RFID-based Checked Baggage Process Tracking Technology and Application in Wuhan Tianhe Airport

[ad_1]

Wuhan Tianhe Airport has started to use RFID tracking technology for checked baggage since 2008, realizing highly reliable sorting during the check-in process. In 2014, Wuhan Airport upgraded the original RFID tags to use disposable RFID luggage tags; in 2017, the T3 terminal baggage sorting system was gradually built to track the entire baggage process, realizing the full path tracking from check-in to the aircraft warehouse.

1. Background

Wuhan Tianhe Airport took the lead in using RFID tracking technology for checked baggage among similar domestic airports in 2008, achieving a 99% correct sorting rate of baggage in the check-in and sorting process. In the early days of RFID use, Wuhan Airport adopted IC-type RFID cards that can be read and written repeatedly. Under the environment of 22℃, this card has a minimum of 100,000 write times and unlimited read times. The data is kept for 10 years.

Although IC-type RFID can be used repeatedly, reducing the cost of using RFID tags. However, the following problems were found in actual use:

1. In use, the RFID card will inevitably be squeezed by the suitcase, causing the tag to be bent and deformed and damaged, causing the RFID reading workstation to be unable to read the luggage information in the tag. According to incomplete statistics, the IC card RFID damage rate of Wuhan Tianhe Airport reached 15% from 2008 to 2013.

2. Due to the lack of RFID chip testing equipment and management measures in the early stage, it is impossible to screen RFID chips that do not meet the standards of Wuhan Airport, which causes some non-compliant RFID tags to enter the use link, resulting in occasional abnormal shutdown of the RFID reading workstation, affecting Correct sorting of baggage.

3. The check-in staff made mistakes in the operation, which resulted in the failure to write baggage information, which caused the baggage sorting to be incorrectly sorted.

2. Improvement measures

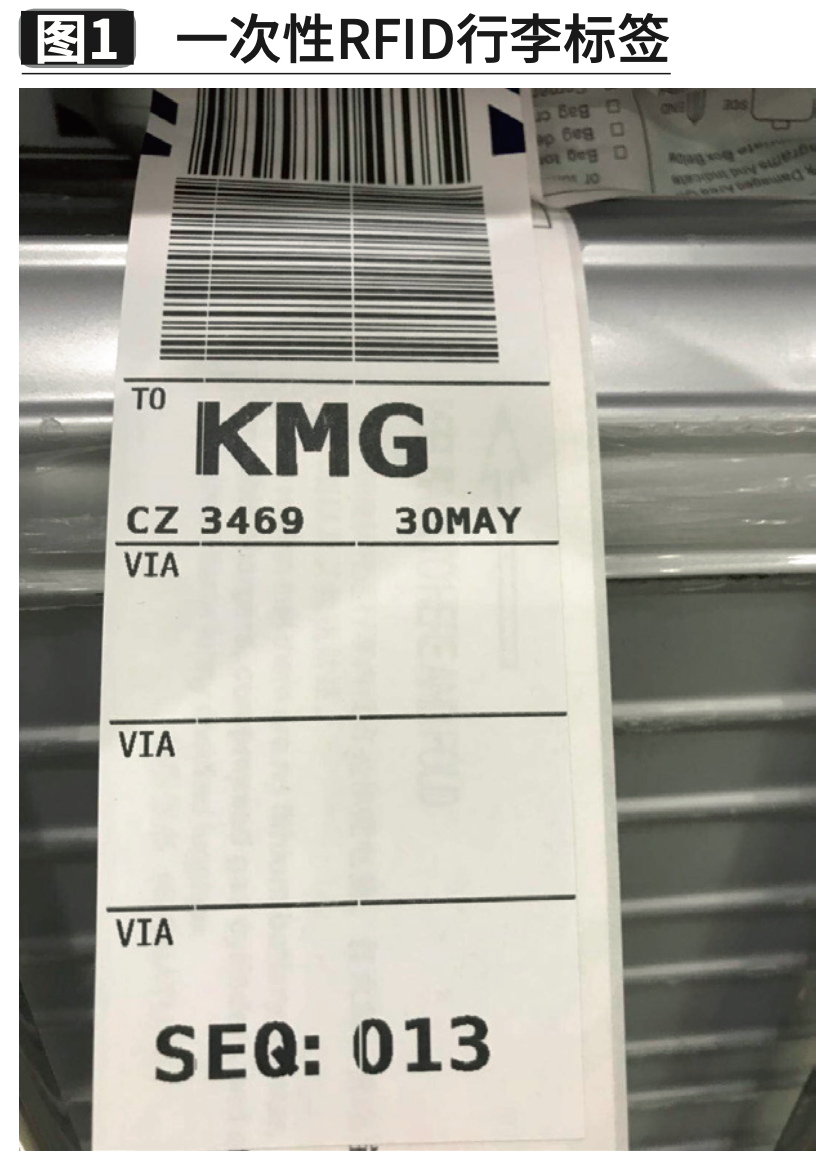

With the popularization of RFID technology, the price of RFID chips has dropped to a large extent. Wuhan Airport began to select disposable RFID luggage tags (see Figure 1) and its supporting luggage tag printers to implement RFID chips directly implanted in luggage tags, optimize the operation process of check-in personnel, and reduce the impact of human error on information writing .

