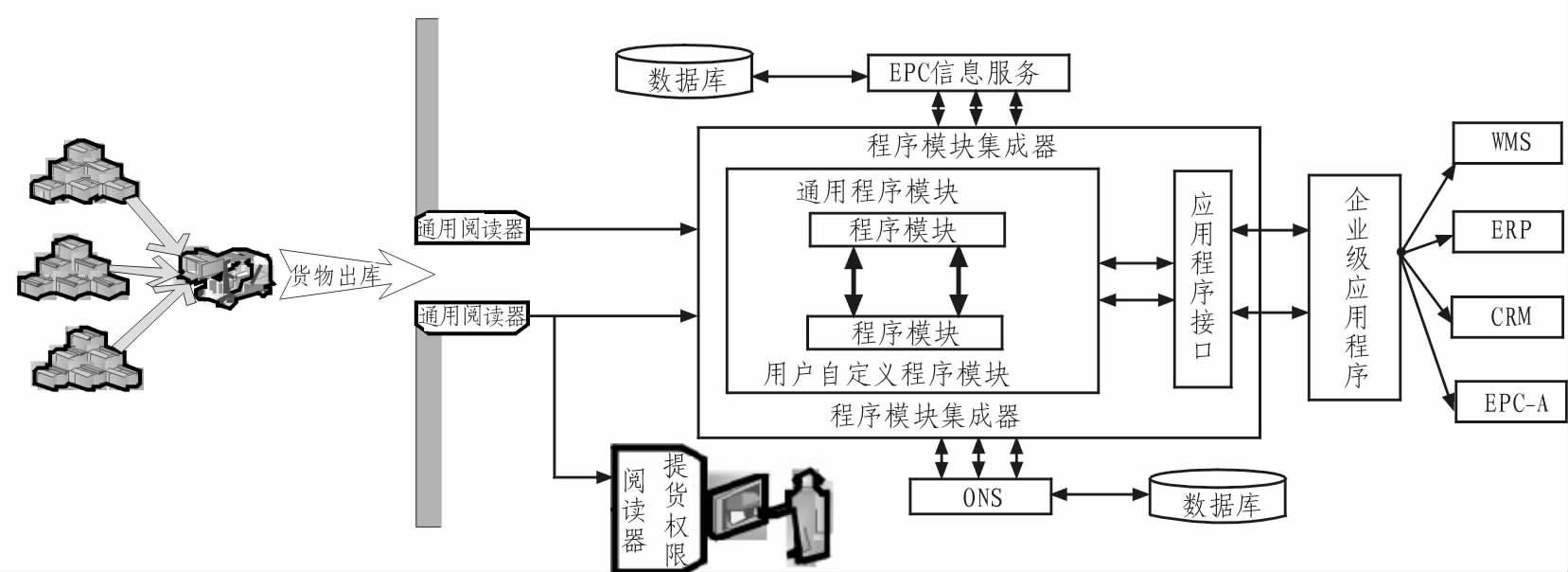

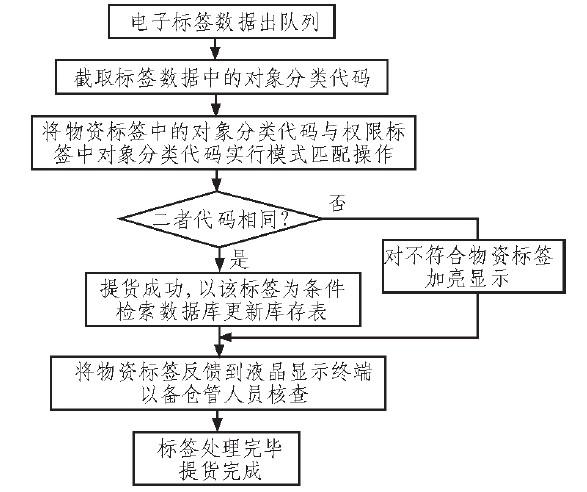

First, when different types of materials are shipped out of the warehouse, they are implemented by picking personnel with different permissions. The authority of the pick-up personnel is represented by the “object classification code” in the EPC code. The pick-up personnel first read the pick-up authority carried by themselves by a dedicated authority reader. After the system obtains the electronic label data, it intercepts and stores the “object classification code” in the authorization label data into a private variable through an interception instruction. When the mentioned goods are out of the warehouse, the reader obtains the electronic label of each goods, and transmits the collected electronic label to the system through the middleware. During the transmission process, two operations are required: 1) Intercept the object classification code in the electronic label of the goods and the object classification code in the electronic label of the picking personnel authority for pattern matching. When the matching is successful, the electronic label data of the material is used as the search condition to traverse the inventory table in the database: when the matching is unsuccessful (That is, the object classification code in the label of the picked up goods is different from the object classification code in the authorization label of the pick-up personnel), indicating that the pick-up personnel does not have the authority to pick up the item, then the electronic label of the goods will be fed back to the LCD terminal, And it is highlighted; to prepare for warehouse management personnel to check and check. 2) When the goods are picked up successfully, the goods will be shipped out; at the same time, search the database with the electronic label data of the goods as the search condition, update the current database storage material inventory table; ensure that the quantity of goods in the inventory table corresponds to the warehouse one-to-one. This update operation is somewhat similar to the cargo storage operation. The entire delivery operation process is shown in Figure 2.

Figure 2 Flow chart of pick-up operation

