Solution based on UHF RFID uniform management system – Quan Shunhong

[ad_1]

For high-end hotels, hospitals and other units with high hygiene requirements, employees need to change and wash their work clothes regularly, and employees who do not need to be washed regularly need to be urged. The current manual management method cannot monitor whether employees change and wash regularly, and it is impossible to scientifically based on the attendance of employees. Dynamically adjust the frequency of changing and washing staff uniforms. The cases of using uniforms to commit crimes are also increasing. How to ensure that the uniforms of the unit will not be used by people with bad intentions after being lost has become a very important problem for many enterprises and institutions.

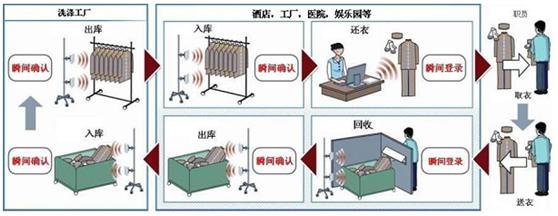

At present, places such as hotels, playgrounds, large factories, hospitals and other places have a large number of uniforms to be processed every morning. Employees need to queue up to the clothing room to receive uniforms, just like going to the supermarket to check out, they need to register and collect them one by one, and when they get off work Afterwards, it has to be registered and returned one by one. Sometimes there are dozens of people in line, and it takes a few minutes for each person. Moreover, the current management of uniforms basically adopts the method of manual registration, which is not only very inefficient, but also often leads to wrong receipt and loss.

The uniforms sent to the laundry factory every day need to be handed over to the laundry factory. The employees in the uniform management room hand over the dirty uniforms to the laundry factory employees. When the laundry factory sends back the clean uniforms, the employees of the laundry factory and the employees of the uniform management room need to check the type and quantity of the clean uniforms one by one, and both parties sign after the verification is correct. Every 300 pieces of uniforms require about 1 hour of handover time per day. During the handover process, the laundry quality cannot be checked, and it is impossible to talk about how to improve the laundry quality to increase the life of the uniforms and how to effectively reduce the inventory. Scientific and modern uniform management. Especially as people’s awareness of disease prevention and treatment continues to increase, it is a very arduous task to count the number of patients when they are handed over.

Ultra-high frequency (UHF) RFID has been widely used in various industries due to its characteristics of being able to read a large amount of time at a long distance and in an instant. At present, many hotels, hospitals, and amusement parks in the world have adopted this label to manage their uniforms, which not only effectively improves the efficiency of uniform management, but also greatly reduces the labor cost of uniform management.

Shenzhen Quan Shunhong Technology Co., Ltd., as the leading RFID brand–ThingMagic agent, provides the whole series of ThingMagic products to major operators and integrators, and always adheres to the business integration of “equipment + solution + service”. The mode, with automatic identification technology as the core, with the overall application solution of the Internet of Things as the guide, with the purpose of technical service application, effective integration of technology and application, and creation and realization of application value, provides mature, stable, professional, A complete package of detailed solutions and value-added services. At the same time, relying on the advantages of brand and technology, combined with rich technical service experience in the Internet of Things industry,existSmart Warehousing and Logistics,file informatization,Smart New Retail,Smart Manufacturing,Wisdom washing,asset Managementand other industry segments,From product selection, to solution design and system platform support, we provide users with comprehensive technical services that are easy to operate, highly stable, differentiated and innovative.

2. System composition

The system consists of the following parts:

1. UHF RFID reader:Linux RFID all-in-one readerFU-Astra-M9

2. UHF RFID antenna:Quan Shunhong (FUWIT) 8dbi circularly polarized external ultra-high frequency (UHF) RFID antenna

3. Electronic label:RFID Washable Tag

4. Server: used for collection and processing of background data

5. Software: uniform management software, database software

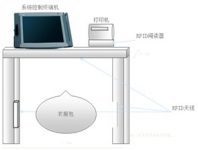

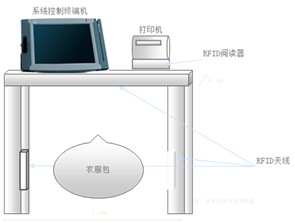

Equipment installation diagram

3. Successful Cases

1. The United States Hotel deploys an automated ultra-high frequency (UHF) RFID uniform management system

The UHF RFID uniform management system has been implemented in Rocksino Northfield Park, an entertainment venue under the Hard Rock Hotel in northeastern Ohio. Hard Rock wants to automate the control and management of the uniforms of more than 6,000 employees in the hotel.

Rocksino Northfield Park is a 200,000-square-foot gaming and entertainment venue that opened in December 2013 and features video lottery terminals (VLTs), entertainment, 4 dining options, and horse racing.