Since June 2014, all domestic check-in counters at Wuhan Tianhe Airport have fully implemented disposable RFID luggage tags, and the correct luggage identification rate can reach 99.8%.

Since the initial design of the baggage check-in baggage system for the T3 terminal of Wuhan Tianhe Airport in 2015, the relevant construction and operation and maintenance departments of Wuhan Airport have begun to study the whole-process baggage tracking system based on RFID technology. At present, the whole-process baggage tracking system is gradually being implemented. After the project is completed, the whole-process tracking from the passenger check-in counter to the aircraft cargo warehouse can be realized. In the future, it can rely on RFID full-process baggage tracking data to provide airlines and passengers with baggage inquiry services, and improve the experience of passengers’ baggage check-in service.

In 2017, Wuhan Tianhe Airport integrated the design requirements of the baggage tracking system into the construction of the T3 terminal baggage system. In 2019, Wuhan Tianhe Airport began to build a full-process baggage system. Use RFID electronic tags, RFID card readers, barcode reading and other technical means to deploy data collection points in the outbound baggage delivery process and inbound baggage outbound process, collect relevant data of each link of baggage check, and complete the quick scan of the baggage. Confirm to ensure that the luggage is sorted correctly. Through information collection, a cloud data platform is built to provide baggage security personnel with real-time monitoring, message early warning and statistical analysis, leading to error links, and reducing the probability of abnormal baggage. Passengers can check the location and status of their luggage in real time and experience a better luggage service experience.

3. Expected goals

The whole baggage process system implemented by Wuhan Tianhe Airport (as shown in Figure 2) will realize baggage information tracking from the departure passenger at the check-in counter to the destination passenger’s baggage collection. Each key node is completed by RFID tracking technology. Real-time baggage data collection fully meets the requirements of the baggage tracking data node required by IATA 753, and at the same time realizes the data sharing of all related parties.

After the baggage tracking project is completed, the following goals can be achieved:

1. Achieve real-time path recording in scenarios such as counter check-in baggage tag writing, tag reading, chute confirmation, baggage loading confirmation, and airplane cargo warehouse confirmation.

2. Realize 100% path tracking of outbound baggage. Each baggage can be tracked in real time to minimize the occurrence of baggage misloading, missed loading and wrong loading.

3. Due to the use of RFID technology for tracking, automatic sorting can be realized in the whole process, which effectively reduces the labor intensity of baggage sorting personnel and improves the efficiency of personnel sorting.

4. Real-time reminder for special baggage, which is convenient for sorting personnel to process in time.

5. After the flight is closed, the system will automatically generate a baggage data report to avoid data statistics errors caused by human errors.

6. Based on the baggage tracking data in the whole process, real-time baggage routing information query can be provided to airlines and passengers, and the convenience of using baggage query business can be improved.

7. The system has a baggage detection function, which can quickly find the target baggage among many baggages.

8. Build an interconnected baggage tracking data platform, establish a unified RFID data tracking message standard, and provide baggage data services to airlines and airport ground service companies.

Fourth, process design

In order to achieve the above functions, the baggage tracking system needs to deploy several data collection points in the outbound baggage delivery process and the inbound baggage outbound process.

1. Baggage departure process (baggage delivery)

(1) Check-in and consignment link

This link mainly collects baggage pictures, binds baggage information, and supplements and perfects special baggage information such as VIP, over-regulated, and door check-in. At present, all 120 baggage check-in counters in the T3 terminal are equipped with RFID baggage tag printers and disposable flexible RFID electronic tags.

During passenger check-in, in addition to printing luggage tags, the printer can also write luggage information into the chip built into the RFID luggage tag.