EPC data collection part: The operation of the electronic label data collection of the outbound materials and the personnel authority electronic label data collection is “asynchronous”. First collect the authorization label data of the picking personnel, and then perform pattern matching with the electronic label data of the collected materials out of the warehouse. The reason for this is that the database that stores the information of the warehousing materials and the database of the personnel authority information are managed separately, which can effectively ensure that the authority information of the pick-up personnel is not leaked or stolen, and prevents the loss of warehousing materials.

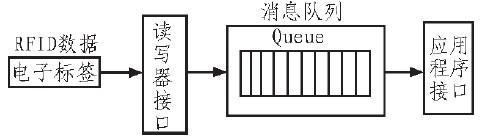

Application module part: In view of the fact that multiple readers are working at the same time, the number of tags read every second is very large. A buffer is usually used to temporarily store the electronic label data. The electronic label data is stored in the form of a message queue, and its structure is shown in Figure 3.

Figure 3 EPC data queue

In order to facilitate understanding, the author only takes any electronic tag in the EPC data queue as an example to demonstrate the entire processing process. First, the electronic label data is out of the queue and enters the application program interface. Figure 4 is a flowchart of the entire process.

Figure 4 Partial processing flow chart of the application program

4 Scheme verification

In view of the fact that EPC data acquisition is implemented in the hardware part, I won’t go into details here. Simulate the collected EPC data to verify the plan. The collected EPC data is stored in the EXCEL table in the form of a two-dimensional table, and the current warehousing material inventory table is stored in the ORACLE database for batch retrieval of the database. Since the batch retrieval database has very high requirements for query response time, the idea of dividing-sampling-matching is adopted here. The materials have been simply classified during the warehousing operation, so in batch retrieval, only the first one in the inventory table of each type of warehousing material needs to be matched. When the object classification code part is consistent with the stored records in the current inventory table, the serial number is matched; the most important advantage of this method is: one interception, multiple use. The object classification code of the batch retrieval data database will be used again when checking the personnel’s delivery authority, and only a temporary variable is needed to temporarily store the code: greatly reducing the interception workload and shortening the processing time.