The Ultra High Frequency (UHF) RFID uniform management system utilizes rubber-encapsulated EPC Gen2 RFID tags attached to service personnel’s uniform property. Each tag has an ID number linked to a specific type of data associated with the item, as well as cleaning records.

If the garment is being washed or in use, the system can communicate and record the uniform location of each garment to manage inventory in real time. A unified ultra-high frequency (UHF) RFID uniform management system also records all uniform usage and laundry cycles, and predicts replacement requirements for accurate financial budgeting.

Rocksino Northfield Park in Hard Rock is a gaming, entertainment, dining destination with a staff of more than 750 people. The unified management system eliminates the cost of missing assets and reduces staff and laundry errors.

2. Implementation in a hotel

The uniform management of a hotel has always been manual registration, and uniforms are distributed to about several hundred employees every day. Every morning when I go to work, I have to queue up in the clothing room to get uniforms. Sometimes there are dozens of people in the queue, and it takes 3 minutes for each person. Just like going to a supermarket to check out, you need to manually register and borrow one by one.

In order to improve production efficiency, the hotel has introduced an ultra-high frequency (UHF) RFID uniform management system. The hotel labels each uniform and automatically uploads the data to the server through the chip. When a group of uniforms pass the reader inspection , to instantly read the model, size, color and other information of all clothes without scanning barcodes one by one as before. In addition, due to the use of tags for clothing management, the hotel has also adopted a clothing self-service system to improve efficiency. The hotel has set up the self-service system outside the clothing room. When employees pick up the clothes, they only need to go to the instrument, swipe the employee card, and then put a few uniforms in front of the UHF RFID reader to quickly confirm the loan. Out, the system greatly saves staff time to lend out uniforms. At the same time, if an employee gets the wrong uniform, the system can automatically remind the employee based on the style and size of the clothing recorded in the employee card. After adopting this system, the efficiency of the system has been improved by more than 50%.

widely applicable toSmart Warehousing and Logistics,Smart Manufacturing,Smart New Retail,Smart medicaland other industry segments.

Features:

> Give full play to the advantages of Thingmagic RFID module algorithm, its excellent tag chip compatibility, supports Alien H3, Impinj M series, NXP G2x* & G2i* series, and IDS Cool Log, RFMicron, Farsens, etc.sensor labelChip, label compatibility with industry significance;

> Support multiple protocols including EPC Gen2 &ISO 18000-6C, EPC ISO 18000-6B*, IP-X*, Gen2v2, AEI ATA* and other RFID protocol standards;

> Fully supports ThingMagic Mercury API embedded operating system, provides SDK of .NET and Java, and can easily customize the interface to control the reader as required.

2. RFID handheld

W9900A-X is a portable Android operating system integrating 1D or 2D barcode scanning, 4G full Netcom, GPRS, WIFI, BLUETOOTH, RFID functionsIndustrial-grade RFID intelligent data acquisition equipment. It adopts a 5.0-inch IPS screen with a resolution of 720*1280, high-definition full viewing angle, visible in the sun, and is equipped with high-performance Gorilla III secondary tempered glass to support multi-point capacitive touch screen.

Users can choose different functional modules according to actual needs to realize the collection of one-dimensional code, two-dimensional code and RFID data, and realize fast and effective data collection through various wired and wireless communication methods such as USB, GPRS, 4G, WIFI, and Bluetooth. transmission.widely used injewelry store,Garment Management,industrial manufacturing,Logistics warehouse management, asset ManagementinspectionWait.

Features:

> With a wireless voice and communication module, it can log in to the Internet and the cloud through a wireless network to realize real-time data processing and voice calls.

> Adopt ANDROID 7.0 embedded operating system, with friendly interface, simple operation, convenient use, intuitive scanning and recognition results, and can meet the needs of different users. At the same time, the real-time data transmission is realized, and the work efficiency is improved.

> Can be widely used in clothing management, industrial manufacturing, logistics warehouse management, asset management, inspection and other industries. The device is lightweight, suitable for one-handed work, and can be flexibly applied to any environment, simplifying business operation processes, improving work efficiency, reducing enterprise operating costs, and helping enterprises to facilitate mobile data management.

3. RFID printer

It supports reading, writing and printing of electronic labels with a minimum height of 12 mm, and is suitable for flexible anti-metal labels, flexible consumables compatibility, and high-quality print output, taking you into a wider application field.Products are widely used inAutomotive Manufacturing,Apparel Manufacturingfinancial services industry,Logistics and transportation,jewelry storeand other industry segments.

Features:

[ad_2]