Warehouse management implementation case analysis

[ad_1]

Manual management ills

A certain company has more than 3000 types of raw materials and more than 300 finished products, which are managed by 7 warehouse managers. After the material is received, first mark the material information with half a sheet of A4 paper, register the material card and fill in the material list when entering and leaving the warehouse, and then record it in the Excel spreadsheet on the computer, and update the whiteboard record of the corresponding warehouse area. With the expansion of the company’s scale and the increase in the quantity of materials, the pressure and risks of logistics management are increasing.

Since the warehouse does not use any warehousing logistics software, all material records are manually registered with the name, quantity, specification, and date of entry and exit of the materials. Manual recording has a large workload, and the timeliness and accuracy of the data are completely dependent on the warehouse keeper Work responsibility.

The company’s customers basically use a barcode system to manage materials, requiring the company to print and paste barcode labels according to their requirements before shipping. Manual data recording and label printing work is not only inefficient, there are hidden dangers of error, but also non-value-added behavior, which affects customer relationship management to a certain extent.

In response to these shortcomings, the company’s bar code management requirements are as follows.

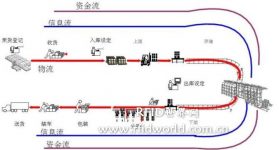

Fully implement bar code automation management for raw materials, semi-finished products, finished products, etc., manage warehousing, outgoing, allocation, shifting, inventory and other businesses to improve management. Purchasing barcode scanners and barcode printing equipment, printing box labels and various business documents to improve the efficiency and accuracy of operations such as warehouse entry and exit. Transform the existing local area network, build WLAN, connect the server of the barcode management system, computer, barcode scanner, printing terminal, etc. through LAN and WLAN, and then import it into the ERP system through the interface program, so that it can process various tasks in real time.

Of course, we must also pay attention to the preliminary work. This includes paying attention to the promotion and training of barcode knowledge, so that employees can value this work ideologically. The application of bar code must cooperate closely with all departments, clarify the responsibilities, authorities and mutual relations of relevant departments and personnel of bar code, and provide necessary technical and operational training for relevant personnel.

Organize employees to discuss and establish bar code management systems, such as bar code generation rules, bar code printing systems, bar code pasting specifications, bar code usage regulations, etc., and continue to improve in the later bar code operation.

ERP before barcode

The combination of bar code technology and ERP software can truly achieve the timeliness, accuracy and traceability of data collection. In view of the need for clear business processes for barcode implementation, it is recommended that the implementation sequence is ERP followed by barcode. Through business process optimization and data correction during ERP implementation, pave the way for barcode import. On the other hand, the implementation and use of ERP requires the entry of a large amount of document data. Automatic barcode recognition and entry replace manual entry, which also provides a strong guarantee for the smooth operation of the ERP system.

The business scope of barcode application includes the following aspects.

The main process: raw materials storage, storage, finished products storage, storage;

Secondary processes: production return material storage, purchase return delivery, allocation (transfer between warehouse and warehouse), warehouse shift (transfer between warehouse locations in the warehouse), inventory, query statistics;

Outsourcing process: outsourcing processing and processing with supplied materials;

Semi-finished product process: workshop processing records to semi-finished product storage to semi-finished product out of storage;

Supply chain matching process: Establish a supplier platform, a company designs the bar code rules, the supplier logs in to the company’s supplier platform, prints the bar code label of the product out of the warehouse, and pastes the bar code label on the outer package or pallet of the part before delivery.

According to the step-by-step implementation strategy, first carry out barcode management on raw materials, then implement finished product warehouses and semi-finished products warehouses, and finally implement supply chain matching.

Raw materials warehousing: The supplier will not be affected in the early stage. When the supplier receives materials, the company will print a barcode label according to the inspection form, and the inspector will paste the barcode on the package or pallet, and then scan it for storage. The barcode should contain information such as the material code, warehousing batch number, quantity, and warehousing location.

Storage of semi-finished products: According to the production order, when the production line is offline, the production operator will print a barcode label and paste the semi-finished product on it, and then scan it for storage.

Finished product storage: Scan the production order and print the barcode label of the finished product. When a package is filled, the barcode label of the packing box will be automatically printed, and the barcode will be pasted to the specified position of the packing box, and then scanned and put into the warehouse.

Standardize the process

Warehousing operation process: Check the receipt of the goods according to the warehousing notification (check the warehousing notification information on the terminal), scan the product bar code, quantity bar code, batch number bar code, and storage location bar code to collect product warehousing information. After the warehousing is completed, the back-end database is automatically updated, and the product inventory records corresponding to the warehouse and location are added.

Raw material requisition out of warehouse: The requisition of raw materials must correspond to the relevant production order in order to calculate the production cost and quality prosecution. Therefore, when releasing the workshop production task, the production order with bar code should be printed. When requisitioning out of the warehouse, scan the production order, get the list of materials needed for this production order, and scan out the warehouse.

Finished product delivery: Automatically retrieve the delivery list according to the marketing department’s invoice, and scan the barcode label of the product packaging box one by one to ensure that the finished product is first-in-first-out. The bar code should contain the key information required by the customer. The fixed information such as the material code is a code segment, and the variable information such as the quantity can be set to another code segment.

Out-of-warehouse operation process: In accordance with the out-of-warehouse notification, issue the inventory products. Scan product barcode, quantity barcode, batch number barcode, and warehouse location barcode to collect product outbound information. After the delivery is completed, the background database is automatically updated, and the product inventory records of the corresponding warehouses and locations are deducted.

Inventory process: Select inventory warehouse and location on the terminal. When the inventory data is saved, the background database is automatically compared, and the difference statistics information is generated and displayed on the terminal in real time, providing verification for the inventory personnel. After the inventory is completed, the inventory difference report is automatically generated in the background for printing and verification.

Number of users: In the early stage, only raw material warehouses are involved, and 20 users are sufficient for purchasing + warehouse management + production requisition. In the later stage, the finished product warehouse will be added. Sales + planning + procurement + warehouse management + production requisition are expected to have 30 users.

With the wireless collection scheme, the system can reflect the storage situation in time. According to a wireless AP signal coverage radius of 50 meters, a 1000 square meter warehouse only needs two APs.

Hardware purchase configuration: barcode scanner + barcode printer. In principle, one warehouse keeper is equipped with a barcode scanner, and several warehouse keeper can be cut after the barcode system runs smoothly. In the early stage, the printing business volume was not large, so a barcode printer was temporarily purchased.

Benefits after implementation

Simply put, the advantages of the barcode system are embodied in the three words “fast”, “quasi” and “saving”. Barcode management is essentially process management, the process is fine and controllable, and the result is naturally correct and effective. Warehouse barcode management has brought huge benefits to a company’s logistics management:

Realize material positioning and quantitative management;

Control raw materials first-in-first-out to avoid human error;

Strictly implement quota picking to eliminate waste;

Real-time control of inventory data, reasonable maintenance and control of corporate inventory, and improve work efficiency and work quality;

The traceability of the product production process is realized through the automatic collection of material batch information.

More importantly, barcodes promote the transformation of a company’s management model, from traditional management based on experience to management based on precise digital analysis. Post-management is transformed into in-event management and real-time management, which accelerates capital turnover and improves the supply chain. The speed of response will definitely enhance the company’s overall competitiveness.

[ad_2]