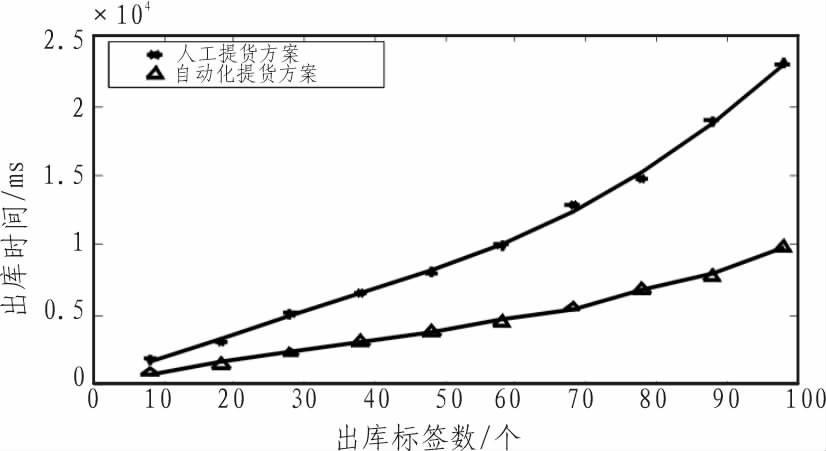

In view of the above-mentioned research, simulation is carried out in three environments in MatLab. Simulation environment 1: Inventory table records are fixed at 1000, outbound label changes: 8 to 100, and the pick-up person is 1 person; the simulation result is shown in Figure 5.

Figure 5 The simulation results of the recognition time of different tags with a fixed number of records

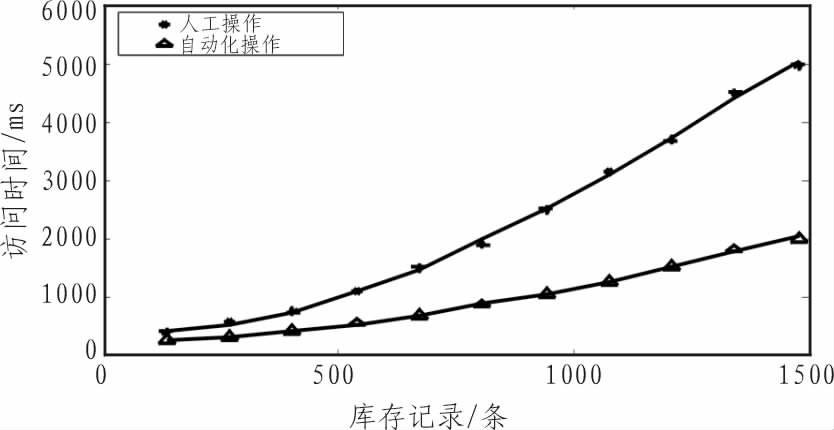

Simulation environment 2: 30 fixed outbound tags, inventory table record changes: 100~1 500, and 1 picker; the simulation result is shown in Figure 6.

Figure 6 The simulation results of the recognition time of 30 tags with different numbers of records

Simulation environment 3: Outbound label change: 20~70, inventory table record change: 150~1 450, picking staff is 1 person; the simulation result is shown in Figure 7.

Figure 7 The simulation result of the number of label records randomly out of the library

It can be seen from the simulation results that this method can correctly process the data; realize the classification and picking management with the object classification code as the core. Compared with ordinary pick-up methods, it shortens the delivery time. By locking the electronic label of the goods, the error of picking up is reduced to a minimum, and the original intention of the program design is achieved. It provides a new idea for modern warehouse picking management.

5 Conclusion

In order to realize efficient and fast modern warehouse management, an automated management plan based on RFID technology for personnel pick-up authority is proposed. Relying on the special EPC codes for the pick-up personnel, the warehouse management personnel’s pick-up rights are reasonably allocated, which solves the problems of slow delivery and incorrect delivery. However, from the perspective of the design authority code itself, the delivery authority scheme has certain limitations. When there are many types of warehousing materials, each warehouse manager only granting the right to pick up one type of goods alone may not be able to meet the flexibility requirements of warehouse management, resulting in waste of warehouse management personnel and increasing the investment cost of warehouse management. This is where the plan needs to be improved in the next step.

[ad_2]