(2) Safety inspection link

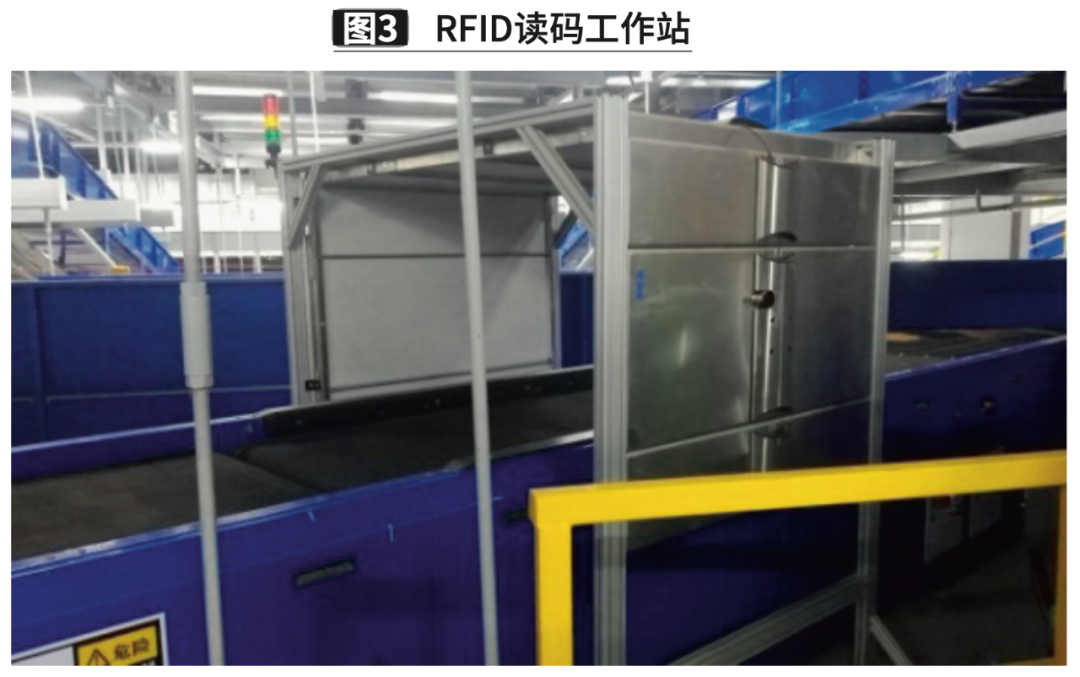

At present, the T3 baggage sorting system has covered the data collection of level 1 to level 4 security check information, and the automatic collection point of level 5 security check baggage information has been gradually installed. In addition, the baggage system has installed RFID code reading workstations (48 in total) at other important baggage tracking information nodes (AT, CT, and sorter induction line), as shown in Figure 3, to realize the full route tracking of baggage in the baggage sorting area.

(3) Luggage loading link

At the end of the chute, the information of the tractor and the flatbed is bound by hand, and the loading luggage information is collected by reading the luggage RFID tag. In the luggage loading link, there are two information collection points for luggage reconfirmation and trailer flatbed binding.

