12 Apr Walmart and the Past, Present, and Future of RFID

By now, you’ve probably heard of Walmart’s latest expansion to its RFID program. This announcement, and other major RFID success stories, cast the technology in the spotlight on a national level.

The retailing giant was the first to introduce the idea, but history shows, it was not an overnight success. Even so, businesses have eyed RFID for many years. If there were ever a time to invest in the technology, it is now.

To understand why, we need to investigate the past.

Walmart’s RFID journey

Walmart announced in 2003 that its top 100 suppliers must tag their pallets and cases starting by 2005. This announcement followed a successful trial run with an RFID system in 2002.

Anyone familiar with Automatic Identification and Data Capture (AIDC) during the time knows that Walmart’s initial vision was exciting yet ambitious, being that they were the first major retailer to require the technology [1]. Additionally, RFID was also relatively new in the supply chain space.

However, Walmart would later drop the mandate. Some suppliers reportedly stopped tagging their products because they believed Walmart was not acting on the data it had collected. Ultimately, though, tags were expensive, and the technology was not reliable enough. The initiative was officially put on hold in 2007 as a result [2].

With the challenging start, one can only ask…

Why try again now?

The technology has come a long way since Walmart first set out on its RFID venture 20 years ago.

Today, the technology is more developed, with an extensive selection of RFID inlays and tags available. Additionally, the industry better understands RFID, reducing its cost of adoption. There are still variables, but experts in the industry are aware of them and know how to bypass them.

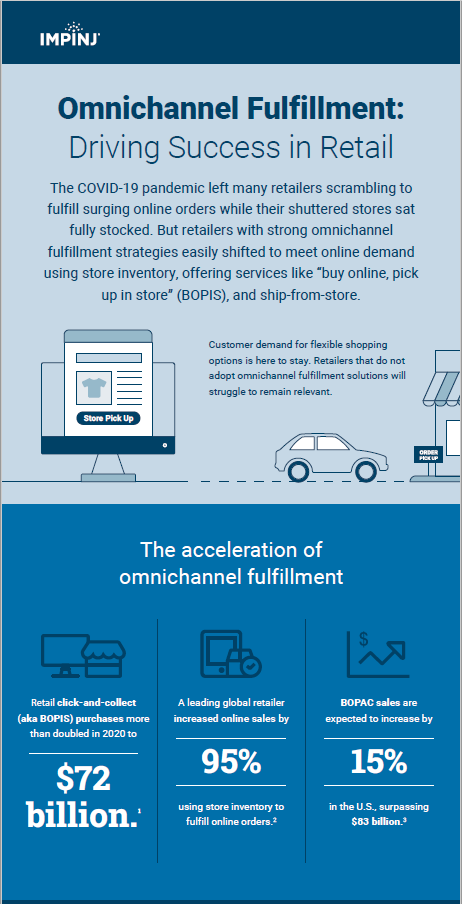

The pandemic accelerated the Buy Online Pick Up in Store (BOPIS) model, which accounted for $72 billion in purchases in 2020, having greater inventory accuracy grew ever more important. Walmart saw the writing on the wall: With this model of shopping growing in popularity, RFID was the key to delivering accurate inventory levels and keeping customers happy.

In 2020, Walmart tested RFID again in its apparel departments. This new attempt significantly reduced nil picks, supported faster fulfillment, facilitated better online availability, and increased customer satisfaction.

What to expect: a future of opportunities

The RFID mandate may seem like is yet another box for suppliers to check. They will comply, shelf the project, and won’t think about it again. This mandate, however, allows suppliers to take advantage of RFID in their workflows.

OPPORTUNITIES FOR MANUFACTURING

Walmart is not the only retailer that requires RFID – and you can expect many to follow suit. Nordstrom recently revealed its own plans to mandate RFID, although it has not yet defined a timeline. We fully expect more major retailers to move in this direction.

As more follow in Walmart’s footsteps, we predict retailers purchasing your manufactured goods will also start asking for RFID-labeled items. This positions manufacturing companies to offer a tagging service for distributors, labeling the products for them so they can begin tracking upon receiving them: an attractive offer that will no doubt put you ahead of the competition.

OPPORTUNITIES FOR DISTRIBUTING

There are hundreds of boxes, pallets, and products in your warehouse, all of which are important to track. Now, when manufacturers tag their products before they leave the plant, all distributors will need to do is implement readers and software to capture their data. The data captured will provide actionable insight into your stock, whether it be for forecasting or locating purposes.

To make the most of an RFID system and maximize visibility, we recommend tagging all your items. One expert from Forrester suggests doing this when demand for tagged items increases to at least 40% [2]. This is not only because it is cost-effective, but it prevents you from accidentally creating a split system.

When Walmart first attempted RFID, distributors kept the EPC-tagged items separately from the rest of their inventory. This lack of standardization caused confusion and reduced visibility into their stock.

Even if you are not at a point yet to fully implement RFID, the Walmart mandate puts you well on your way. As we’ve seen over the past few years, RFID helps companies maintain a strong omnichannel fulfillment operation during several waves of disruptions. It could do the same for you.

The next steps

Whether you need to comply to Walmart’s latest RFID expansion, or you want to explore RFID for your business, contact RFID China to speak to a solutions consultant. We will help chart a path to automation by incorporating RFID into your supply chain.