① Baggage reconfirmation information collection point

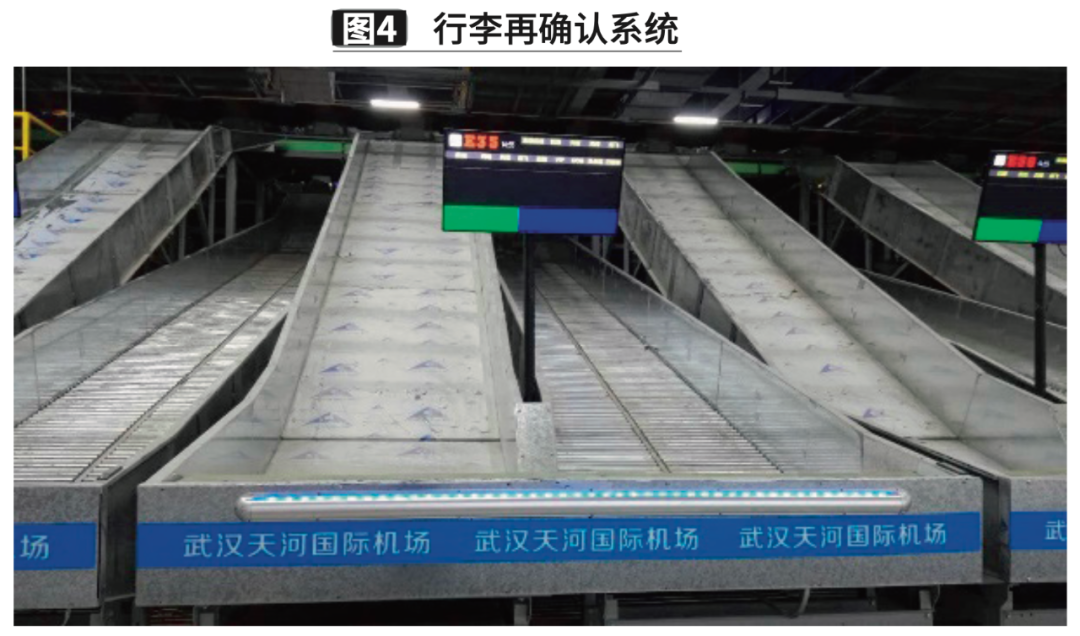

Baggage reconfirmation is a set of systems that adds a confirmation link to the sorting exit of the automatic baggage sorting system to prevent the wrong delivery or loss of the baggage. Due to the use of RFID antennas in this field, only a few additional operations are needed to basically achieve automated baggage information comparison, which reduces the possibility of occasionally incorrectly sorted baggage being loaded and sent to the wrong plane. The probability of baggage arriving on the same plane as the passenger.

The baggage sorter picks up the baggage from the sorting chute. The antenna at the bottom of the chute (as shown in Figure 4) will automatically read the baggage barcode information, and the information system will compare the read baggage barcode with the currently allocated flight on the chute , If the comparison is successful, the control antenna lights up green and buzzes for 1 second, and at the same time records the location information of the luggage loaded on the car, the chute information screen will also display the barcode already loaded; if the comparison fails, the control antenna lights up red The lamp will beep for 3 seconds, and the position information of the baggage in the wrong chute will be recorded. The chute information screen will also display the barcode error.

②Collection of binding information on baggage trailer flatbed

Sorting personnel use the wireless handheld terminal APP (Figure 5) to scan the handheld terminal RFID to scan flat RFID metal tags and luggage RFID tags to realize the binding of luggage and trailers.

(4) Baggage leaving the sorting area

An RFID antenna is installed at the exit of the sorting area. When the baggage security vehicle leaves the sorting area, RFID will automatically read the information of the tractor and the platform, and record the operation information of the trailer and the platform.

(5) Luggage loading link

Collect baggage information through wearable devices (RFID reading vests). Use the strength of the radio frequency signal to quickly locate the luggage in the cabin.

2. Baggage entry process (baggage out of the cabin)

(1) Luggage out of the cabin

Under the machine, the sorting personnel hold the binding tractor flatbed information, and collect the cabin baggage information through the wearable device (code scanning gloves)

(2) Enter the sorting area

RFID antennas are installed in the entrance area of the sorting area to read the information of tractors and slabs entering the sorting area, and record the operation information of the trailers and slabs out of the warehouse.

(3) Baggage delivery

In the baggage arrival sorting area, the sorting personnel collect the information of the dropped baggage through the wearable device.

(4) Baggage visualization

A camera is installed at the baggage drop-off area at the port, and passengers can supervise whether the drop-off operation is standard while waiting for the baggage on the pick-up carousel.

(5) Baggage claim

When the baggage arrives at the pick-up surface of the carousel, the staff can quickly verify the picked-up baggage through the handheld terminal.

Five, implementation effect

At present, the whole-process tracking project of the baggage system is being implemented gradually as planned. The baggage sorting system, baggage loading and arrival baggage visualization have been completed and put into use. Data collection such as baggage trailer entry and exit, cabin baggage loading and unloading, and arrival baggage delivery are progressing steadily.

As far as the use of some systems in the current baggage tracking project has been completed, the baggage tracking rate has reached the design expectations, and the baggage tracking information has been covered from the check-in counter to the baggage trailer. The sorting personnel of various airlines can inquire and grasp the exact path of the baggage, which is convenient for baggage loading and baggage search, minimizes baggage mispacking and missing baggage, and improves the travel experience of passengers.

Six, future planning

In the later period, Wuhan Tianhe Airport will open up data jams in all links, realize the interconnection of baggage tracking data in the whole process, and establish a comprehensive baggage information service cloud platform to meet the business needs of subsequent passenger inquiries, baggage tracking, and baggage transfer across airlines.

On the basis of the information system cloud platform, Wuhan Tianhe Airport will further optimize the existing baggage collaborative operation mode, define the business logic of collaborative decision-making, and establish the airport collaborative operation business (data) standards and technical specifications. In addition, relevant guarantee units can optimize the process through data mining and analysis on the cloud platform, thereby improving the quality of service and improving the level of baggage service at the entire airport.

With the development of the Internet of Things technology, RFID will have a wide range of application scenarios in civil aviation services, equipment maintenance, production operations, and safety protection. Wuhan Tianhe Airport will provide passengers with better services, actively build a “smart airport”, and use more RFID equipment to make it more abundant in airport applications.

[ad_2]